Floating target mechanism for radiation source

A technology of ray source and driving mechanism, which is applied in the field of X-ray imaging, can solve the problems of inability to adjust the position of the target, pitting of the target surface, etc., and achieve the effect of solving the problem of target function failure, shrinkage deformation, and reducing moving friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following describes the embodiments of the present invention in detail. This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation modes and specific operation procedures, but the protection scope of the present invention is not limited to the following implementations example.

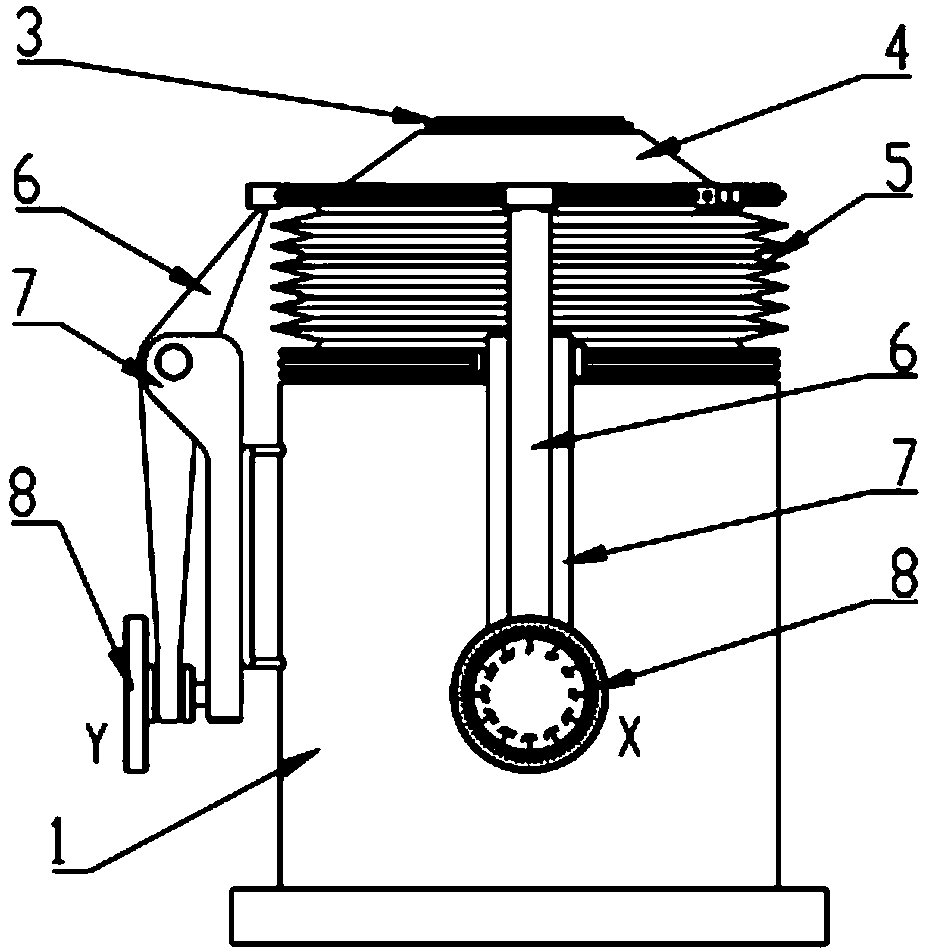

