Control method for mobile phone shell cleaning by using dry ice

A technology of dry ice cleaning and control methods, which is applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low efficiency and high cost, and achieve the effect of improving cleaning effect, wide application range and market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

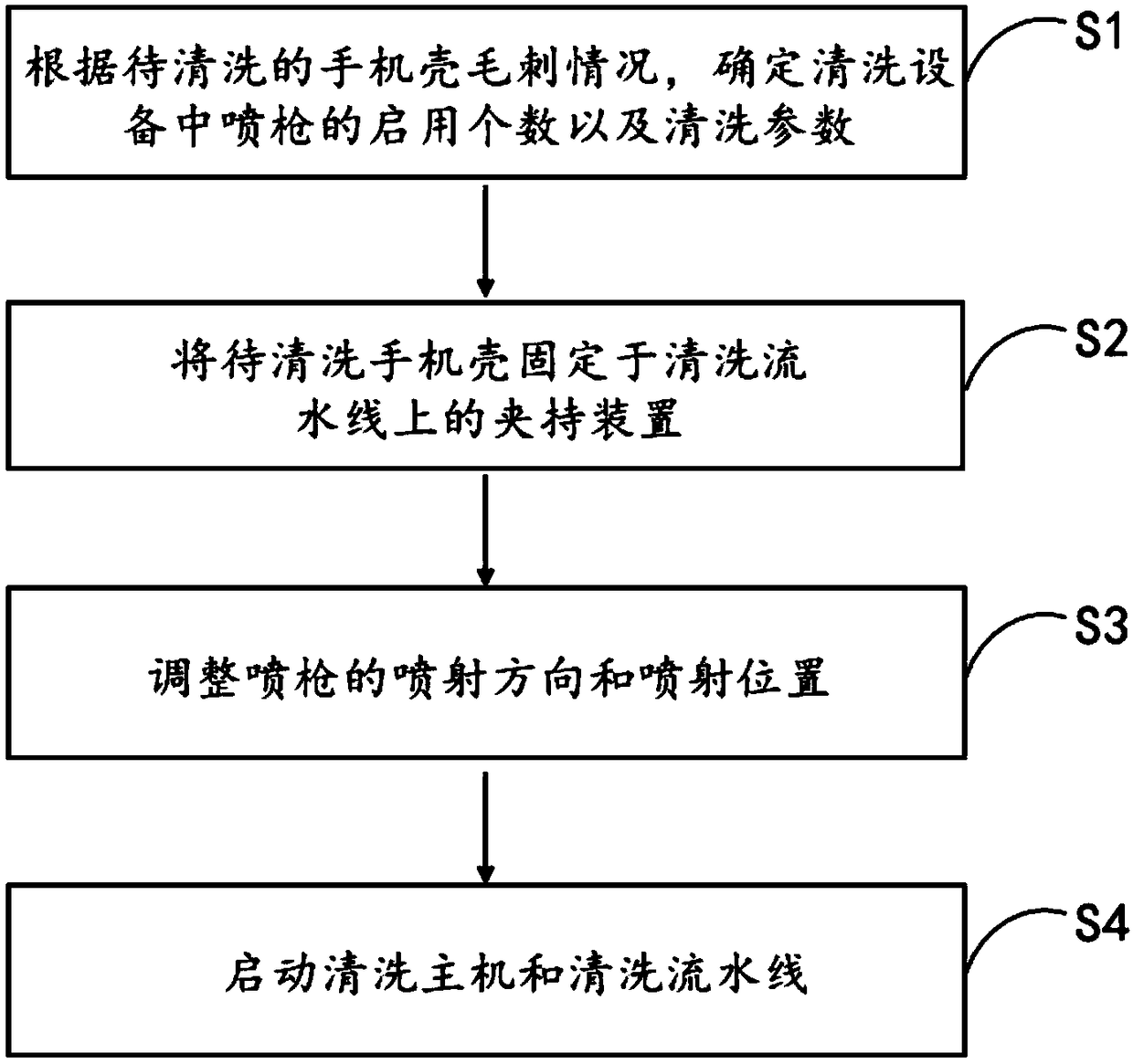

[0046] Embodiment 1, with reference to figure 1 As shown, the embodiment of the present invention provides a control method for dry ice cleaning mobile phone case, including the following steps:

