A memory strip mounting structure for automatic lifting and lowering seals

An automatic lifting and installation structure technology, which is applied in the computer field, can solve problems such as user troubles, dust accumulation in memory sticks, blue screens, etc., and achieve the effects of preventing dust from entering, ensuring stable work, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

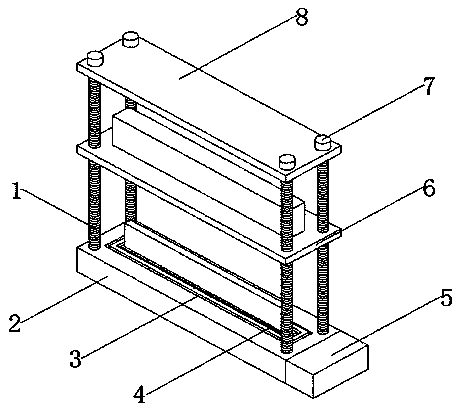

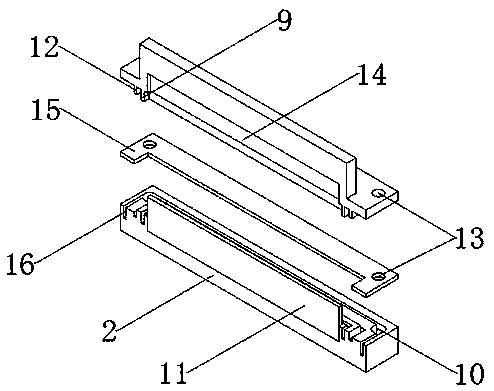

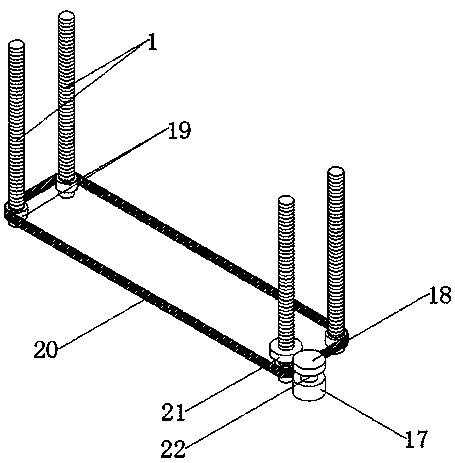

[0012] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

[0013] An automatic lifting and sealing memory stick installation structure, including a lifting column 1, a base 2, an outer sealing groove 3, an inner sealing groove 4, a power compartment 5, a sealing cover 6, a bearing 7, a fixing plate 8, and an inner sealing protrusion 9 , lifting column groove 10, memory stick 11, outer sealing protrusion 12, lifting column perforation 13, memory stick groove 14, base sealing plate 15, track groove 16, motor 17, driving gear 18, track gear 19, track 20, Transmission gear 21, rotating shaft 22, the memory bar 11 is set in the middle of the base 2, the inner sealing groove 4 is set outside the memory bar 11, the outer sealing groove 3 is set outside the inner sealing groove 4, and a lifting column groove 10 is set at each of the four corners of the base 2 , the lifting column groove 10 is connected throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com