Vegetable orderly harvesting machine

A harvester and vegetable technology, which is applied in the field of agricultural and forestry machinery, can solve the problems of vegetables being damaged, soil brought into the vegetables, and vegetables with roots cannot be harvested, so as to achieve outstanding substantive features, avoid hurting people and animals, and avoid stubble cutting. uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

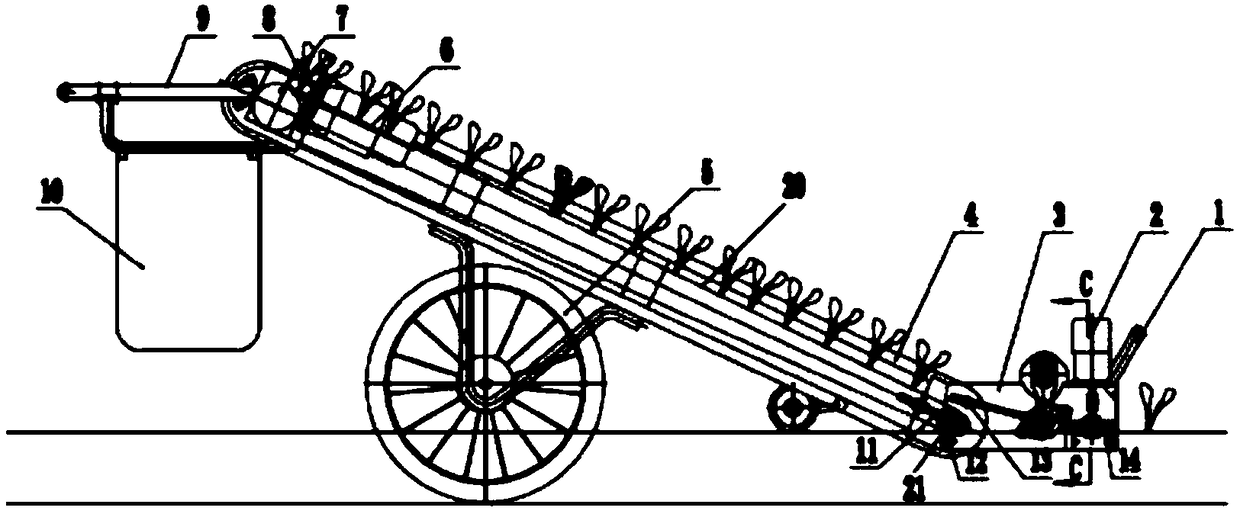

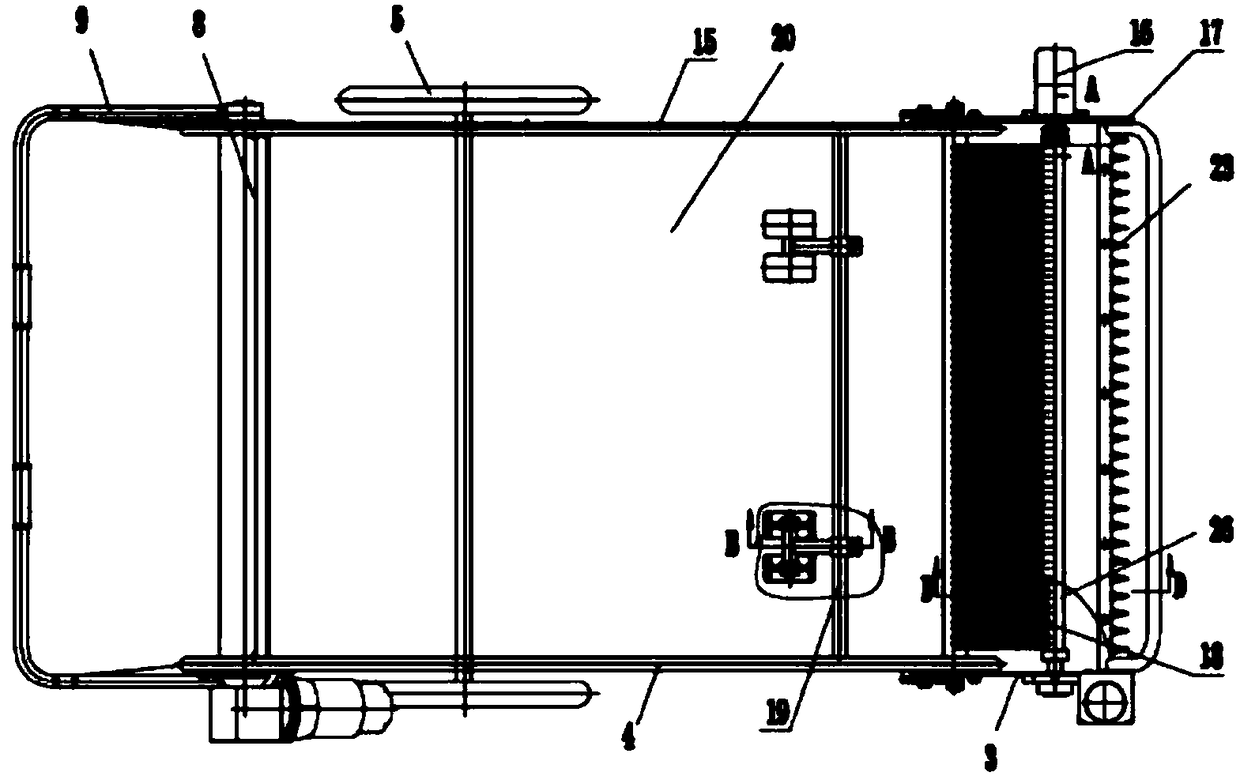

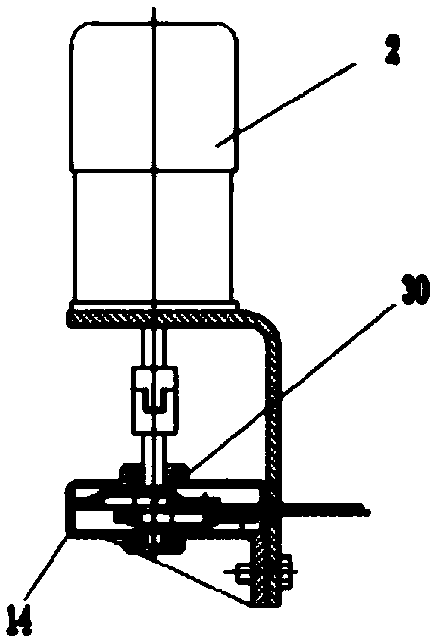

[0028] The basic structure of the orderly vegetable harvester of the present embodiment is as follows: figure 1 As shown, the upper line of the two horizontal lines in the figure indicates the plane of the vegetable ridge, and the lower line indicates the plane of the vegetable ditch. The machine includes a loop belt conveying device with a low front and a high rear placed on the walking wheels 5. The two sides of the device are the left conveying bracket 15 and the right conveying bracket 4 supporting the conveyor belt 20 respectively, and the rear end is installed to drive the conveying belt of the conveyor belt. The motor 6 and the gearbox 7 are also equipped with a detachable dish-collecting baffle plate 8 spanning between the left conveying support 15 and the right conveying support 4, and a handrail 9, which hangs a collection bag 10 under the handrail 9. When orderly harvesting is required, the orderly arranged vegetables conveyed by the conveying device from front to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com