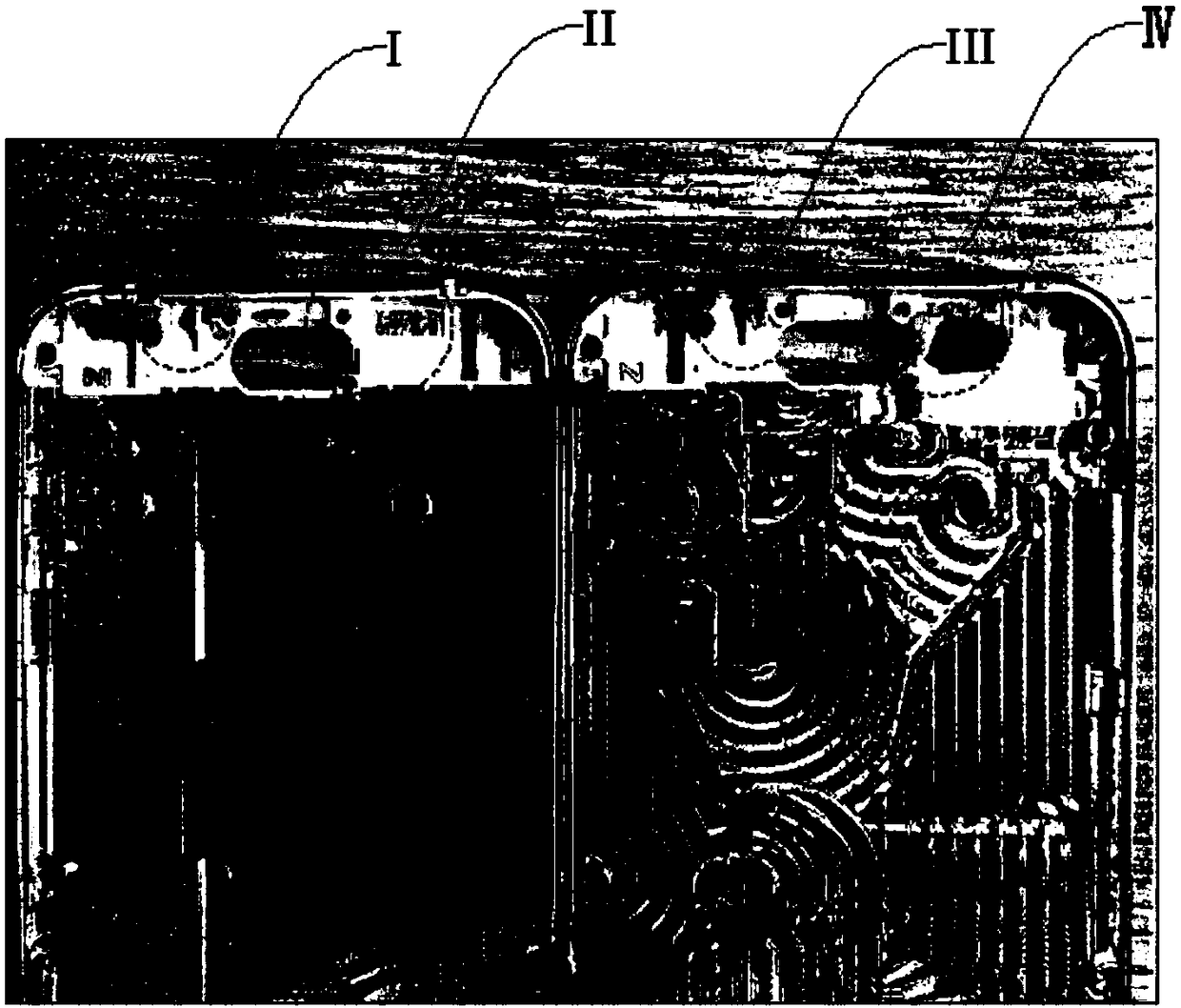

[0047] Step 1. Determine the number of spray guns and cleaning parameters in the cleaning equipment according to the burrs on the mobile phone case to be cleaned, wherein the cleaning equipment includes a cleaning assembly line and a cleaning host, and a cleaning device is arranged on the cleaning assembly line. The cleaning device is provided with a plurality of spray guns for spraying dry ice, and the cleaning host provides solid dry ice particles for the spray guns. Wherein, the mobile phone case is a mainstream mobile phone case of 5-7 inches in the market, and the material of the spray gun is stainless steel or alloy material.

[0048] Optionally, the cleaning host includes a hopper, an ice crushing device, and a mixing device. The dry ice enters the ice crushing device through...

