Quantum-level cascaded laser with vertical cavity surface emission function

A vertical cavity surface emission, quantum cascade technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of reducing the threshold current density of devices, increasing the difficulty of material growth, unfavorable device heat dissipation, etc., to increase non-radiation Effects of attenuation lifetime, lower device threshold, and shortened device cavity length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

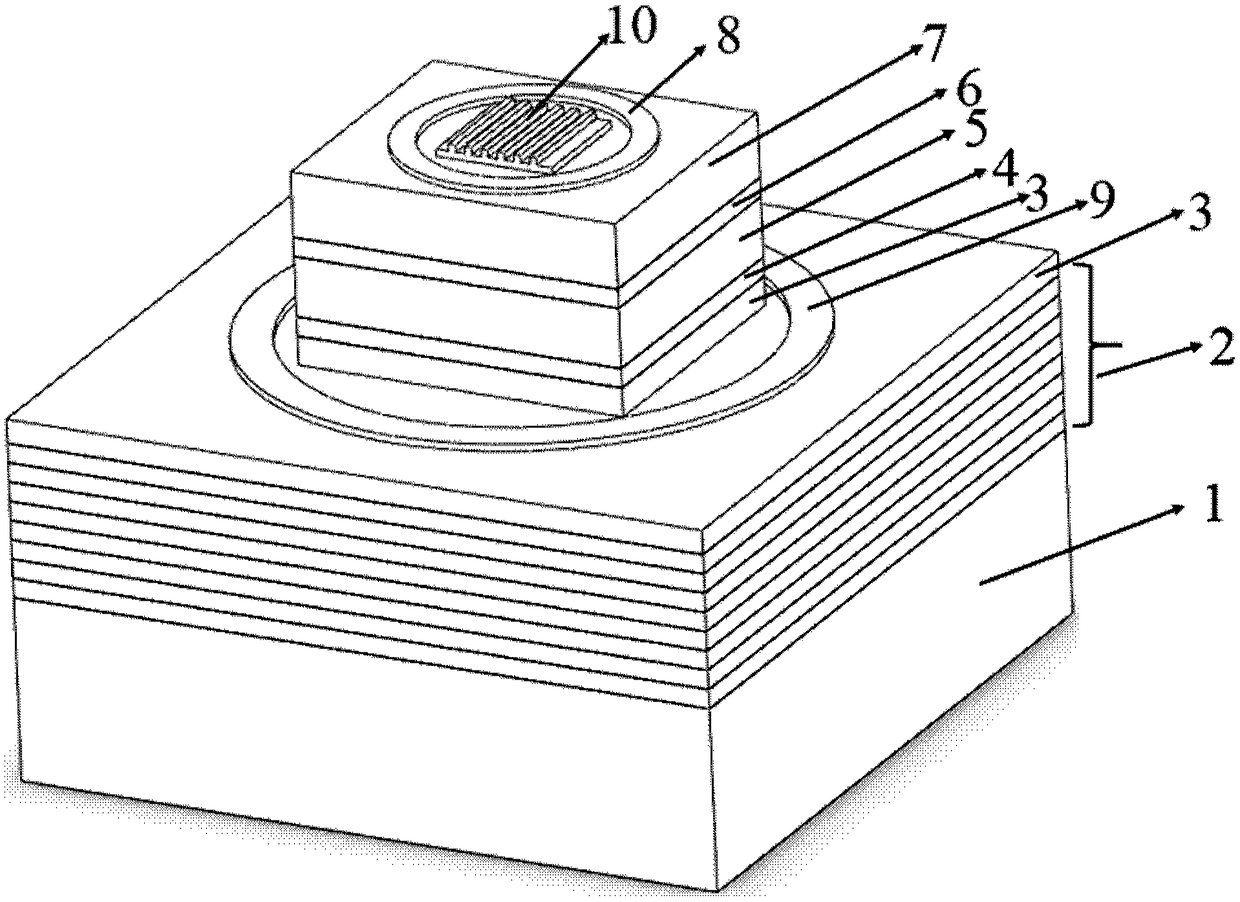

[0029] An embodiment of the present invention provides a vertical cavity surface emitting quantum cascade laser, please refer to figure 1 ,include:

