Double-wet-joint segment prefabricated bridge assembling linear adjusting device

A technology for adjusting devices and segmental beams, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems affecting the durability of joints, accidents, and displacement of bridge erecting machines, etc., to achieve splicing error control Difficult, linear speed, guaranteed precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

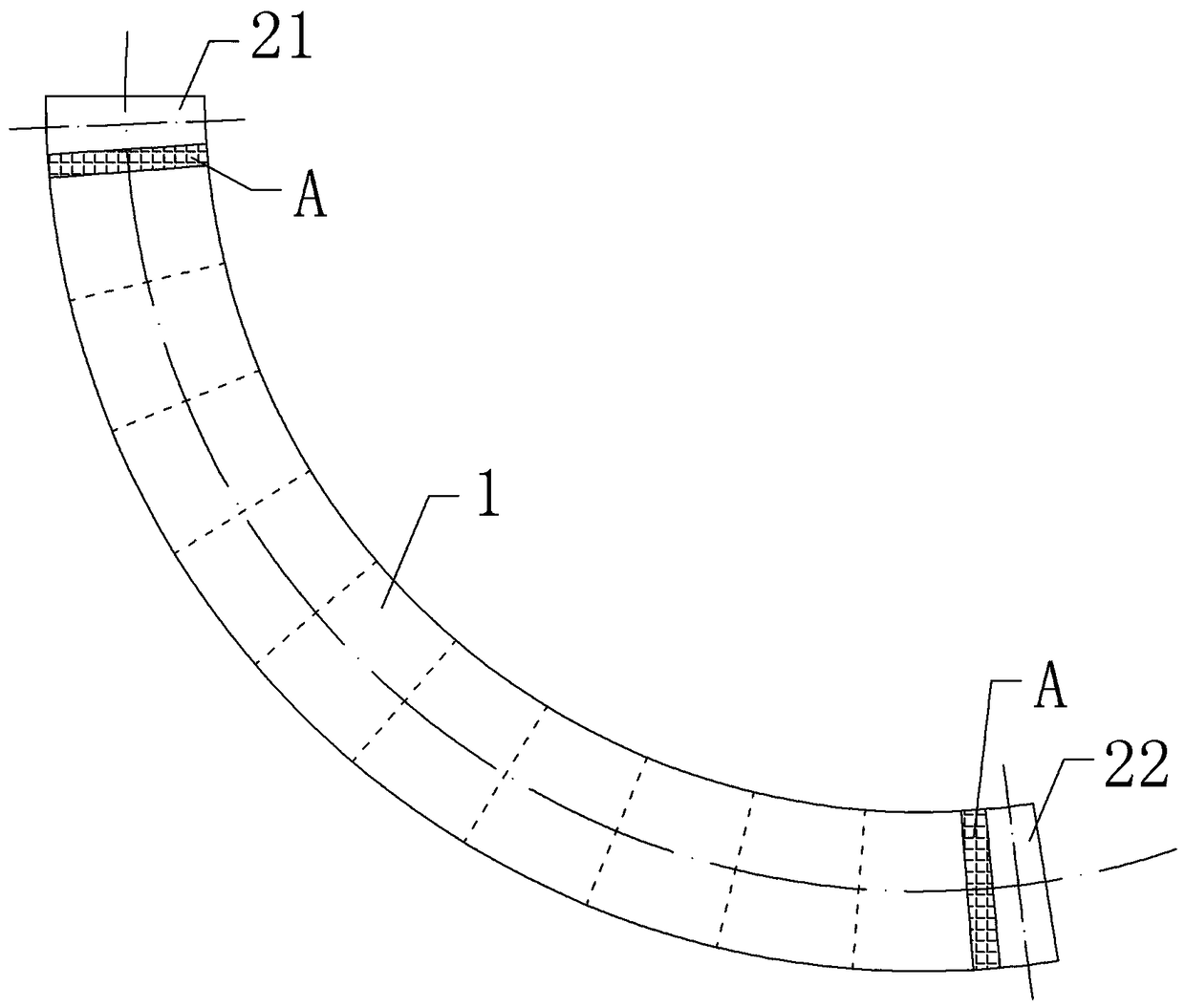

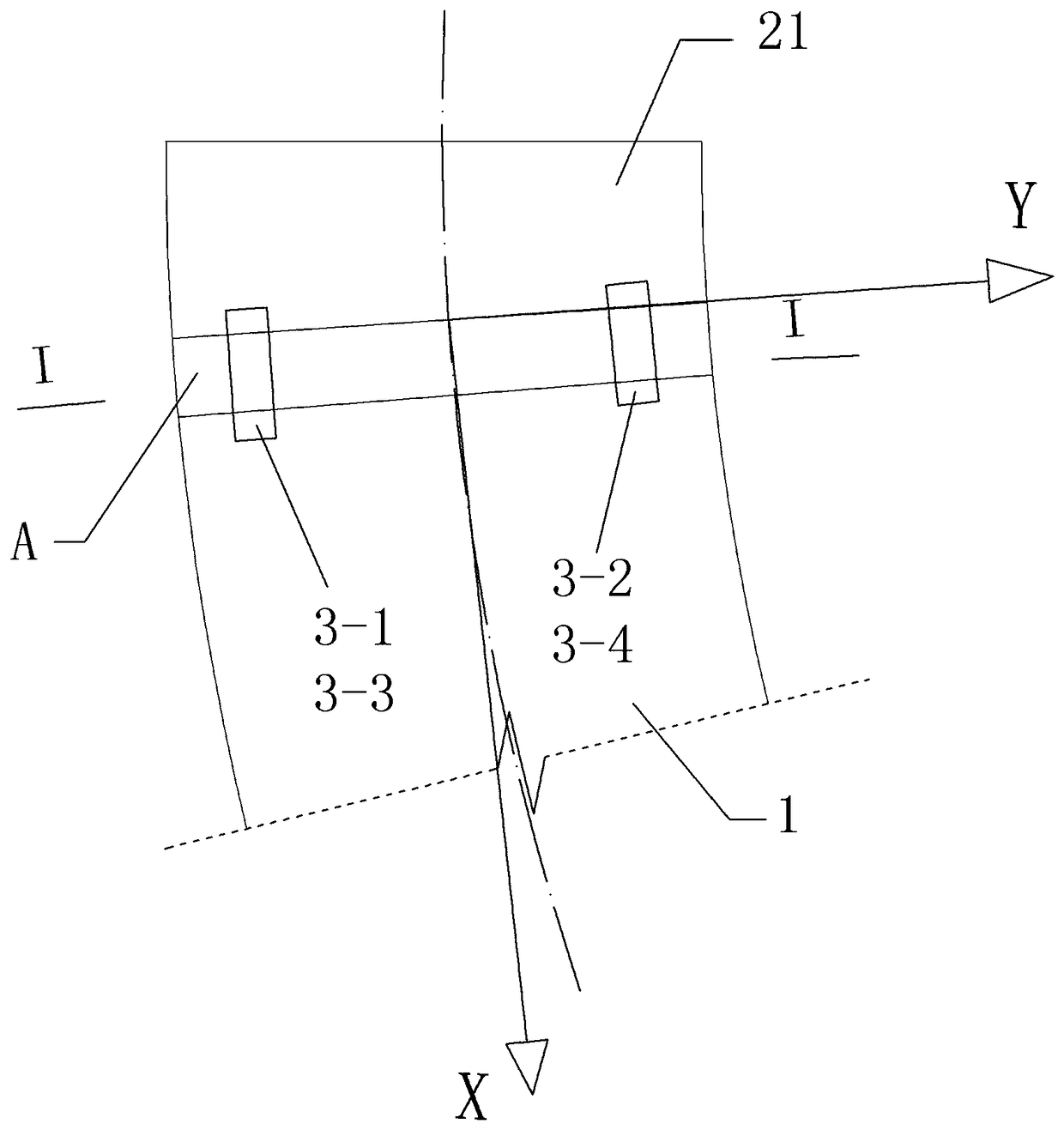

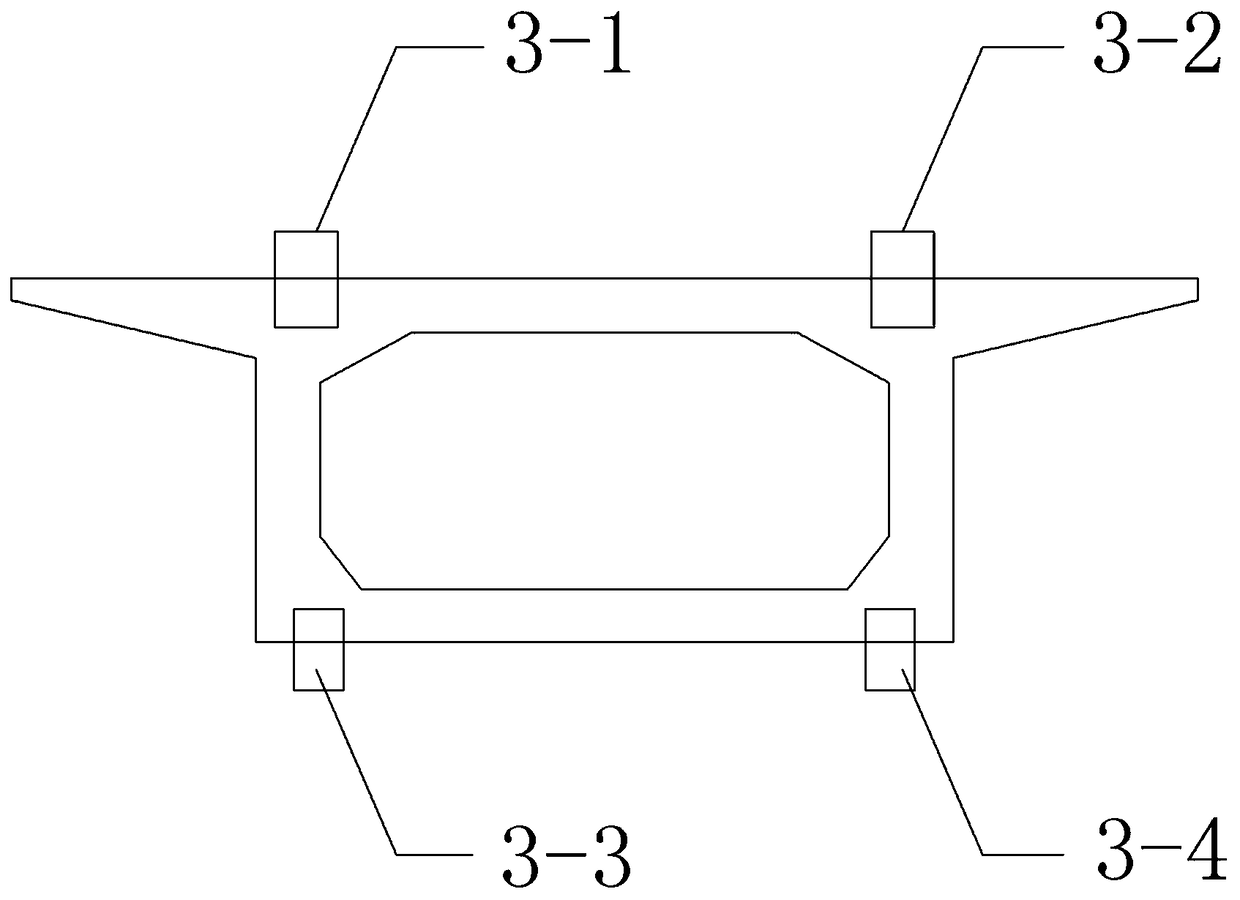

[0035] figure 1 It shows a segmental prefabricated bridge with double wet joints. This embodiment is aimed at the adjustment device for segment beam assembly alignment of the double wet joint prefabricated bridge, which is used for prefabricated segmental beams and pier top segments to be assembled. The linear adjustment of the assembly between the beams, the pier top segment beams at both ends of the prefabricated segment beam 1 to be assembled are respectively the first pier top segment beam 21 and the second pier top segment beam 22, as Figures 2 to 5 As shown, the assembly alignment adjustment device includes a plurality of telescopic actuators 3 arranged at the junction of the prefabricated segmental beam 1 to be assembled and the first pier top segmental beam 21, a power system 4 electrically connected to each telescopic actuator 3, A data analysis system 5 connected to the power system 4 and a measurement system 6 connected to the data analysis system 5, a plurality of...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that the prefabricated segmental beam to be assembled and the segmental beam at the top of the pier are T-shaped beams, and the number of telescopic actuators is two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com