Embodiment 2

[0068] The embodiment of the present invention provides a control method for dry ice cleaning mobile phone case, using the following dry ice cleaning machine:

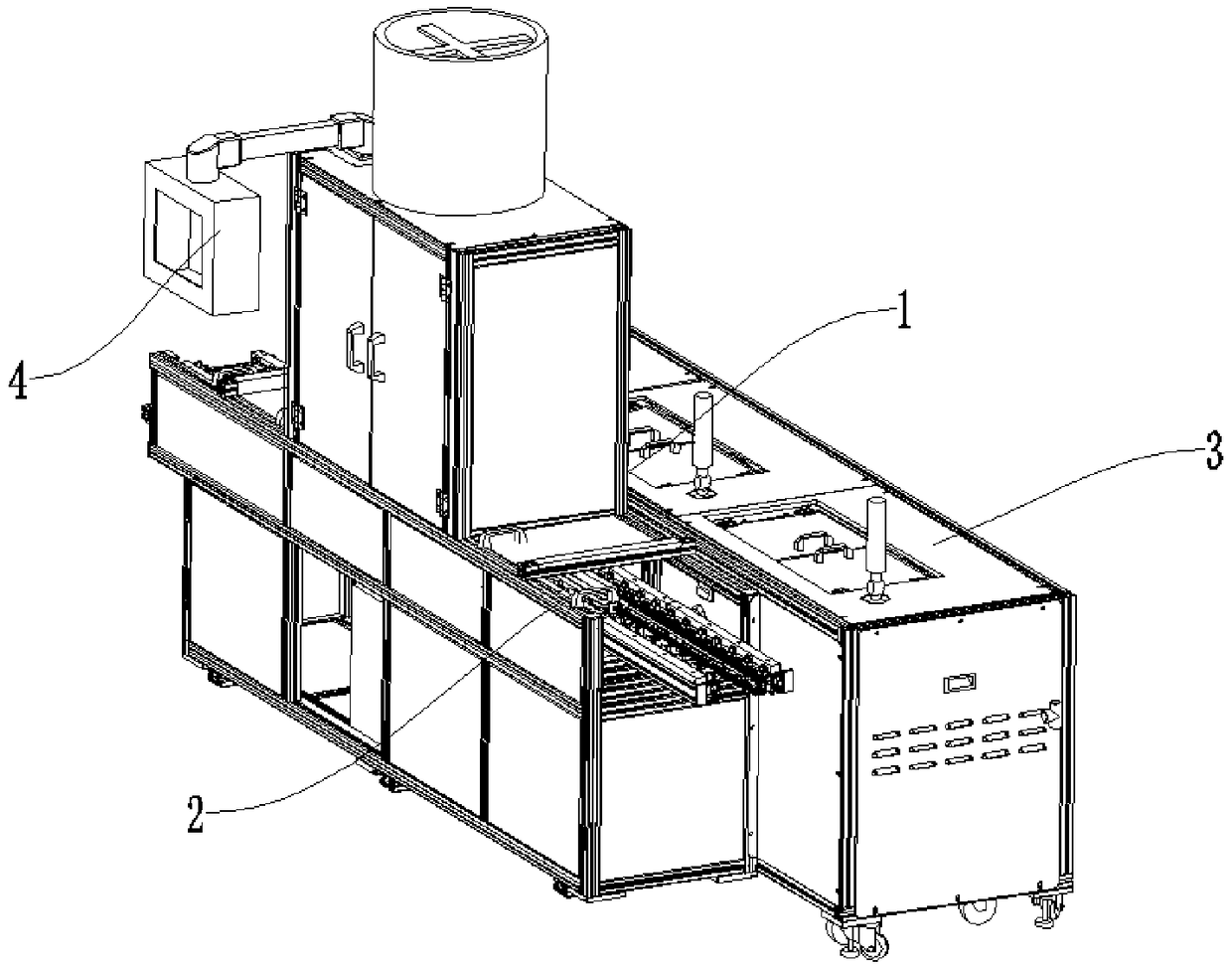

[0069] refer to image 3 , 4 As shown, this embodiment provides a dry ice blasting machine, including: a frame 1 , a cleaning line 2 , a cleaning host 3 and a controller 4 . By adopting an independent modular design, each module is independently installed at each position of the rack 1 and can be disassembled and replaced independently.

[0070] The frame 1 is used to provide a working chamber to support the dry ice blasting machine.

[0071] optional, see Figure 3-8 As shown, the frame 1 as a whole is constructed of aluminum alloy profiles, and has a plurality of cabinets made of stainless steel wire drawing sheet metal. The cleaning assembly line 2 and the cleaning host 3 are respectively installed in the cabinets. Modules are designed with disassembly handles and ventilation channels.

[0072] The cleaning lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com