A kind of rapid cooling equipment for hot-dip galvanizing

A rapid cooling, hot-dip galvanizing technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of color difference of metal parts, inability to cool metal parts, affecting the beauty of metal parts, etc., to achieve cooling Faster process, faster flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

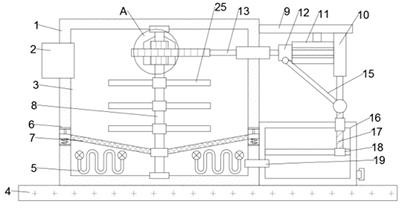

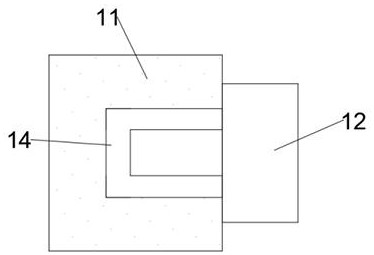

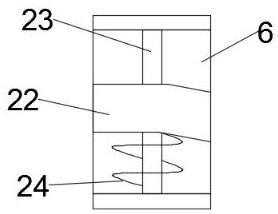

[0021] Depend on Figure 1~4 As shown, in the embodiment of the present invention, a kind of rapid cooling equipment for hot-dip galvanizing operation includes a housing 1, a material inlet 2, a cooling chamber 3 and a horizontal guide rail 11, the lower part of the housing 1 is provided with a base 4, and the housing The body 1 is fixed on the base 4, the top of the left side wall of the casing 1 is provided with a material inlet 2, and a cooling cavity 3 is arranged inside the casing 1, the material inlet 2 communicates with the cooling cavity 3, and the top of the right side wall of the casing 1 is fixed Install the horizontal connecting cross bar 9, the horizontal guide rail 11 is arranged below the horizontal connecting cross bar 9, the horizontal guide rail 11 and the horizontal connecting cross bar 9 are fixedly connected by bolts, the right end of the horizontal connecting cross bar 9 is provided with a hydraulic cylinder 10, and the hydraulic cylinder 10 The third con...

Embodiment 2

[0027] A metal surface treatment equipment, including the rapid cooling equipment for hot-dip galvanizing operation as described in embodiment 1.

[0028] In summary, the working principle of the present invention is: when the metal piece needs to be cooled, the metal piece is sent into the cooling chamber 3, and the hydraulic cylinder 10 is activated, and the hydraulic cylinder 10 can drive the third connecting rod 17 to move up and down, so that The third connecting rod 17 pulls the slider 12 to move left and right, and the slider 12 pulls the rack 21 to slide left and right, thereby realizing the rotation of the driving gear 20 and the rotating shaft 8, thereby realizing the mixing and stirring of the metal parts in the cooling chamber 3, which is beneficial to the cooling chamber 3. The metal parts are cooled quickly, and condensed water is introduced into the cooling pipe 5 at the same time. The up and down movement of the third connecting rod 17 can drive the piston plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com