Parafoil platform and control method thereof

A platform and parafoil technology, applied in the field of parafoils, can solve the problems of reducing the reliability of the platform and occupying the available space inside the pod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

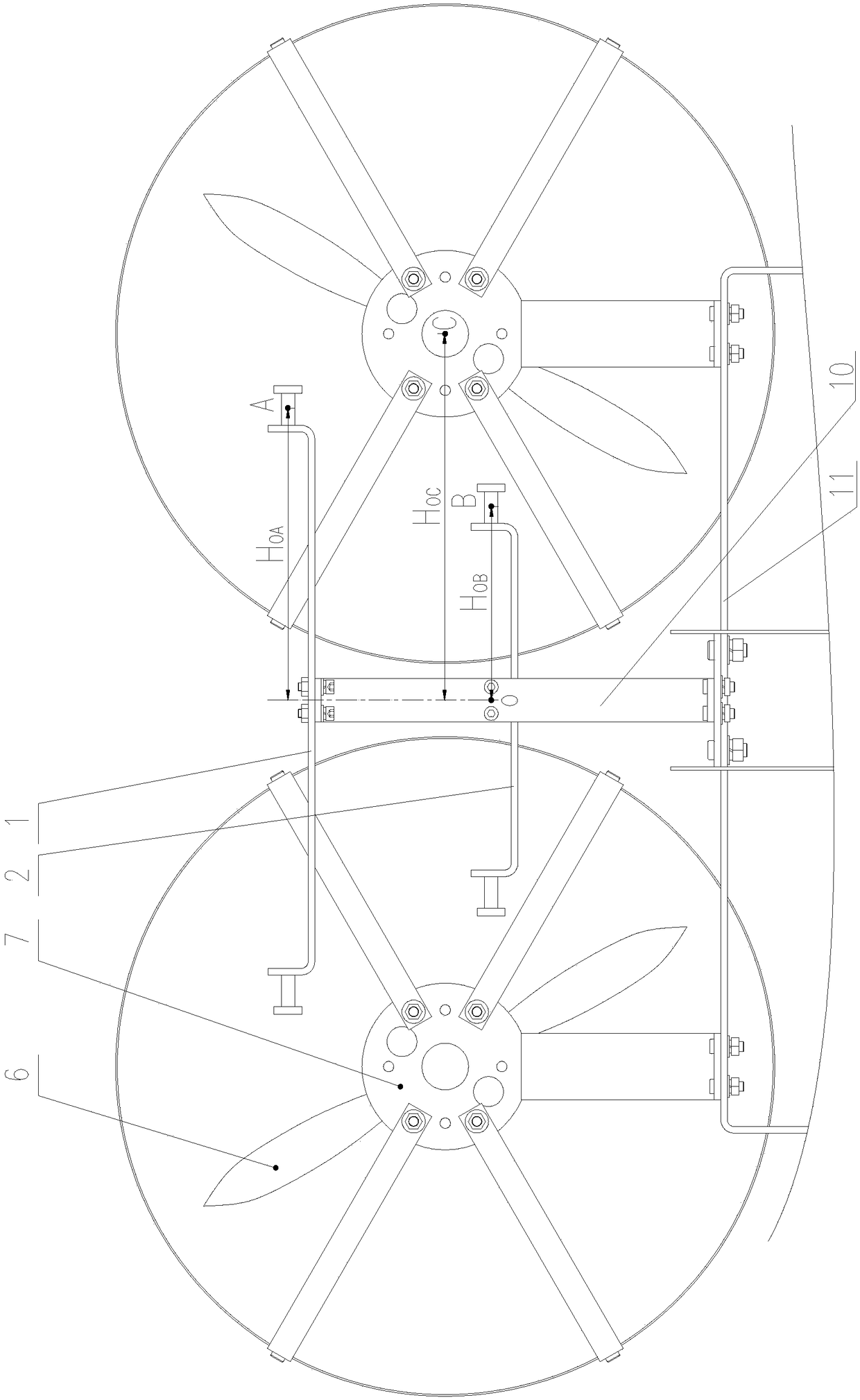

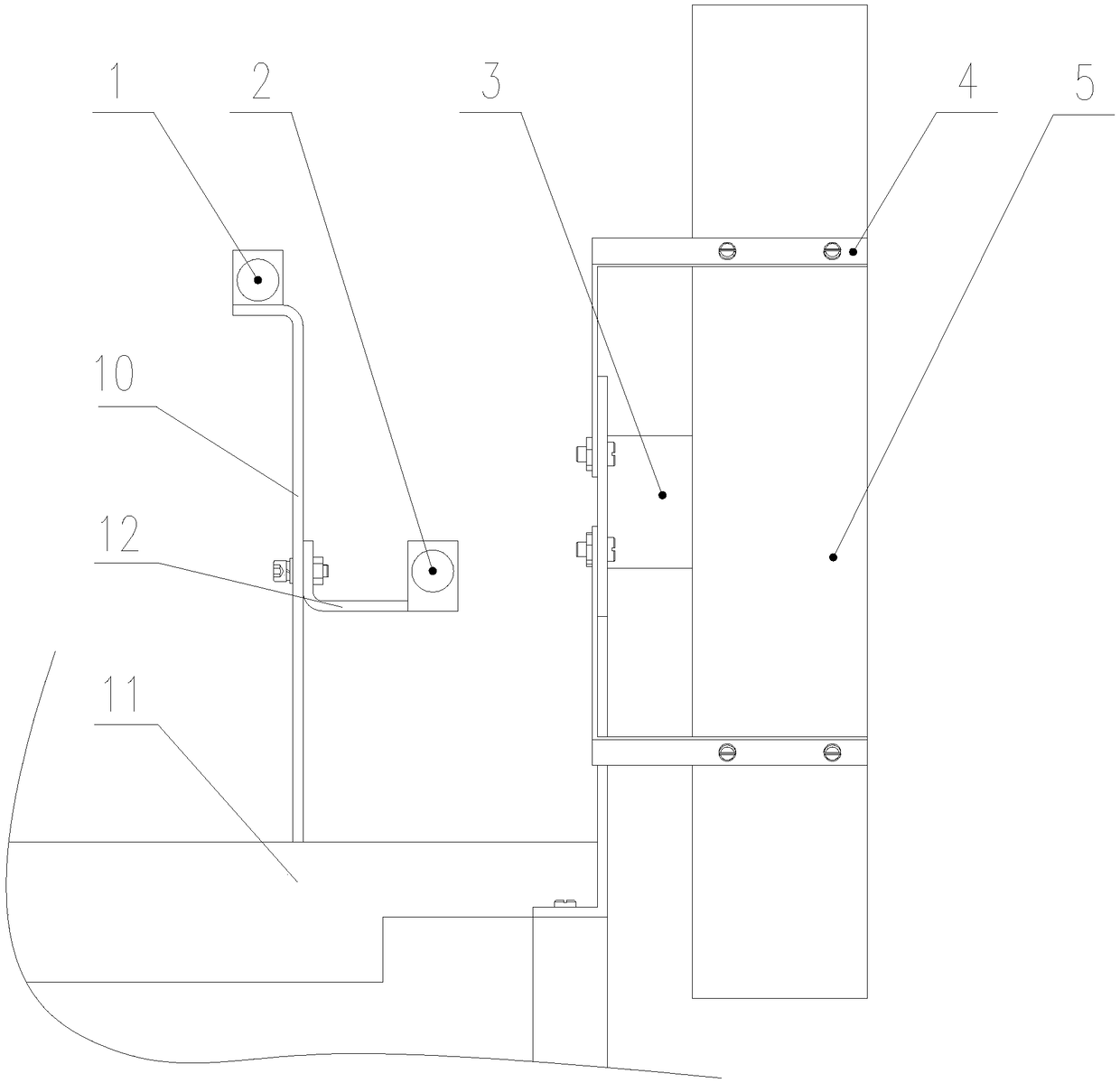

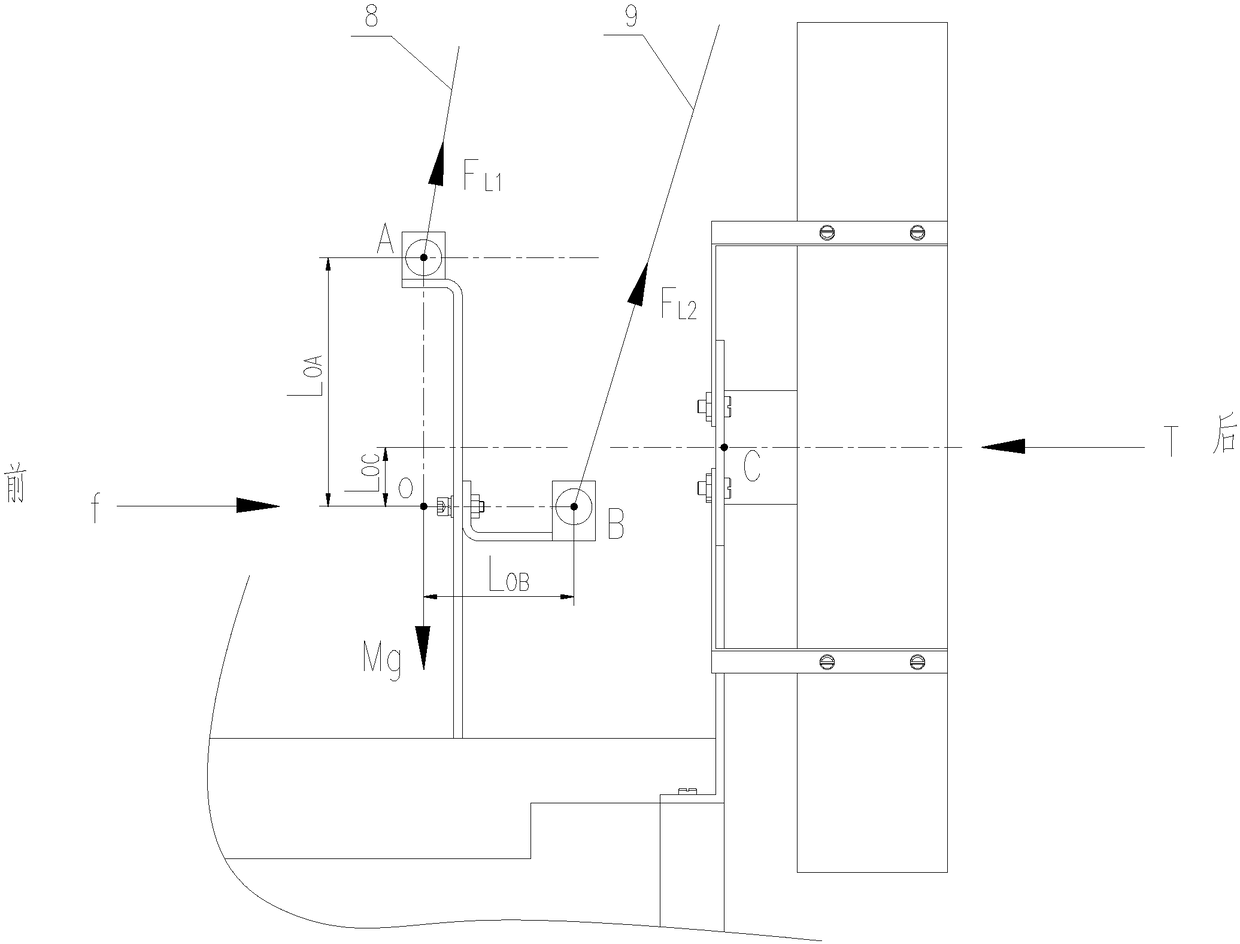

[0068] Example 1, such as figure 1 , figure 2 Shown:

[0069] The parafoil platform includes a parafoil, a pod platform 11, and two power units, each power unit is installed on the pod platform 11 through a connecting piece, the two power units are installed side by side, and the parafoil platform also includes;

[0070] Vertical bar 10; vertical bar 10 is installed on the upper part of pod platform 11, and vertical bar 10 is perpendicular to pod platform 11;

