Optical cable spraying process and corresponding spraying device thereof

A technology of spraying device and optical cable, which is applied in the field of spraying device and optical cable spraying technology, can solve the problems of increasing the weight of optical cable, increasing the difficulty and cost of optical cable, and achieving the effect of reducing the overall weight, difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

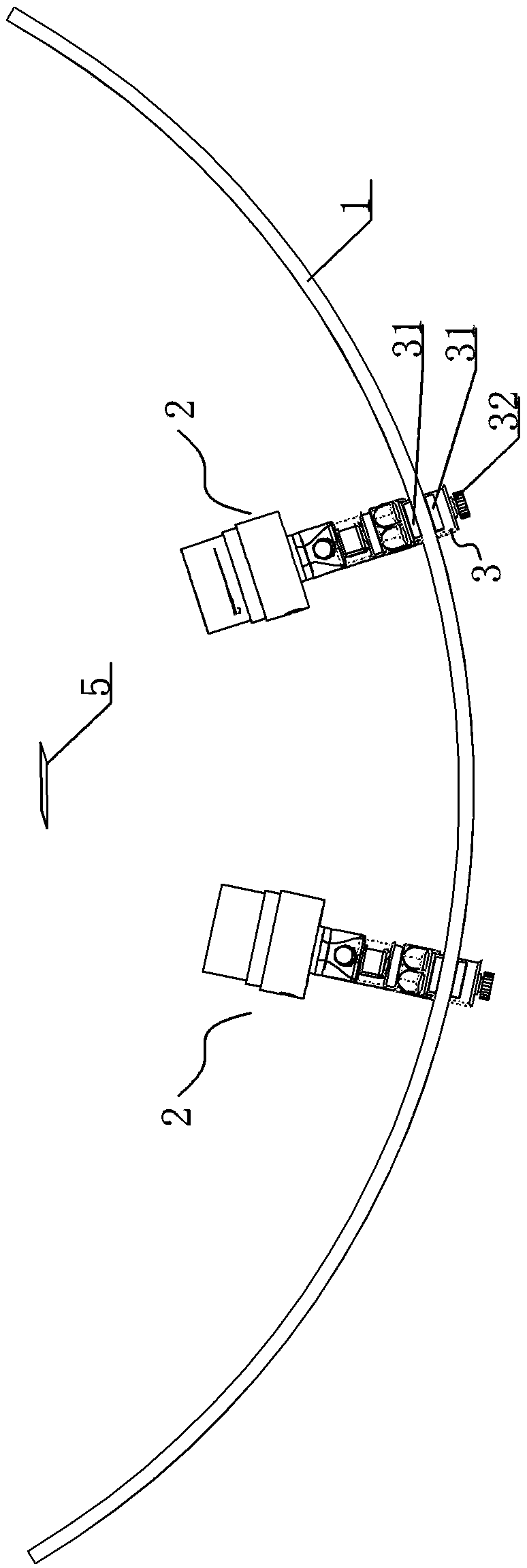

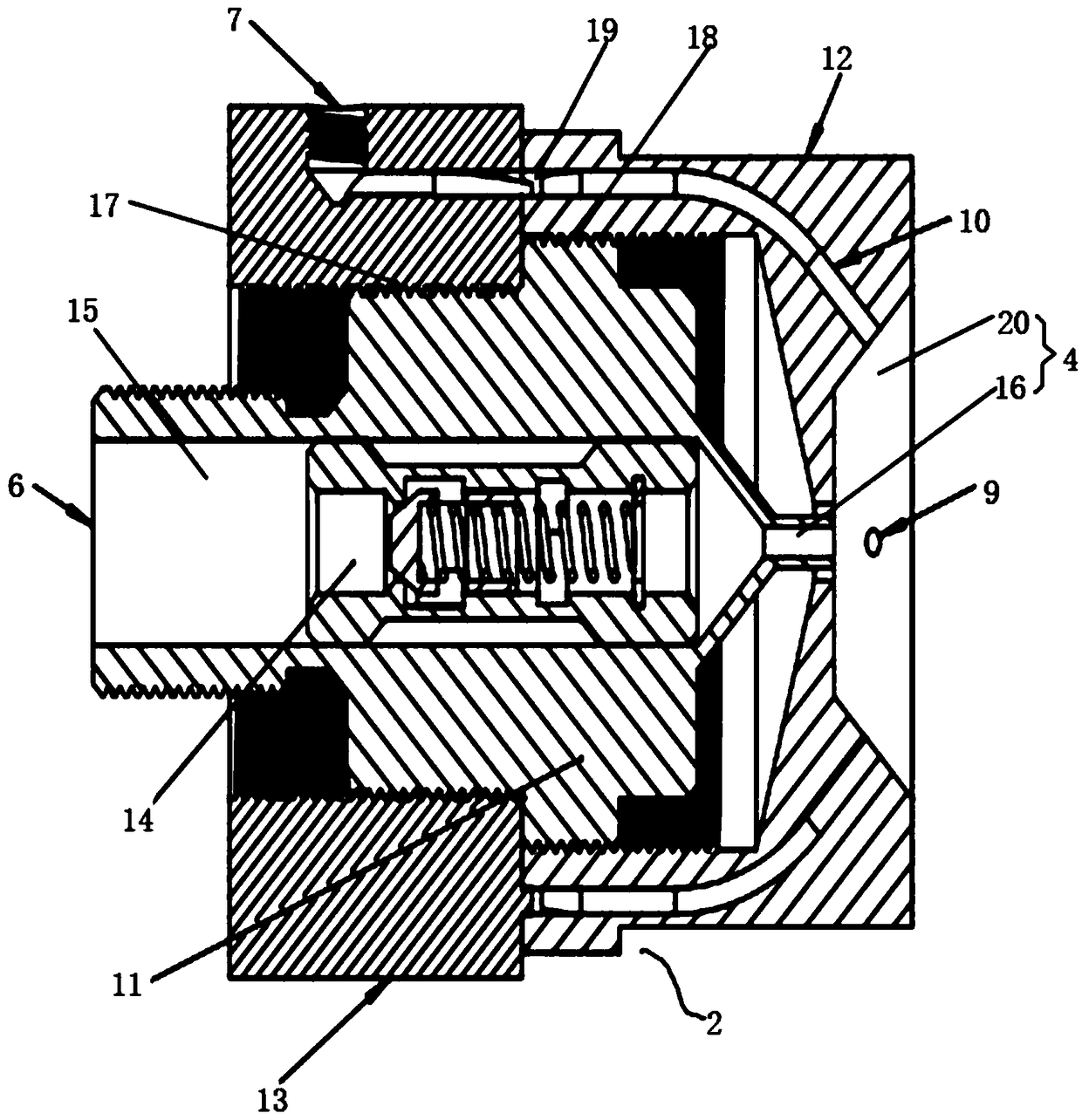

[0020] A fiber optic cable spraying process: it pre-sprays the ointment on the outer peripheral surface of the strengthening member forming the cable core, and sprays the ointment on the inner surface of the composite tape facing the cable core in advance, and then arranges the strengthening member and the optical fiber on the The casing forms the cable core, and then during the production of the sheath process, the grease-sprayed side of the composite tape is coated on the outer ring surface of the cable core, and the sheath is coated on the non-grease-sprayed outer surface of the composite tape.

[0021] When spraying, the ointment is delivered to the spray gun through the ointment pump, and the ointment mist spray effect is controlled by the ointment pressure cylinder, the spray pressure cylinder and the mist spray gun while the spray gun is being sprayed, and the intermittent mist spray is controlled by a solenoid valve , to reduce the overall weight of the cable while ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com