Method for preparing high-nickel positive electrode material and high-nickel positive electrode material obtainable by the method

A positive electrode material, high nickel technology, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of long washing coating time, limited battery capacity of positive electrode materials, low temperature, etc., to achieve excellent capacitance and cycle performance, reduce The effect of residual lithium on the surface and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the preparation of the matrix according to step a) of the present invention, it is also possible to dope the matrix with other metals. As an example of other doped oxides, Al can be given 2 o 3 , ZrO 2 、TiO 2 , MgO, ZnO in one or more than two. The amount of other doping oxides can also be determined according to the required doping amount of other metals. In an embodiment of the present invention, the addition amount of other doping metal oxides is such that the amount of other doping metals is in the range of 100-2000 ppm relative to the total weight of the matrix.

[0037] In a specific embodiment according to the present invention, step a) is carried out as follows: first, feed the high-nickel ternary precursor, lithium hydroxide, boron-containing compounds and other doping oxides into the mixing device, and then add The mixing medium is mixed, the weight ratio of the total weight of the material to the mixing medium is 1: (0.5-2), and the mixing time is 0.5...

Embodiment

[0054] In order to facilitate understanding of the present invention, the present invention enumerates the following examples. Those skilled in the art should understand that the examples are only used to help understand the present invention, and should not be regarded as a specific limitation of the present invention.

[0055] testing method

[0056] Surface residual lithium test method:

[0057] Acid-base titration method: add 30g sample into 100ml pure water, stir for 30min, let it stand for 5min, filter with suction, take 10ml supernatant, and titrate the lithium carbonate dissolved from the positive electrode material with 0.05mol / L hydrochloric acid standard solution And lithium hydroxide, the pH electrode is used as the indicator electrode, and the end point is determined by means of the jump generated by the potential change, and the amount of residual lithium on the surface of the positive electrode material is calculated.

[0058] Initial gram capacity test method...

