Dual-magnet midrange compression drivers

A compression drive, dual magnetic circuit technology, applied in the direction of sensors, electrical components, etc., can solve the problems of limited space utilization and sound quality improvement, poor vocal performance of the dome sound membrane, etc., to achieve good vocal performance, Compact structure, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

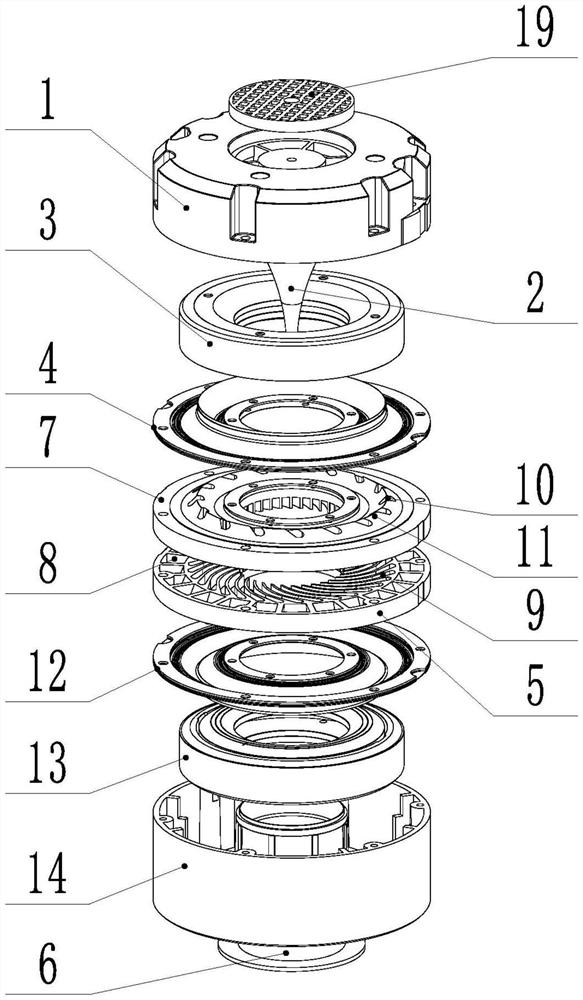

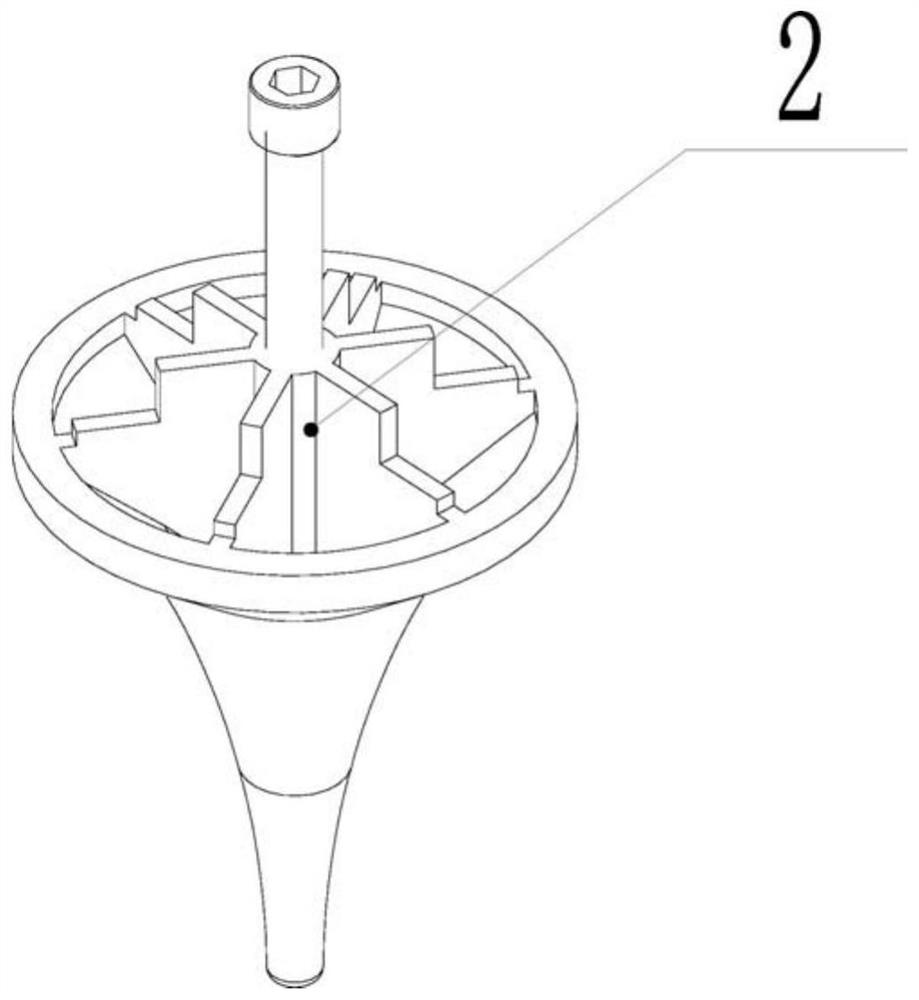

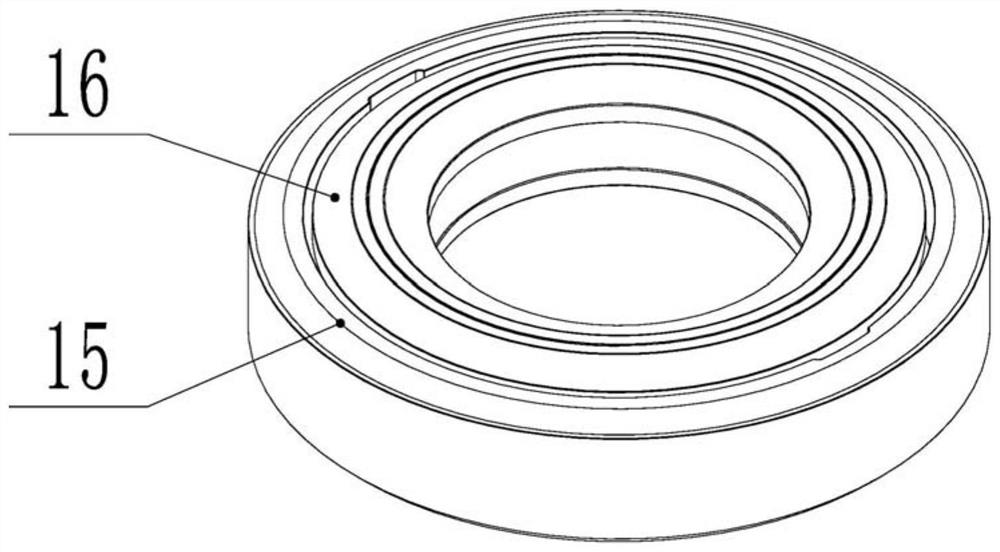

[0024] The reference signs in the drawings of the specification include: upper cover 1, central column 2, first magnetic circuit 3, first vibrating plate 4, second equalizer 5, foam 6, first equalizer 7, groove 8, Equalizing groove 9, through hole 10, annular protrusion 11, second vibrating plate 12, second magnetic circuit 13, base 14, housing 15, magnet 16, diaphragm 17, voice coil 18, cooling block 19.

[0025] Examples are attached figure 1 Shown: A mid-range compression driver with dual magnetic circuits, including a top cover 1, a center column 2, a first magnetic circuit 3, a first vibrating plate 4, a first equalizer 7, a second magnetic circuit 13, and a second vibrating plate 12. The second equalizer 5 and the base 14, the upper cover 1, the center column 2, and the base 14 are all made of aluminum, and the upper cover 1 is threadedly connected with a cooling block 19, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com