Electronic crosslinking treatment device and film material electronic crosslinking treatment method

An electronic cross-linking and processing device technology is applied in the field of electronic cross-linking processing devices, which can solve the problems of low cross-linking density and scanning uniformity, complex structure and high cost of film processing, and ensure the cross-linking density and scanning uniformity. efficiency, improve production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

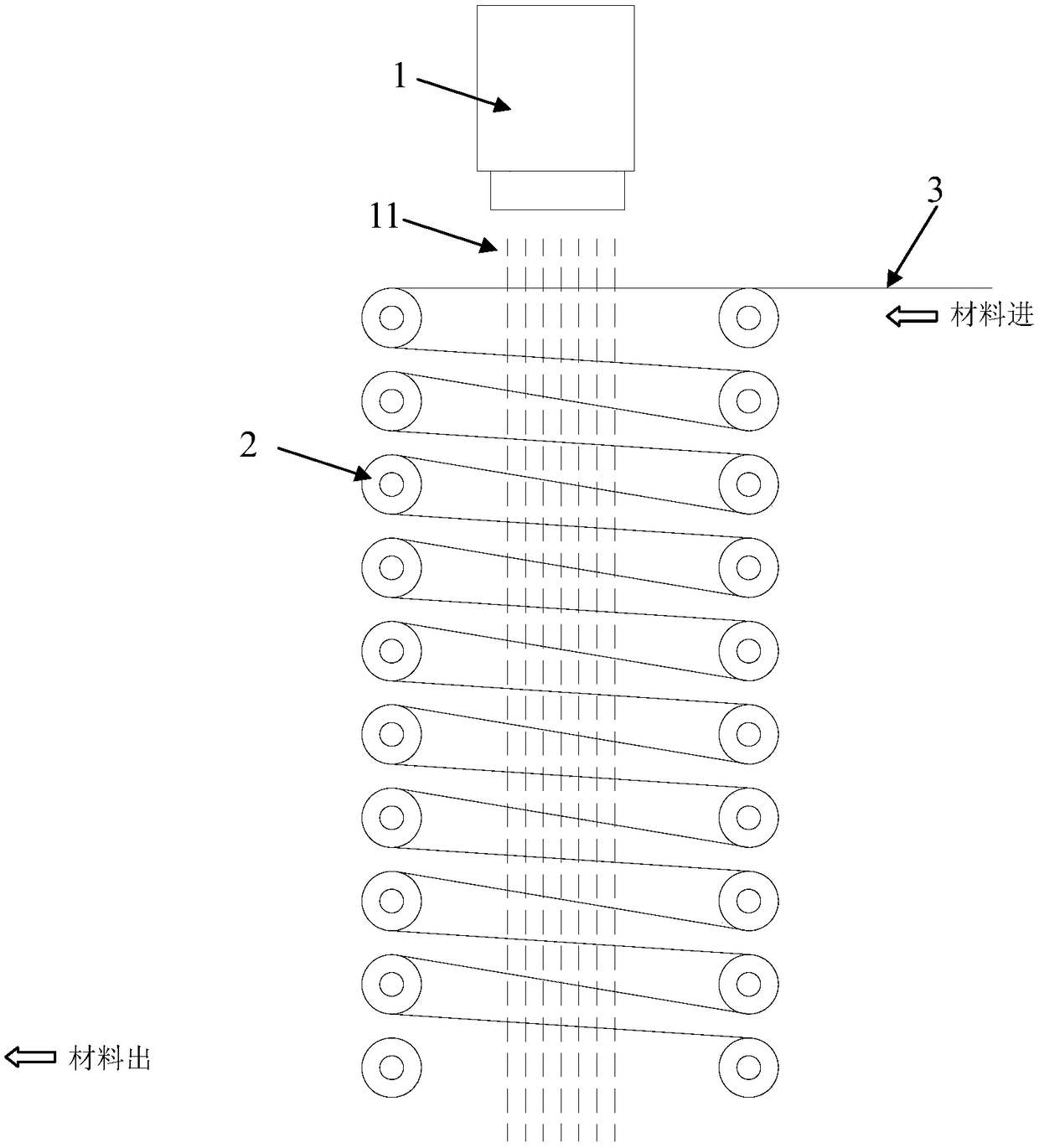

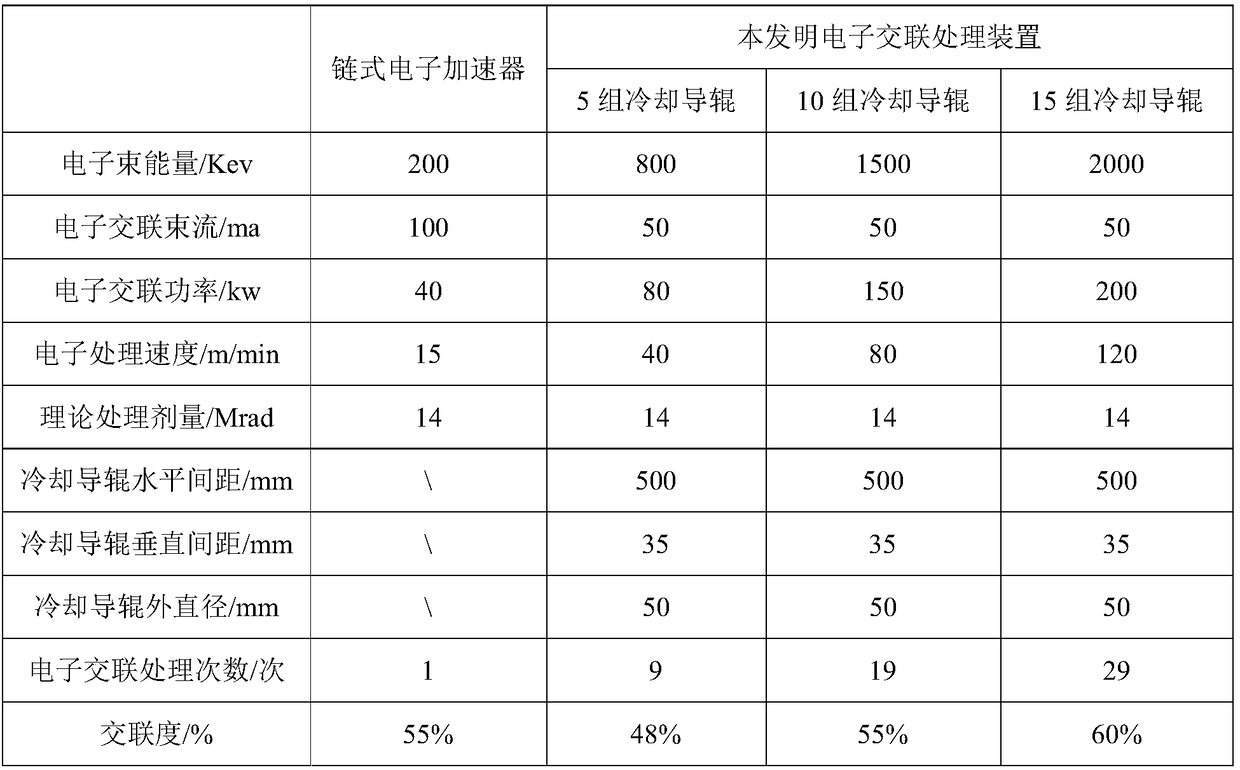

[0024] see figure 1 , a new type of electronic cross-linking processing device for membrane materials, which includes a scanning electron accelerator 1 and a transmission device 2. The electron beam 11 emitted by the scanning electron accelerator 1 has an energy of 800Kev~3Mev, and the penetration depth of the material with a density of about 1.0 It can reach 1.0mm ~ 3.5mm. The transmission device 2 is composed of several horizontally placed cooling guide rollers, and these cooling guide rollers are vertically distributed in two rows in groups of two, and are respectively located on both sides of the emission path of the electron beam 11 . Among them, the horizontal spacing of the cooling guide rollers is 30mm-1000mm, and the vertical spacing is 20mm-50mm; the material of the cooling guide rollers is stainless steel, the outer diameter is 35-70mm, and its length matches the width of the processing chamber and the maximum outlet film width. It is a middle-pass structure; cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com