Prediction method of low-magnification coarse-grain structure distribution in near-alpha titanium alloy

A technology of coarse grain structure and prediction method, applied in the forging field of titanium alloy forgings, can solve the problems of uncontrollable low-magnification coarse grains, solve the problem of uncontrollable low-magnification coarse grains, reduce low-magnification coarse grain areas, and improve material utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, exemplary embodiments, features, and performance aspects of the present invention will be described in detail with reference to the drawings. The same reference signs in the drawings indicate elements with the same or similar functions. Although various aspects of the embodiments are shown in the drawings, unless otherwise noted, the drawings are not necessarily drawn to scale.

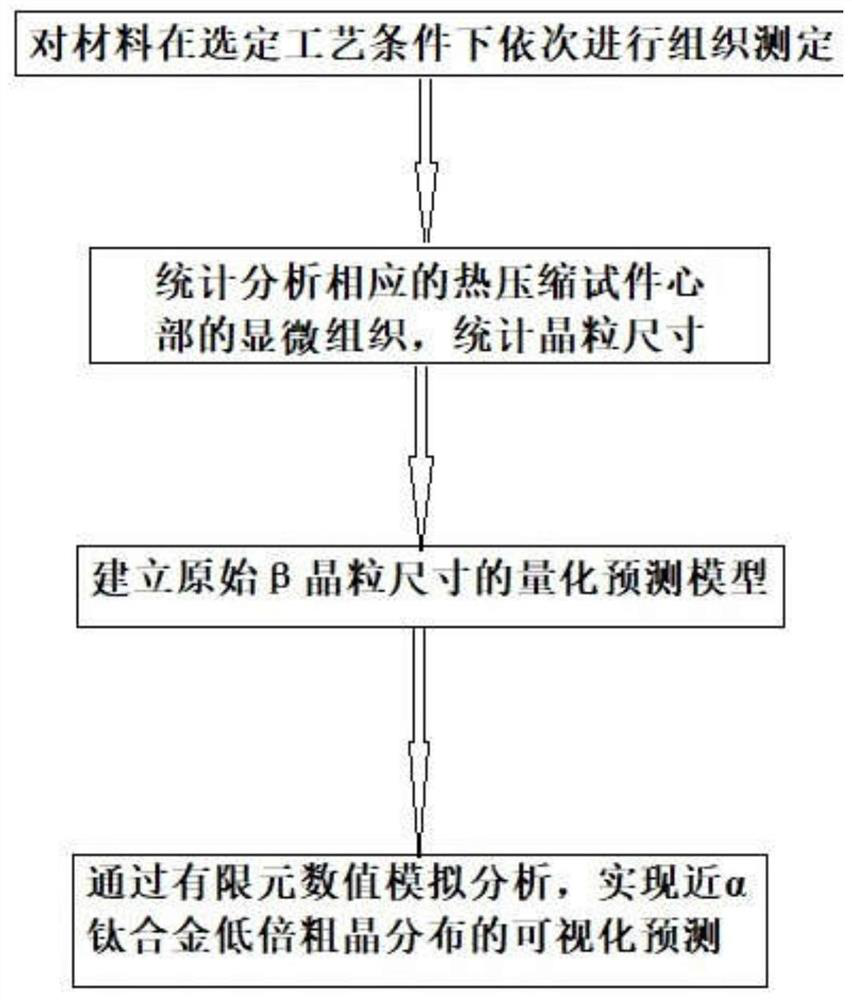

[0050] Such as figure 1 As shown, a method for predicting the distribution of a low-magnification coarse-grained structure of a near-α titanium alloy includes the following steps:

[0051] S1. Conduct organization determination of materials in sequence under selected process conditions:

[0052] S11. Isothermal thermal compression test:

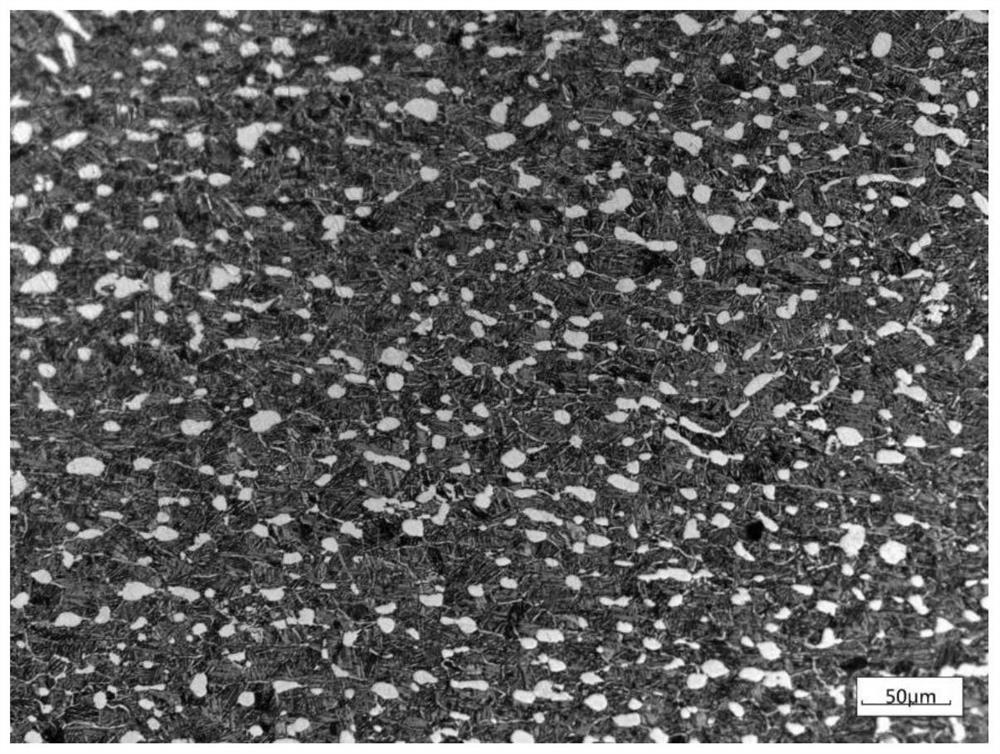

[0053] A cylindrical specimen is cut from a nearly α titanium alloy forging rod, and a constant strain rate isothermal thermal compression test is performed. The deformation temperature is selected from more than 3 temperature points in the interval of 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com