Blade root bolt position verifier

A blade root end and inspection device technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve problems affecting the installation position of bolts and nuts, improve blade quality, increase effect, and facilitate inspection operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

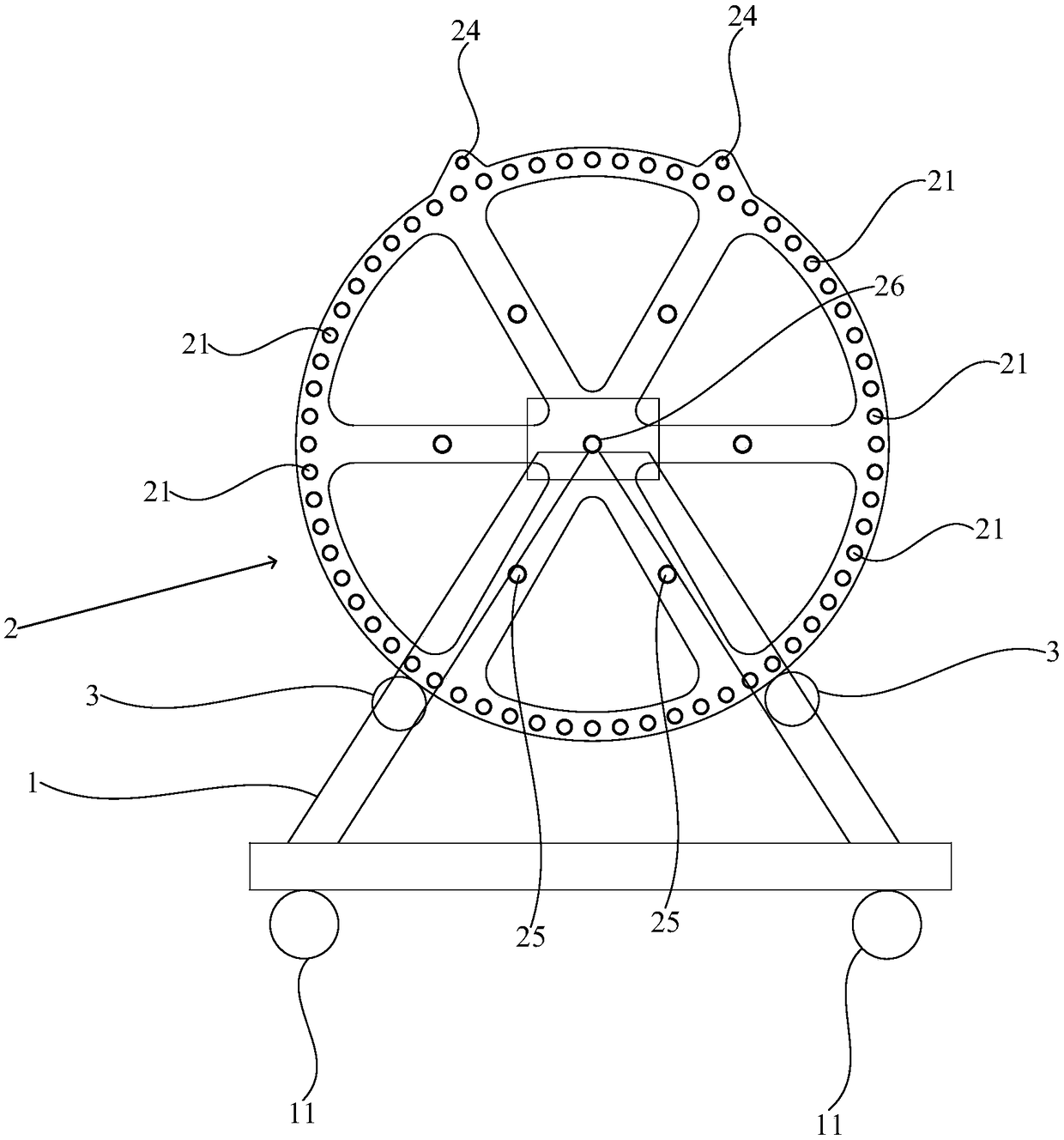

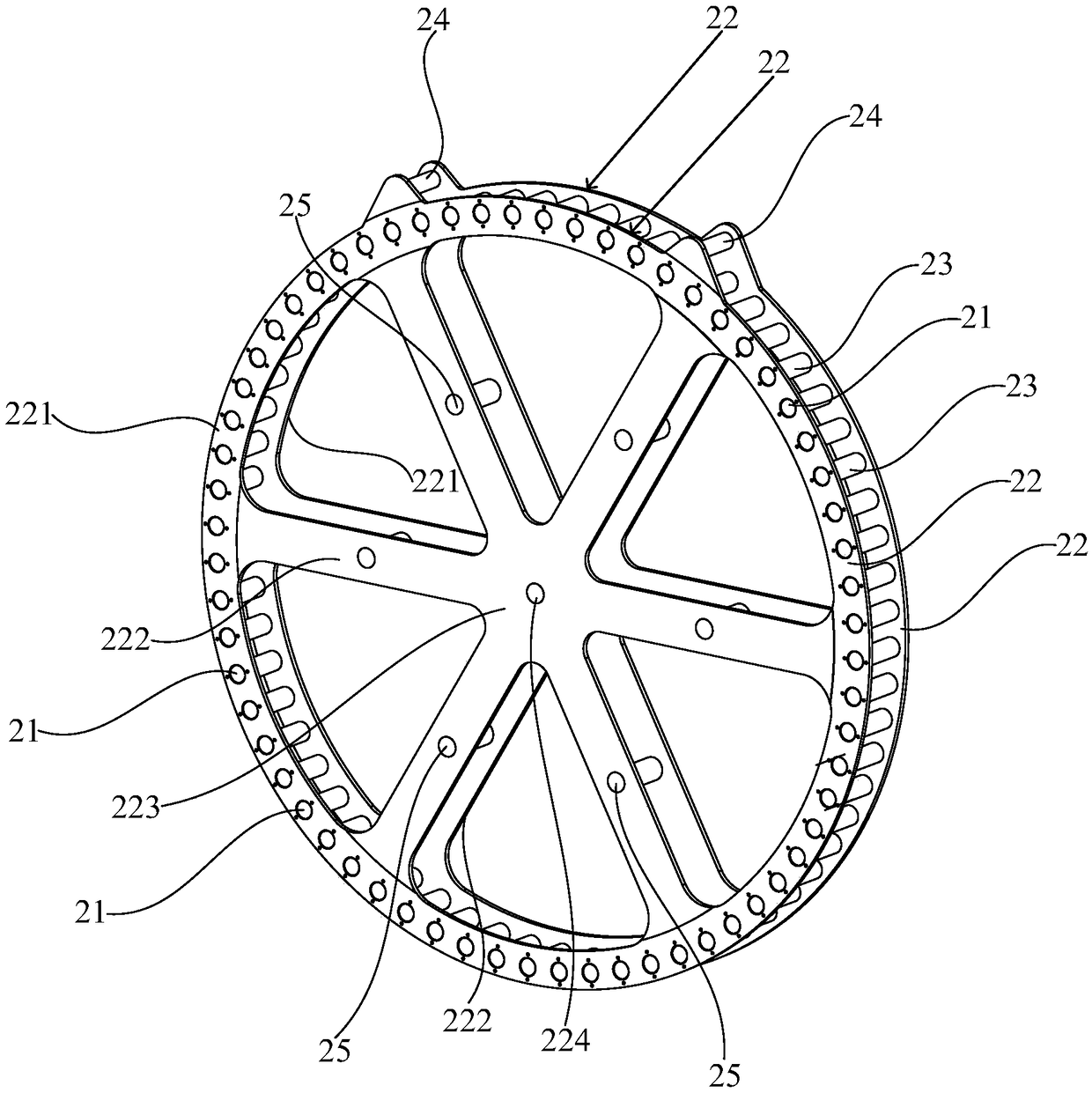

[0033] Such as figure 1 and figure 2 As shown, this embodiment discloses a blade root end bolt position inspection device, the blade root end bolt position inspection device includes a mounting frame 1 and a detection flange 2, the detection flange 2 is rotatably connected to the mounting frame 1, The detection flange 2 has several detection holes 21 , and the several detection holes 21 are located on the outer edge of the detection flange 2 and penetrate through the detection flange 2 along the radial direction of the detection flange 2 . After the bolts are installed at the blade root end, when the blade root end bolt position inspection device is inspecting the blade root end bolt position, the blade is lifted to a suitable height with a sling, and the blade root end bolt position inspection dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com