Reverse impeller hydraulic power design method

A technology of reverse design and impeller, applied in design optimization/simulation, calculation, image data processing, etc., can solve problems such as failure to ensure expected effect, waste of manpower and material resources, and high design cost, so as to reduce unpredictability, reliable performance, and time-saving and the effect of frequency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

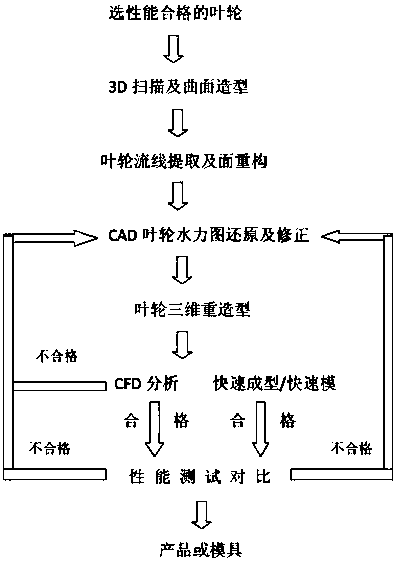

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0028] see figure 1 , the present invention provides a hydraulic reverse design method for an impeller, characterized in that: the first step is to determine the design parameters, the design parameters are as follows:

[0029] Flow Q = 30m3 / hs

[0030] Head H =6m

[0031] Speed n = 2850r / min

[0032] Efficiency η = 45.6%;

[0033] The second step: 3D scanning and surface modeling;

[0034] The third step: impeller streamline extraction and surface reconstruction;

[0035] Step 4: Restoration and correction of the hydraulic diagram of the CAD impeller, and correct the extracted streamlines with circular arcs, while ensuring smooth streamlines of the axial surface and plane projection diagram;

[0036] Step 5: 3D remodeling of the impeller;

[0037] The sixth step: CFD analysis and rapid prototyping or rapid mold, when the CFD analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com