One-way prefabricated hollow slab with gradient cross section for composite slab of set block building

A technology of hollow slabs and laminated slabs, which is applied in construction, building materials, building components, etc., can solve the problems of large amount of cast-in-place concrete laminated layers and unreasonable force, and achieve saving concrete consumption, increasing sound insulation, The effect of reducing the positive bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

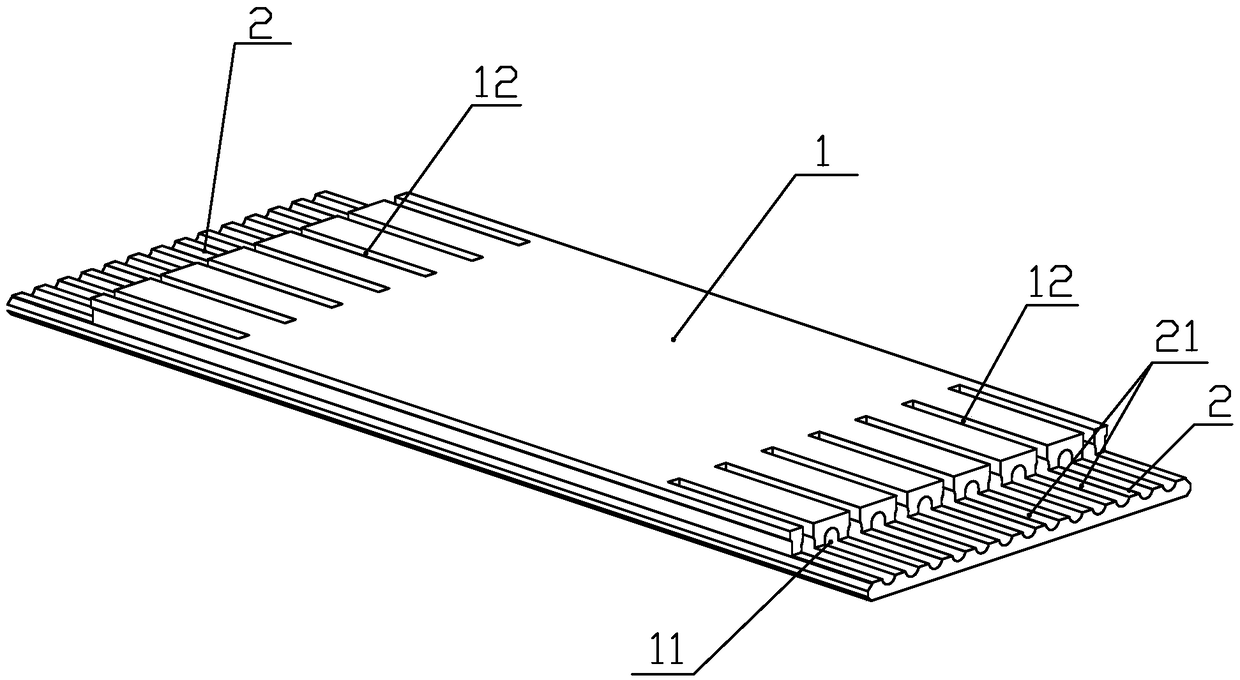

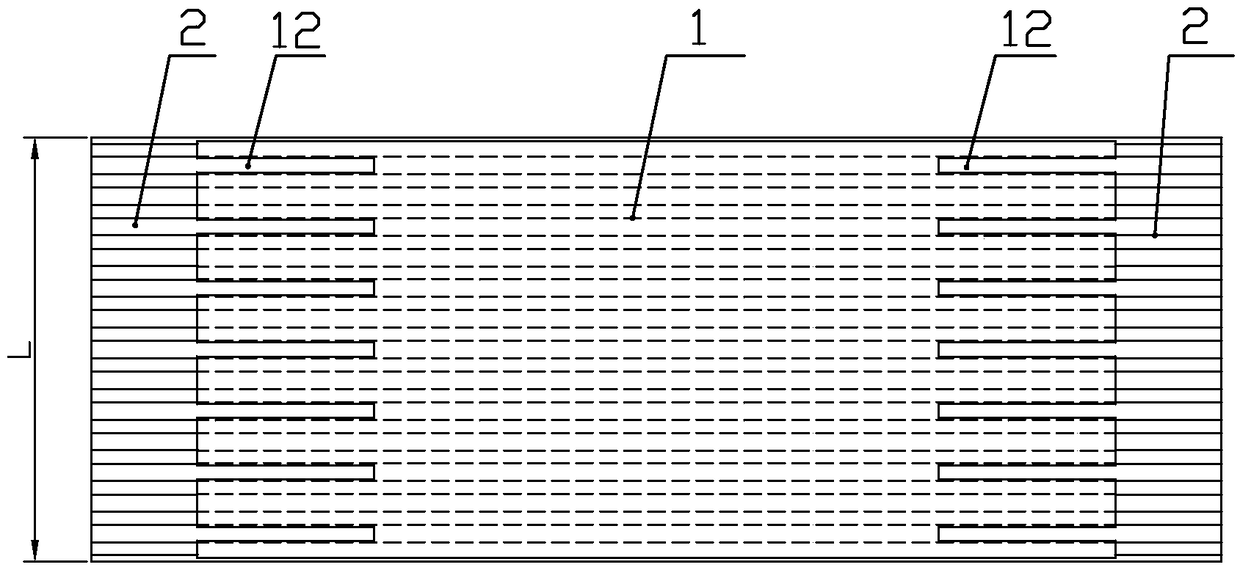

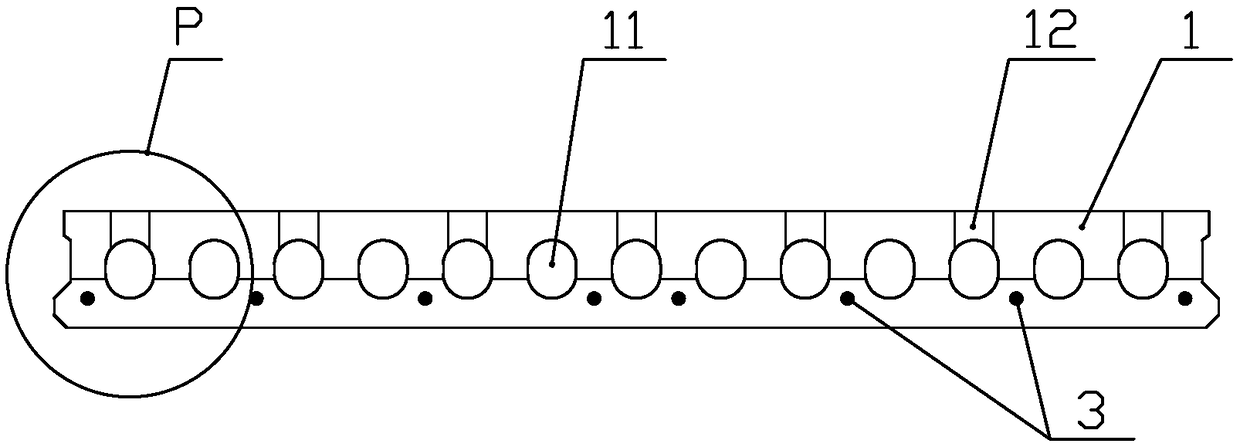

[0025] Specific implementation mode one: combine Figure 1~4 Describe this embodiment, a kind of tapered cross-section unidirectional prefabricated hollow slab for aggregate building laminated slabs, which includes a mid-span area 1 and support areas 2 located at both ends of the mid-span area 1, the bottom surface of the mid-span area 1 and the support area The bottom surface of 2 is located on the same horizontal plane, and the thickness of the support area 2 is smaller than the thickness of the mid-span area 1, and the mid-span area 1 of the hollow plate is processed with a number of through holes 11 along the span direction, and several through holes 11 are connected to each other along the horizontal direction. Arranged in parallel, the top surface of each support area 2 is provided with a number of first through grooves 21 along the span direction of the mid-span area 1, and the number of the number of the first through grooves 21 is the same as that of the number of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com