Observation equipment for microscopic features of rock fracture seepage based on 3D (three-dimensional) printing technology and observation method

A 3D printing and rock mass fissure technology, which is applied in measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of not being able to analyze the seepage characteristics of rock mass fissures from a microscopic point of view and visually observe seepage flow and other problems, to achieve the effect of saving manpower and material resources, saving experimental water, and less turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] An example of the present invention is specifically described below in conjunction with accompanying drawing:

[0058] 1. Overall

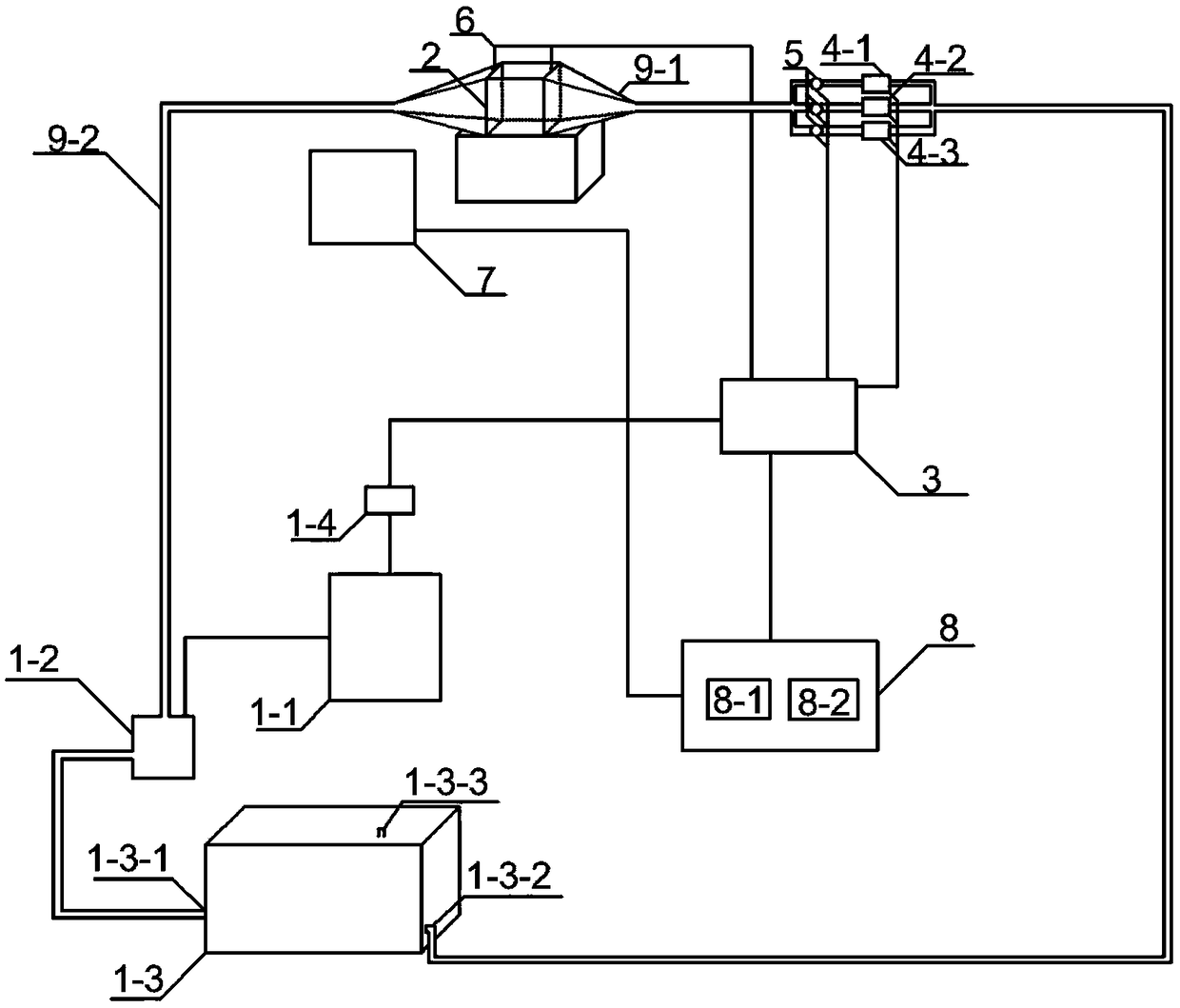

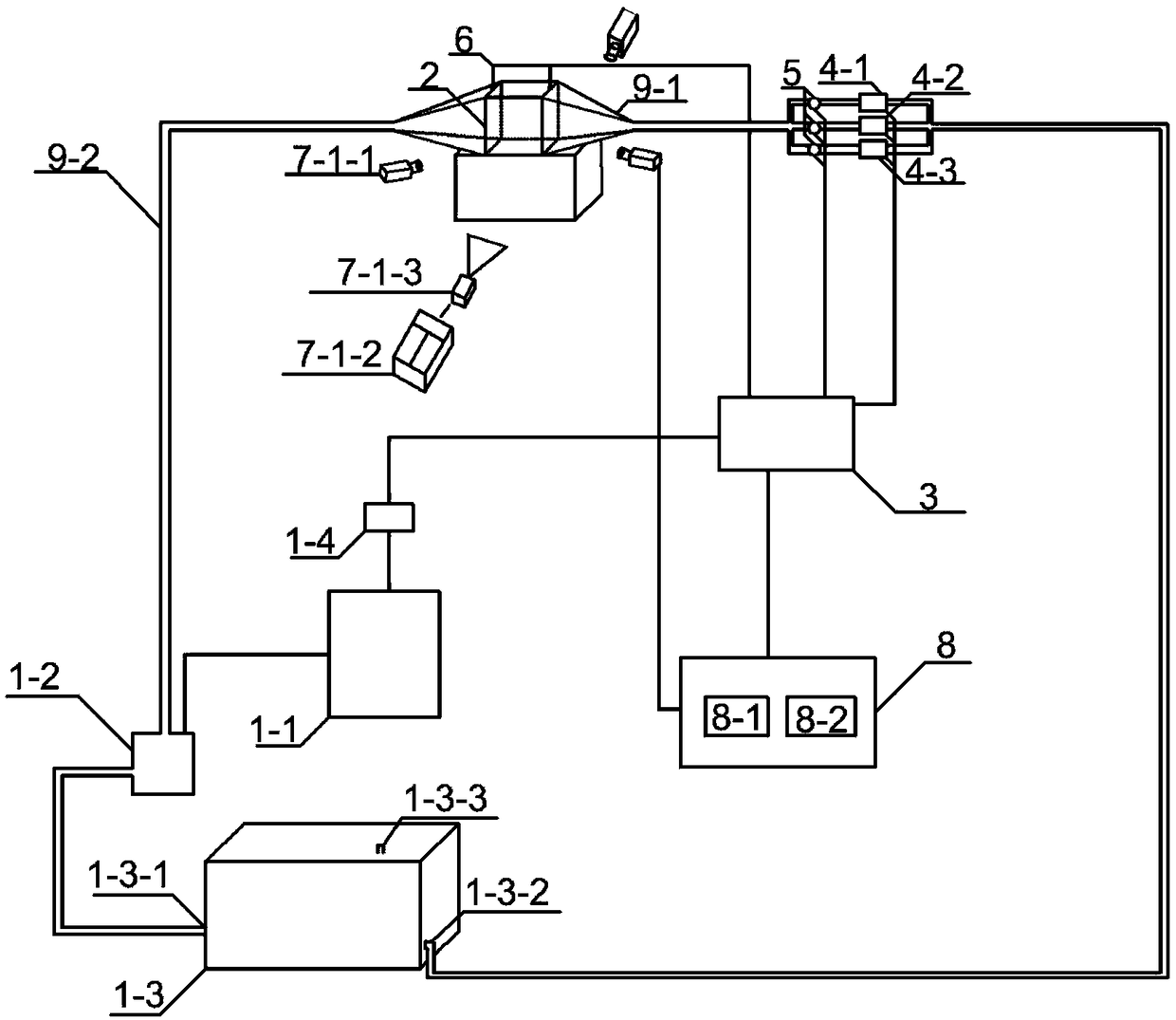

