Band steel cold rolling oil composition and preparation method thereof

A technology of cold rolling and oil composition, which is applied in the field of rolling oil, which can solve problems such as difficult maintenance, influence on lubricity and cleanliness, slow concentration response speed, etc., so as to reduce the difficulty of maintenance and management and improve the wide application , the effect of good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

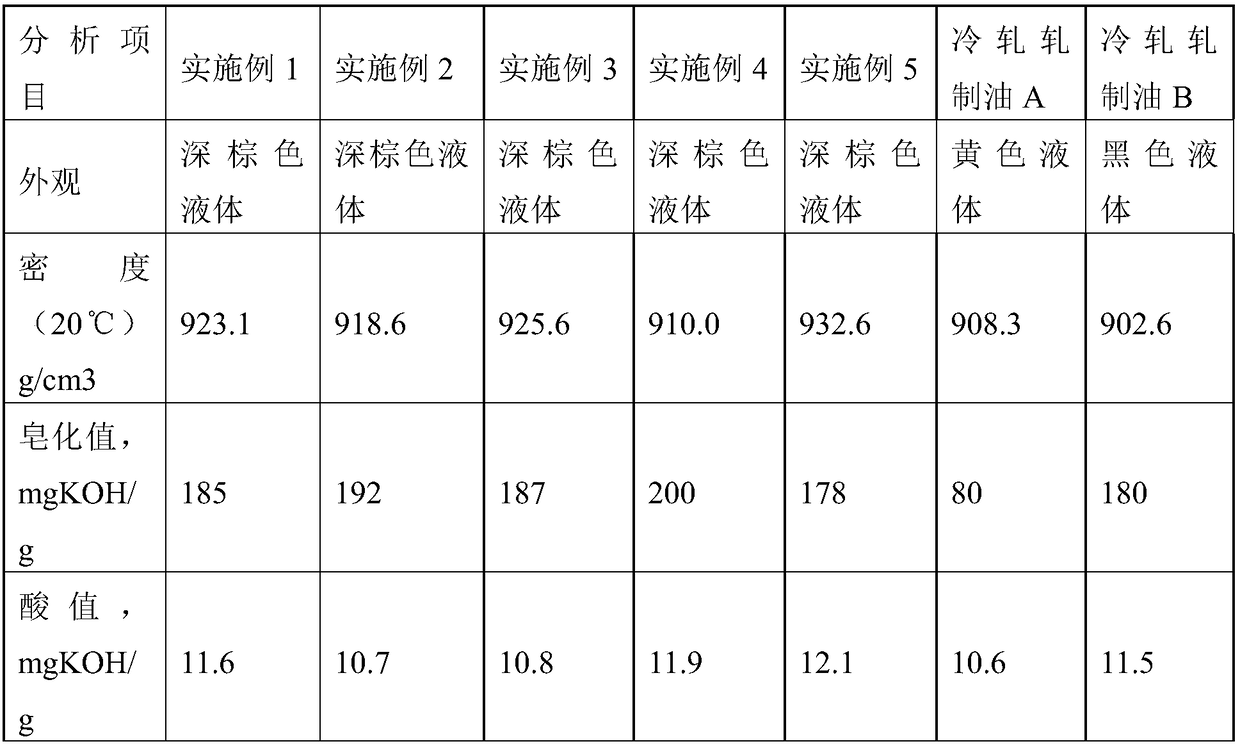

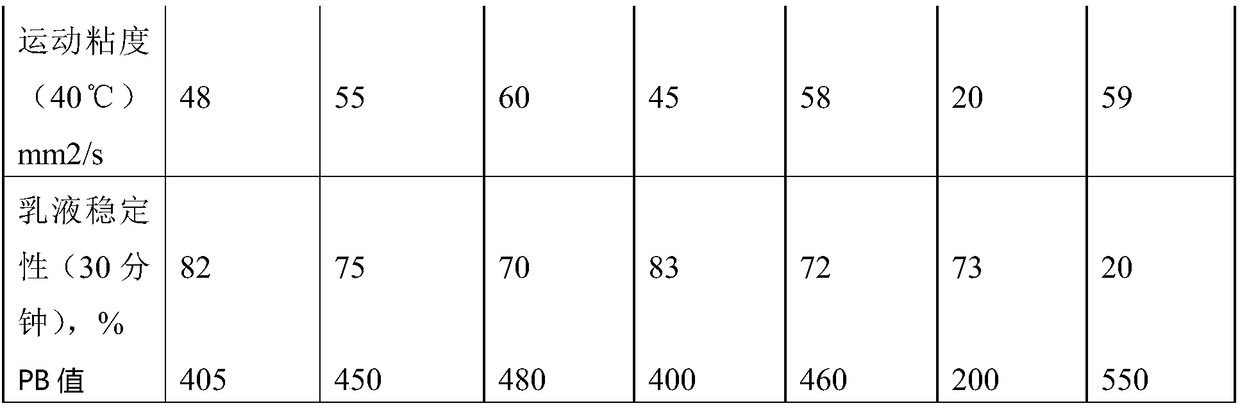

Examples

Embodiment 1

[0027] A kind of steel strip cold rolling rolling oil composition, comprises following composition according to mass percentage:

[0028] Trimethylolpropane Oleate 30%, Palm Oil 15%, Lard 15%, Mineral Oil 150SN 10%, Dioctyldiphenylamine 0.1%, Benzotriazole 0.5%, Sulfurized Lard 5%, Sulfurized Olefin 3%, 6721%, Doverlube NCL-21%, Hypermer A70 10% and GENAPOL X 0809.4%.

[0029] The preparation method of strip steel cold rolling rolling oil composition comprises the steps in the present embodiment:

[0030] 1) Weigh trimethylolpropane oleate, palm oil, lard, and mineral oil 150SN according to the above proportions and add them into the reaction tank, and heat to 80°C while stirring;

[0031] 2) Dioctyldiphenylamine and benzotriazole were weighed according to the above ratio and added to the mixture in step 1, keeping the temperature in step 1 at 80°C, and stirring until the solids were completely dissolved;

[0032] 3) cooling the mixture obtained in step 2 to a temperature ...

Embodiment 2

[0036] A kind of steel strip cold rolling rolling oil composition, comprises following composition according to mass percentage:

