Aperture and pitch measuring device and measuring method for large-sized tube sheet

A measuring device, a large-scale technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high labor intensity, low degree of automation, complex operation, etc., to avoid large measurement errors, avoid manual intervention, and improve detection. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

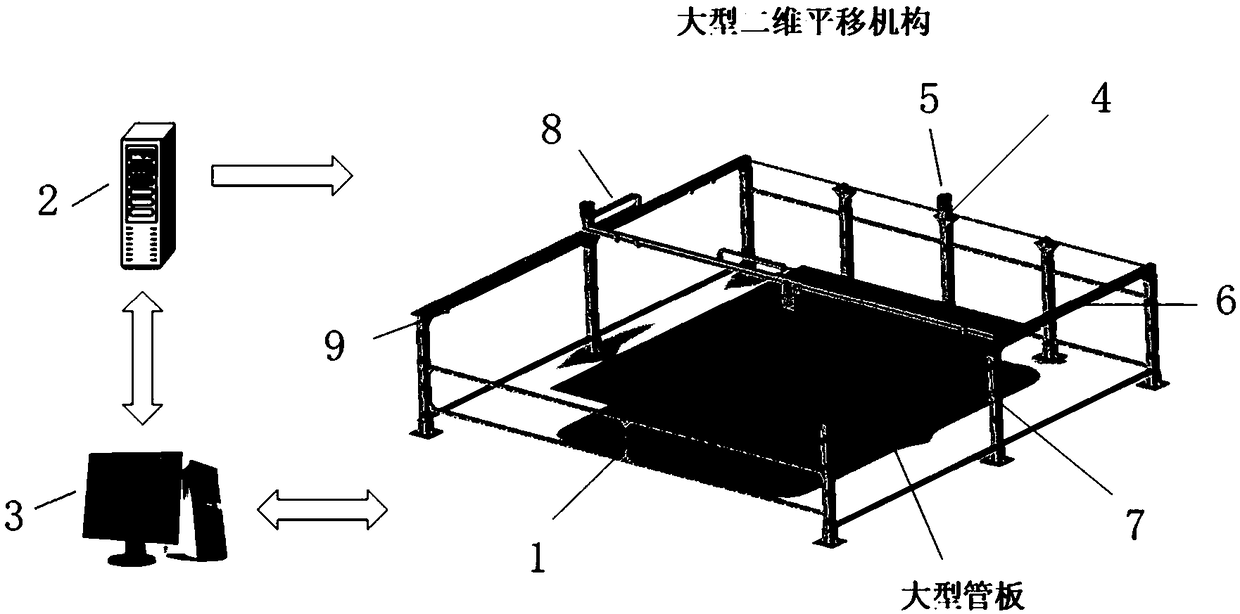

[0034] see figure 1 , The measuring device of the present invention is composed of a large-scale two-dimensional translation mechanism, a measuring head mechanism 1, a controller 2 and a computer 3 and the like. Among them, the large-scale two-dimensional translation mechanism mainly includes a gantry-type two-dimensional translation slide table 6 and a profile support 7 in terms of functions. The gantry-type two-dimensional translation slide table 6 includes servo motor 5, reducer 4, drag chain 8, guide groove, limit switch 9 and other accessories; the profile support 7 is mainly used to support and fix the two-dimensional translation slide table to ensure the positioning of the translation mechanism accuracy and stability. The transmission mechanism of the gantry-type two-dimensional translation slide table 6 adopts a synchronous transmission mode to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com