[0059] A rock mass fissure seepage microscopic feature observation equipment based on 3D printing technology of the present invention consists of a water supply system (1), a sample device (2), a control board (3), a flow meter (4), and a solenoid valve (5) , pressure sensor (6), microscopic measurement system (7), computer system (8), pipeline system (9);

[0060] The water supply system (1) mainly includes a servo motor (1-1), a water pump (1-2), a water storage tank (1-3), a servo motor controller (1-4); the water storage tank (1-3) There are water outlet (1-3-1), water inlet (1-3-2) and exhaust port (1-3-3) respectively;

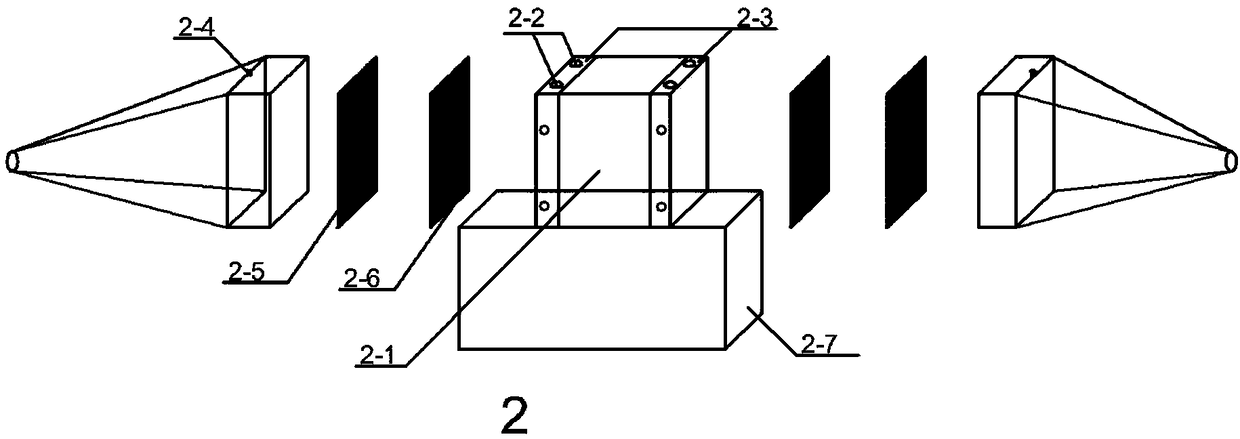

[0061] The sample device (2) mainly includes a transparent resin sample (2-1), bolts (2-2), rubber gasket (2-3), pressure measuring port (2-4), deflector (2 -5), filter screen (2-6), sample support (2-7);

[0062]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com