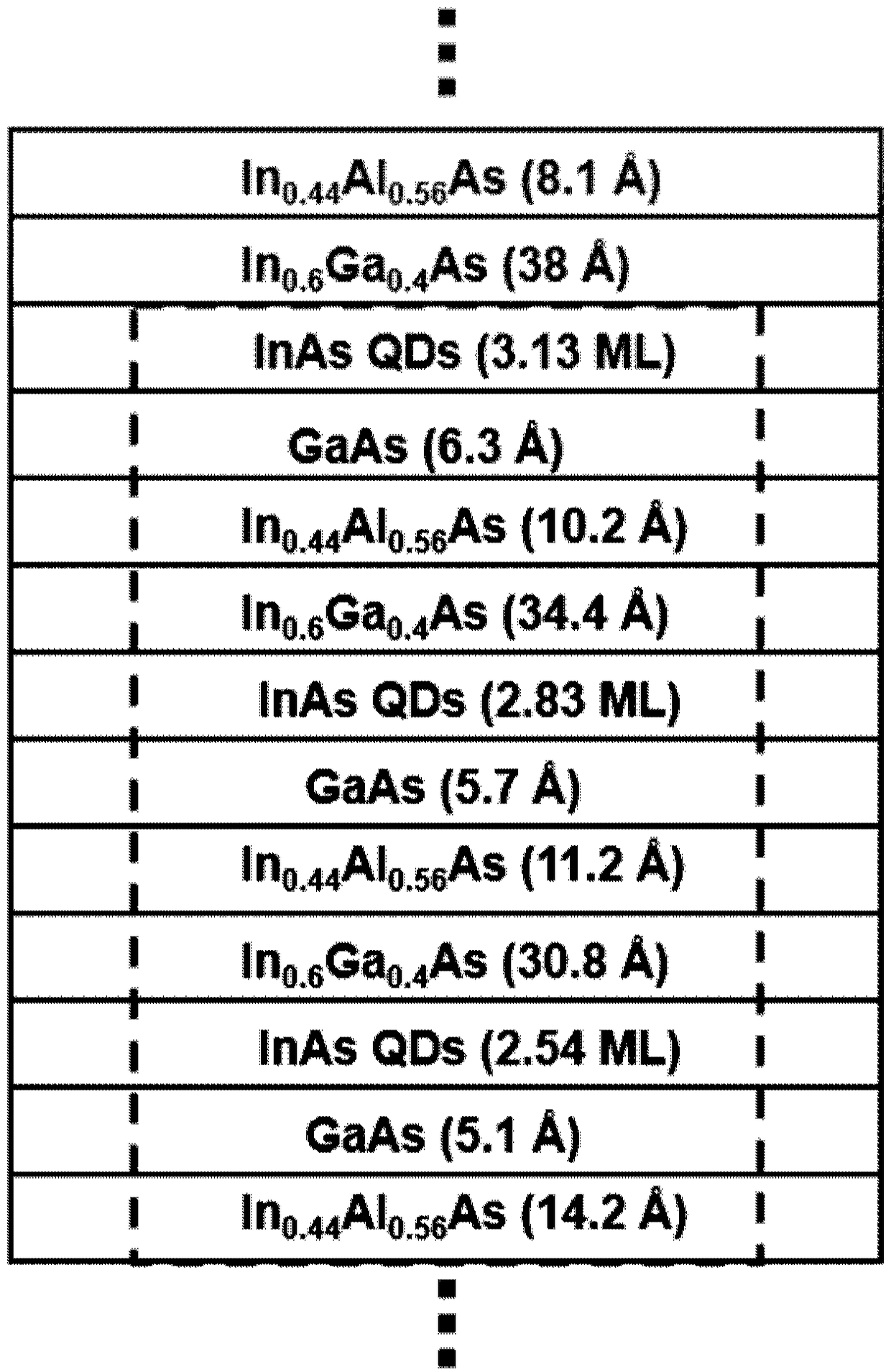

[0030] Quantum dot active region layer, inserting quantum dot intercalation in each cycle of the active region of the laser to form a quantum dot active region layer;

[0031] In this embodiment, by inserting two or more layers of quantum dot intercalation in each period of the active region of the laser, the free movement of electrons parallel to the plane of the quantum well is restricted, so that the originally continuous subbands become truly energy isolated. The inserted quantum dot state is used as the final state of the electronic radiation transition, breaking the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com