Boiler sampling device of coal-fired unit of thermal power plant

A technology for a coal-fired unit and a sampling device, which is applied in the field of fly ash sampling, can solve the problems of device blockage, affect the next sampling, and be difficult to clean, and achieve the effect of avoiding blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

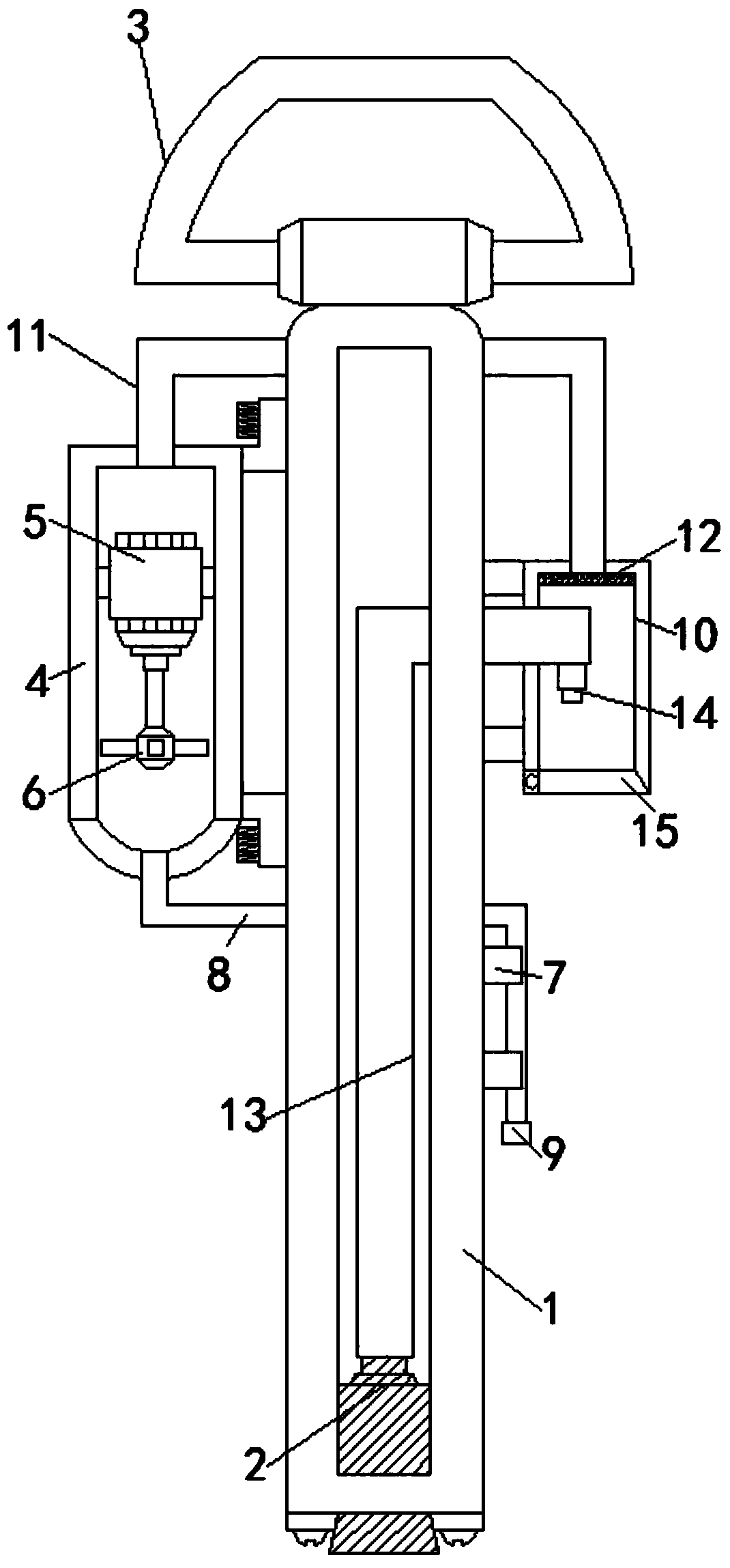

[0016] Embodiment 1 of the present invention: as figure 1 and figure 2 As shown, a coal-fired unit boiler sampling device in a thermal power plant includes a pipe body 1, the bottom of the pipe body 1 is fixedly installed with a suction cup 2 that penetrates and extends to the inside of the pipe body 1, and the top of the pipe body 1 is fixedly installed with a Handle 3, the left side of the pipe body 1 is fixedly installed with an installation cylinder 4, the interior of the installation cylinder 4 is fixedly installed with a motor 5, and the output shaft of the motor 5 is fixedly installed with a fan blade 6, and the pipe body The right side of 1 is fixedly installed with two buckles 7, and the bottom of the installation cylinder 4 is connected with an air outlet pipe 8 that is engaged with the buckle 7, and the end of the air outlet pipe 8 away from the installation cylinder 4 is connected. There is a sleeve 9, and the right side of the pipe body 1 is fixedly installed wi...

Embodiment 2

[0017] Embodiment 2: as figure 1 and figure 2 As shown, a coal-fired unit boiler sampling device in a thermal power plant includes a pipe body 1, the bottom of the pipe body 1 is fixedly installed with a suction cup 2 that penetrates and extends to the inside of the pipe body 1, and the top of the pipe body 1 is fixedly installed with a handle 3. The left side of the body 1 is fixedly installed with an installation cylinder 4, the inside of the installation cylinder 4 is fixedly installed with a motor 5, the output shaft of the motor 5 is fixedly installed with a fan blade 6, and the right side of the pipe body 1 is fixedly installed with two Buckle 7, the bottom of installation cylinder 4 is communicated with outlet pipe 8 snapped with buckle 7, the top of installation cylinder 4 is provided with the through hole that is suitable for suction pipe 11, and the bottom of installation cylinder 4 is also provided with outlet pipe 8. The air pipe 8 is matched with the through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com