multi-hole fluid connector

A connector and fluid technology, applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of high cost, bulky, complex structure, etc., achieve light weight, small volume, locking method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

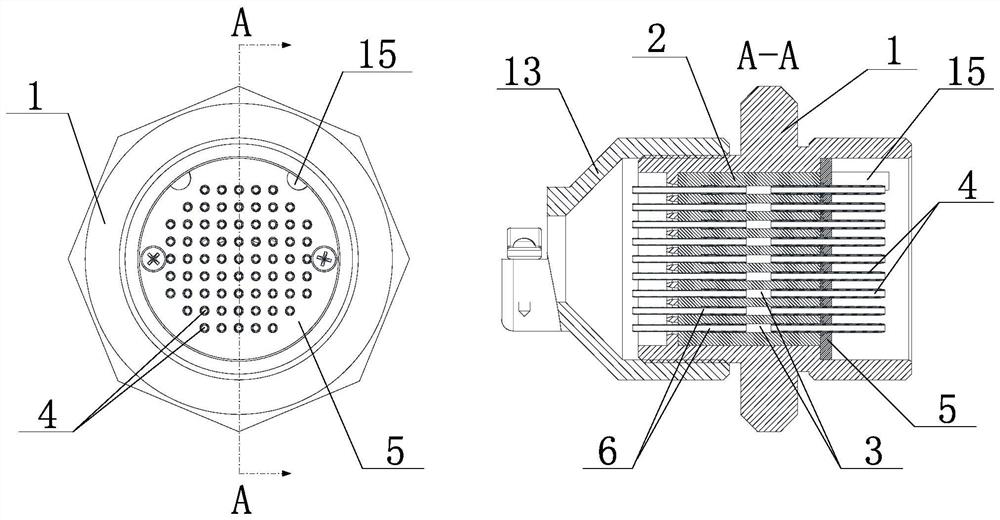

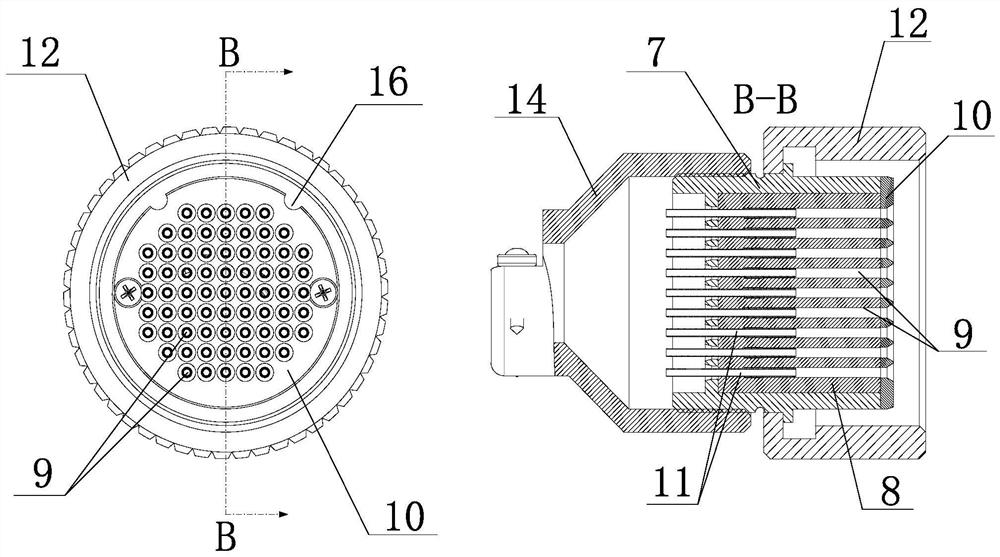

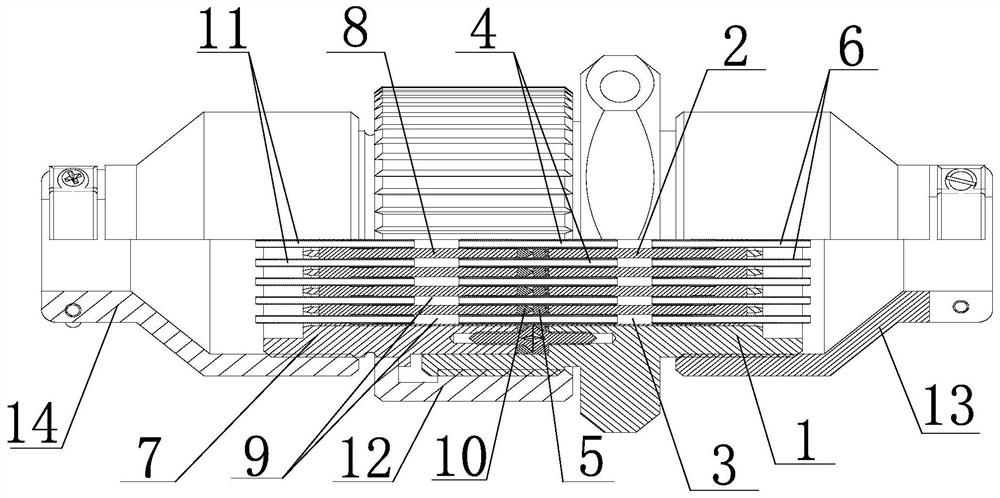

[0029] Such as figure 1 , figure 2 and image 3 As shown, the porous fluid connector of the present invention includes a male end connector and a female end connector, and is characterized in that the male end connector includes a porous connection male end housing 1, and the porous connection male end housing 1 is sleeved There is a public-end porous sealing body 2, and a plurality of public-end dense channels 3 arranged in parallel and running through both ends of the male-end porous sealing body 2 are arranged in the male-end porous sealing body 2, and one end of the male-end porous sealing body 2 is provided with a male end The porous baffle 5, the male-end porous baffle 5 is provided with installation and positioning step holes corresponding to the male-end intensive channels 3 one-to-one, and the end of the male-end dense channel 3 where the male-end porous baffle 5 is located is inserted with a connecting pin 4 , the other end is inserted with a male end capillary co...

Embodiment 2

[0032] Such as figure 2 As shown, the porous fluid connector of the present invention, on the basis of Embodiment 1, is provided with an external thread on the outer wall of the porous connection male end housing, and a connecting nut 12 is provided on the outer movable sleeve of the porous connecting female end housing, and the inner wall of the connecting nut The thread cooperates with the external thread of the outer wall of the porous connection male end housing. When the male end connector and the female end connector are mated and connected, the connection lock is formed by tightening the connection nut and the external thread of the porous connection male end housing.

[0033] Preferably, the end where the male end capillary connection pin on the porous connection male end housing is connected to the male end wire harness 13, and the end where the female end capillary tube connection needle on the porous connection female end housing is connected to the female end wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com