Space twisting plastic impeller type well submersible pump

A space-distorted, impeller-type technology, applied to non-variable pumps, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as the flow channel is not smooth enough, easy to leak, and the head is not enough , to achieve a smooth flow path, prevent leakage, and improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

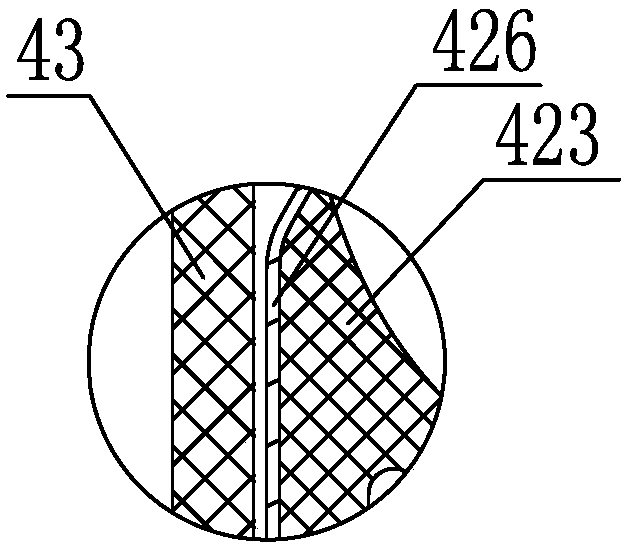

[0032] Depend on Figure 1-22 As shown, the embodiment of the space-distorted plastic impeller type well submersible pump of the present invention is: a casing 1 and a water outlet pump head 2, a check valve 3, a bearing seat 7, a sliding bearing 5, an adjusting Ring 6, multi-stage impeller assembly 4, coupling 8, water inlet base 9, and wire slot 10 installed on the outer surface of the housing. The multi-stage impeller assembly 4 includes a hexagonal pump shaft 41 and a multi-stage stack from top to bottom The guide vane wheel 42, the shaft sleeve 43, the impeller 44, the guide shell 45 and the pump shaft support frame 46 distributed at intervals are installed therein. The guide vane wheel 42 and the impeller 44 are all injection molded welded parts. Figures 9 to 13 As shown, the vane wheel 42 is welded by the vane seat 421 and the shroud 422, by Figures 18-21 As shown, the impeller 44 is welded by the main impeller 441 and the front cover plate 442 of the impeller. Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com