U-shaped arm for air suspension

An air suspension, U-shaped technology, applied in the direction of suspension, elastic suspension, cantilever installed on the pivot, etc., can solve the problems that cannot be satisfied, the connection strength cannot meet the requirements, affect the use, etc., to meet the load needs, the effect of ensuring the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

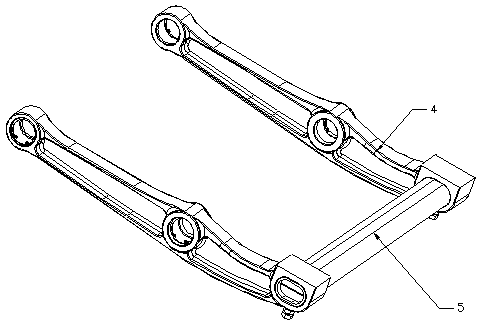

[0036] like figure 1 The shown air suspension includes a vehicle frame 1 , suspension brackets 3 are connected to both sides of the vehicle frame 1 , and U-shaped arms are arranged below the vehicle frame 1 .

[0037] The U-shaped arm is a U-shaped structure formed jointly by a pair of guide bracket arms 4 and a torsion connector 5 connecting the two guide bracket arms 4. One end of the guide bracket arms 4 is connected with the suspension bracket 3, and the guide bracket arms 4 The other end of the airbag 2 is connected with the vehicle frame 1, and one end of the guide arm 4 has a cavity A that just accommodates the end of the torsion connector 5, and the end of the torsion connector 5 that extends into the guide arm 4 has A cavity B 9 for accommodating the first fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com