An electronic product assembly process flow and an assembly lean process design method

A technology of electronic products and process flow, applied in CAD circuit design, computer-aided design, calculation, etc., can solve problems such as reduced attention to process documents, insufficient experience, and operational quality problems, so as to improve production efficiency and stability, The effect of reducing the difference in process quality and good inheritance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

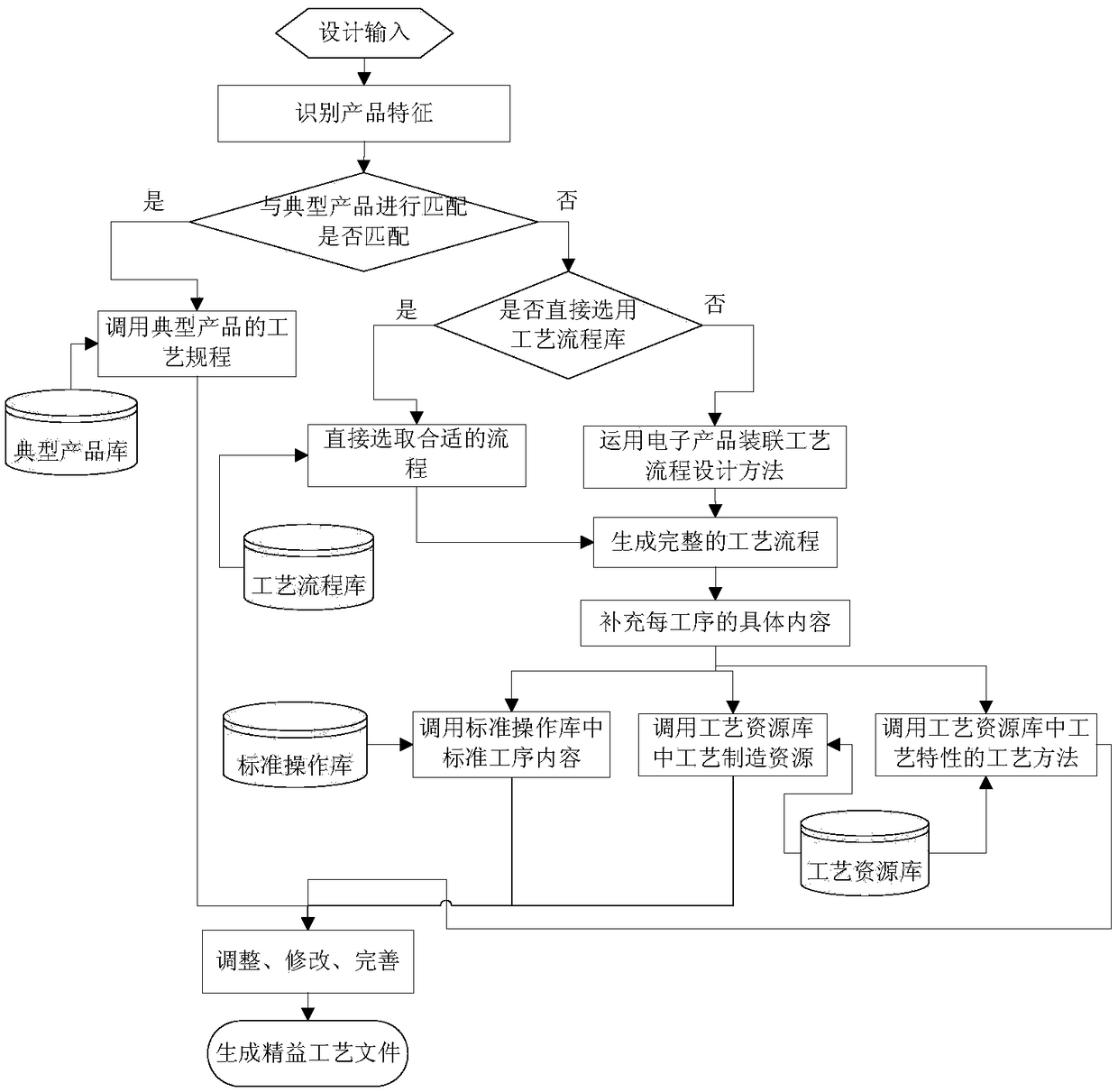

[0064] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

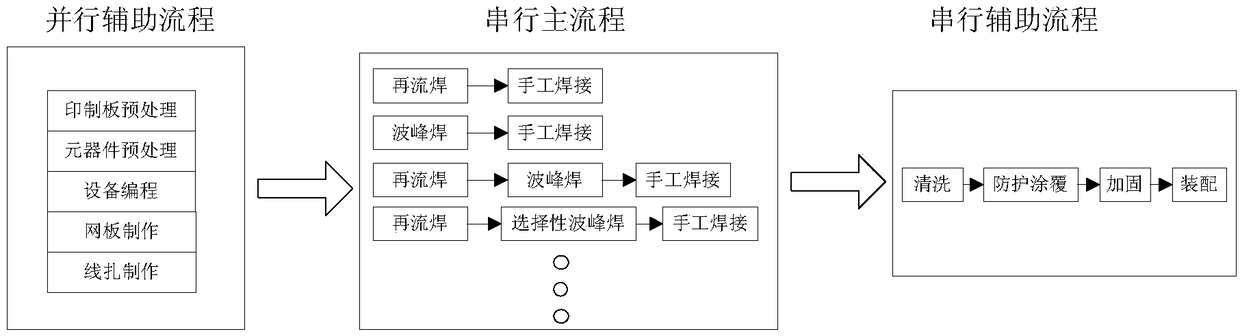

[0065] 1. Electronic product assembly process design method

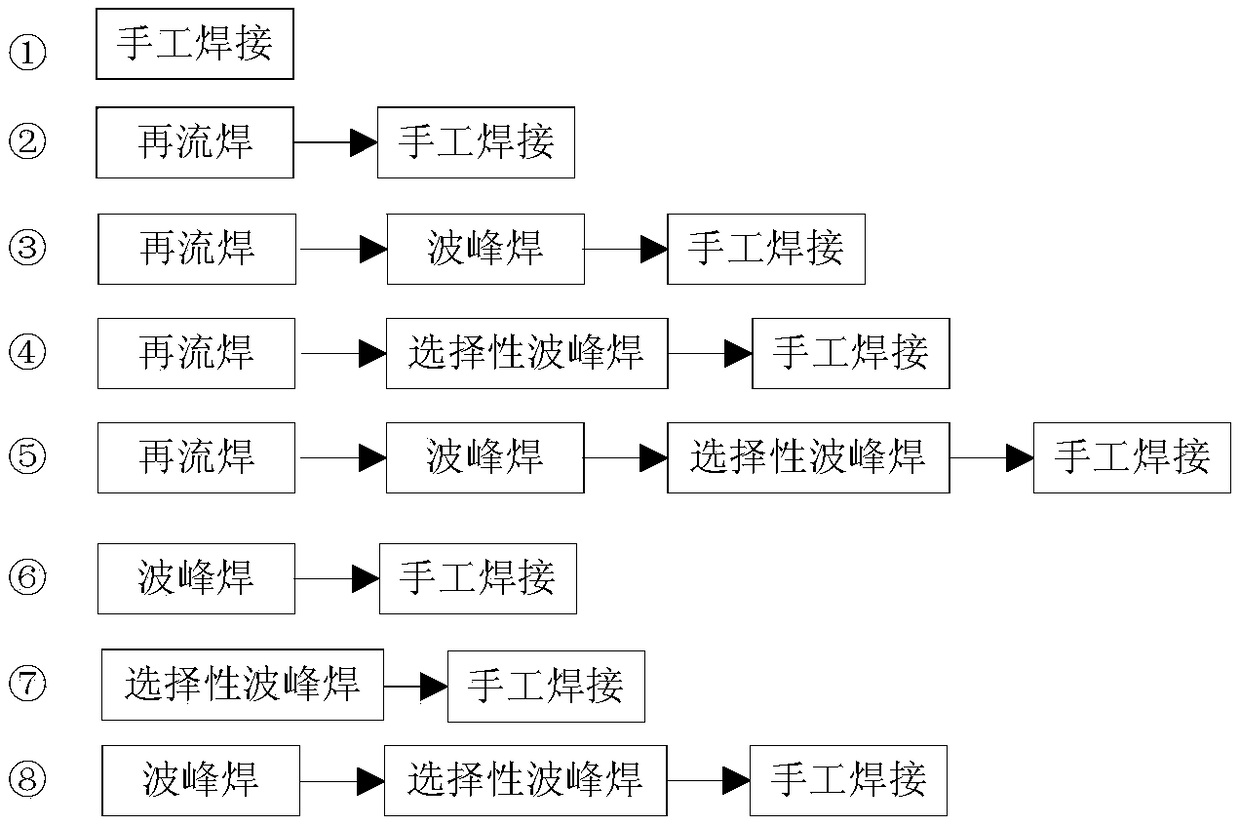

[0066] In electronic products, components are divided into through-hole components and surface mount components according to the installation form; welding methods can be divided into manual welding and automatic welding according to different operation methods. The manual welding method is relatively simple in operation and low in cost. It is relatively low, but it has high requirements for personnel skills, high labor costs, and is not suitable for mass production; especially for surface mount components, such as components with packaging structures such as BGA, it is no longer possible to rely on manual soldering.

[0067] Automatic soldering methods are mainly divided into wave soldering and reflow soldering. Wave soldering is mainly suitable for soldering through-hole components. Reflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com