[0037] Trimethylolpropane Oleate 30%, Palm Oil 30%, Lard 20%, Mineral Oil 350SN 10%, Dioctyldiphenylamine 2%, Benzotriazole 4%, Sulfurized Lard 1%, Sulfurized Olefin 0.5%, 6720.5%, Doverlube NCL-20.5%, HypermerA701% and GENAPOLX 0801%.

[0038] The preparation method of strip steel cold rolling rolling oil composition comprises the steps in the present embodiment:

[0039] 1) Weigh trimethylolpropane oleate, palm oil, lard, and mineral oil 150SN according to the above proportions and add them to the reaction tank, and heat to 90°C while stirring;

[0040] 2) Dioctyldiphenylamine and benzotriazole were weighed according to the above ratio and added to the mixture in step 1, keeping the temperature in step 1 at 90°C, and stirring until the solids were completely dissolved;

[0041] 3) cooling the mixture obtained in step 2 to a temperature of 60°...

Embodiment 3

[0045] A kind of steel strip cold rolling rolling oil composition, comprises following composition according to mass percentage:

[0046] Trimethylolpropane Oleate 50%, Lard 20%, Mineral Oil 350SN 10%, Dioctyldiphenylamine 1%, Benzotriazole 2%, Sulfurized Lard 5%, Sulfurized Olefin 2%, 6721%, Doverlube NCL-21%, HypermerA 704% and GENAPOL X 0804%.

[0047] The preparation method of strip steel cold rolling rolling oil composition comprises the steps in the present embodiment:

[0048] 1) Weigh trimethylolpropane oleate, palm oil, lard, and mineral oil 150SN according to the above proportions and add them to the reaction tank, and heat to 85°C while stirring;

[0049] 2) Dioctyldiphenylamine and benzotriazole were weighed according to the above ratio and added to the mixture in step 1, keeping the temperature in step 1 at 85°C, and stirring until the solids were completely dissolved;

[0050] 3) cooling the mixture obtained in step 2 to a temperature of 55°C;

[0051] 4) Sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com