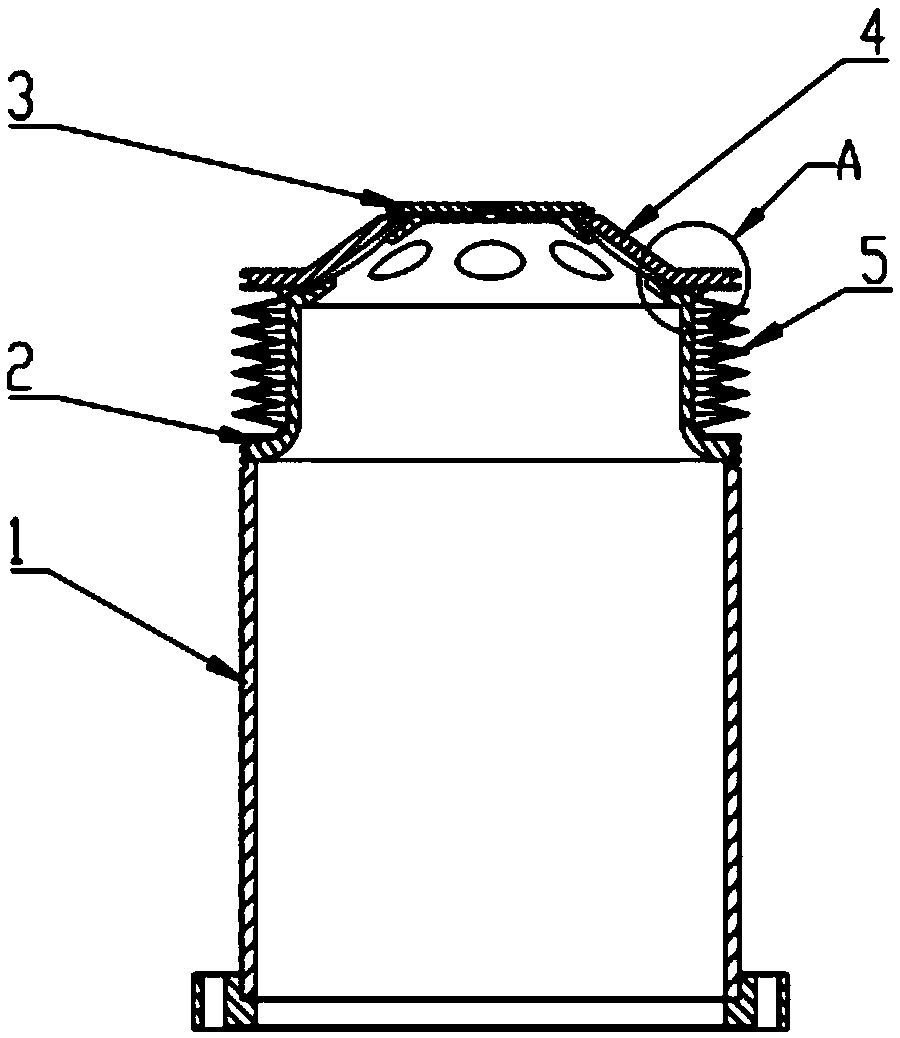

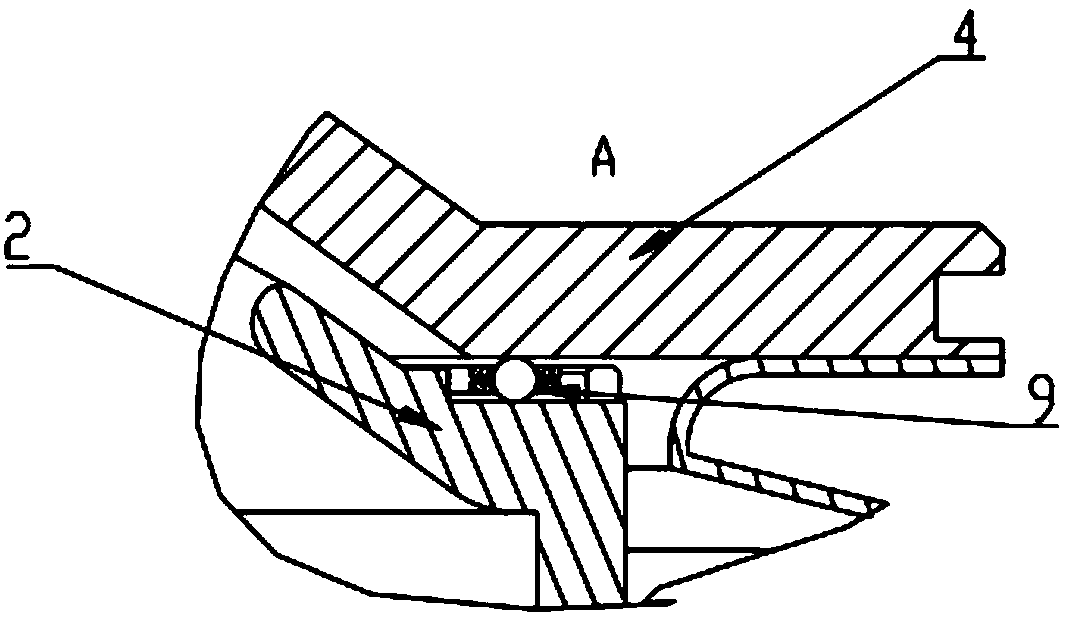

[0024] Such as Figure 1~3 As shown, this embodiment includes a ray source housing 1, a tube shell inner cover 2, a floating target 3, a target base 4, an elastic compression tube 5, and a driving mechanism; the upper part of the target base 4 is airtightly welded and connected to the floating target 3. , The lower part of the target base 4 is airtightly welded to the elastic compression tube 5, the target base 4 is located on the tube shell inner cover 2, and the lower part of the tube shell inner cover 2 is airtightly welded to the radiation source shell 1, the elastic compression tube 5 is sleeved outside the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com