Embodiment 1

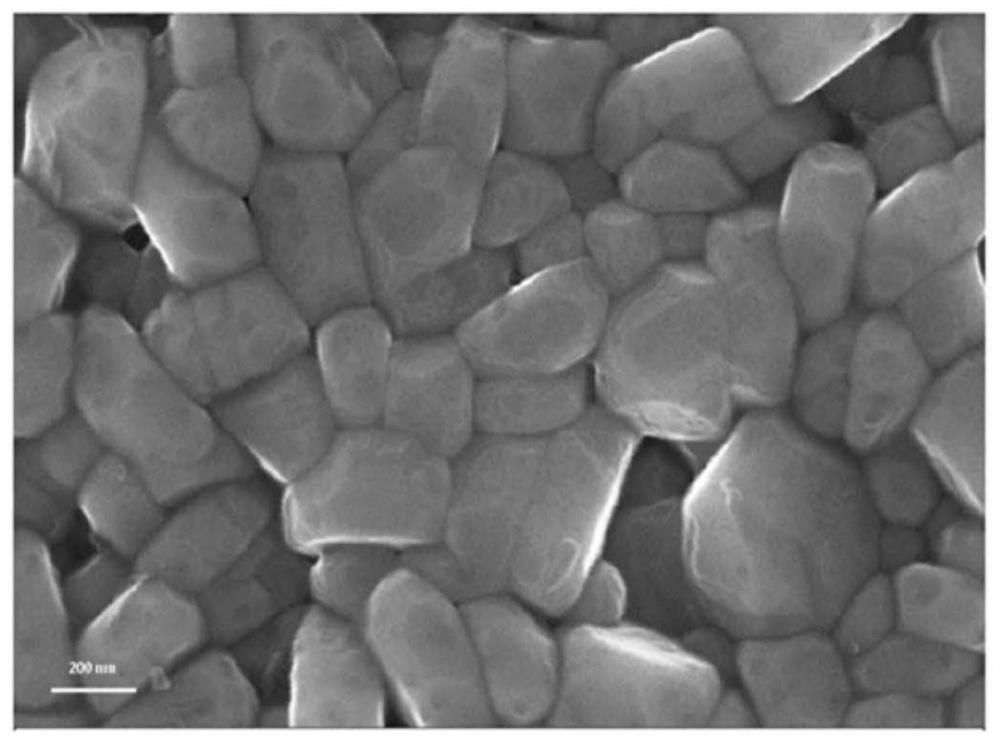

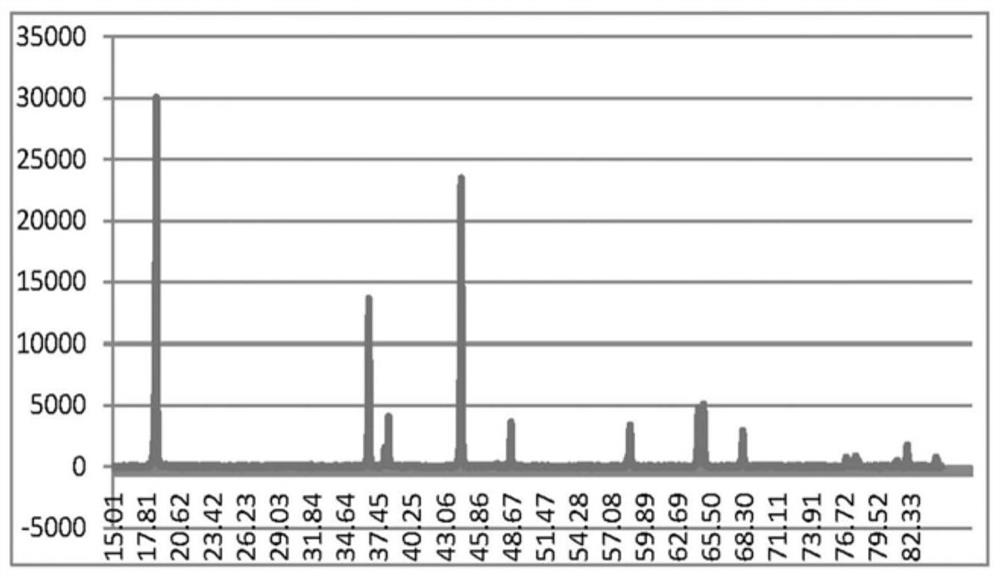

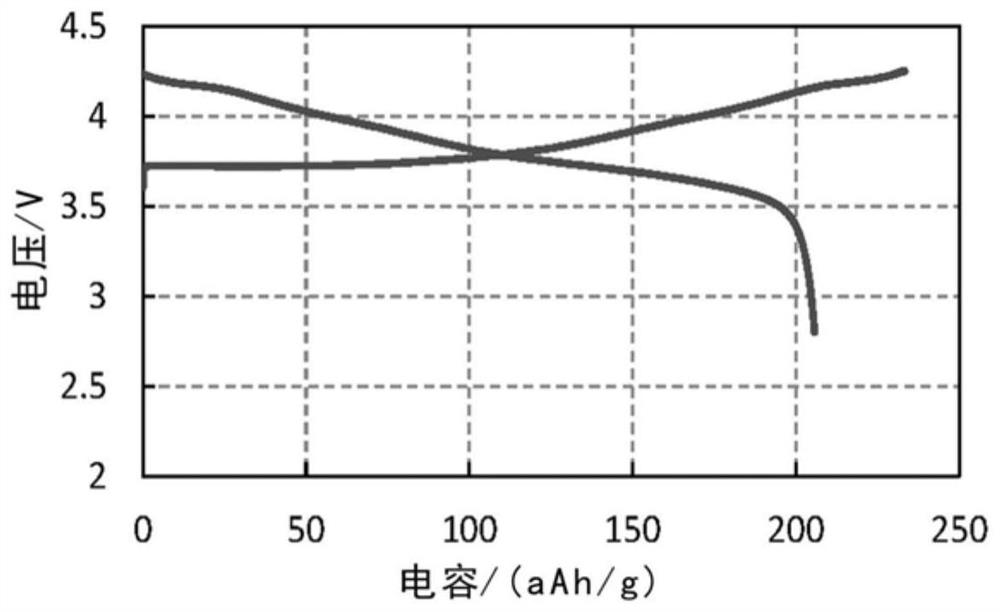

[0069] Add high nickel ternary precursor, lithium hydroxide, B 2 o 3 And zirconia to the oblique mixer, the molar ratio Li / Me of the ternary precursor and lithium hydroxide is 1.05, B 2 o 3 Add the amount so that the B content is 1000ppm, the weight ratio of the added zirconia is 0.2%, add polytetrafluoroethylene balls, the ratio of the total weight of the material to the weight of the polytetrafluoroethylene balls is 1:1, and the mixing time is 1h, and the initial Sintered materials, wherein: the high-nickel ternary precursor is [Ni 0.8 co 0.1 mn 0.1 ](OH) 2 . Put the prepared materials into the atmosphere roller furnace for sintering, the sintering temperature is 830°C, and the sintering atmosphere is O 2 , O 2 The concentration is 80%, the sintering time is 15h, and the high-nickel ternary positive electrode base material is obtained, and its initial capacity is 201mAh / g. Weigh a certain amount of H 3 BO 3 Add it to deionized water to make 1mol / L H 3 BO 3 solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com