[0071] Suspension rod 1; the center of suspension rod 1 is connected with vertical rod 10 tops, and suspension rod 1 is parallel with gondola platform 11, and the two ends of suspension rod 1 are all connected with the suspension rope 8 of parafoil, and the upper ends of two suspension ropes 8 are all connected to each other. connected to the parafoil;

[0072] Cross bar 12; the first end of cross bar 12 is connected with the center of vertical bar 10, and cross bar 12 is vertical with suspension bar 1, vertical bar...

Embodiment 2

[0076] Example 2, such as figure 1 and figure 2 as shown,

[0077] The difference between this embodiment and Embodiment 1 is that the power unit includes:

[0078] Motor 3;

[0079] Propeller 6; the rotating shaft of motor 3 is fixedly connected with propeller 6 centers; the rotation plane of propeller 6 is parallel to vertical rod 10; the rotation plane of propeller 6 is perpendicular to pod platform 11; The projection center of the plane is the same as the distance from the centers of the propellers 6 of the two power devices; when the two propellers 6 are working, the directions of rotation are opposite;

[0080] Propeller cover 5; Propeller 6 is installed in the propeller cover 5;

[0081] Motor bracket 7; motor 3 is installed in the center of motor bracket 7, and motor bracket 7 is fixed on the connector; motor bracket 7 is externally connected with paddle cover 5 through multiple paddle bars 4.

[0082] The rotation direction of the two propellers 6 is opposite wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com