Wet acetylene automatic unloading calcium carbide crushing explosion-proof dehumidification ash-free dust removal system

A dust removal system and explosion-proof technology, which is applied to machines/engines, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of small exhaust air volume, limited exhaust air volume of exhaust fans, time-consuming and laborious ventilation ducts, etc., so as to increase the air volume. , improve efficiency, speed up the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

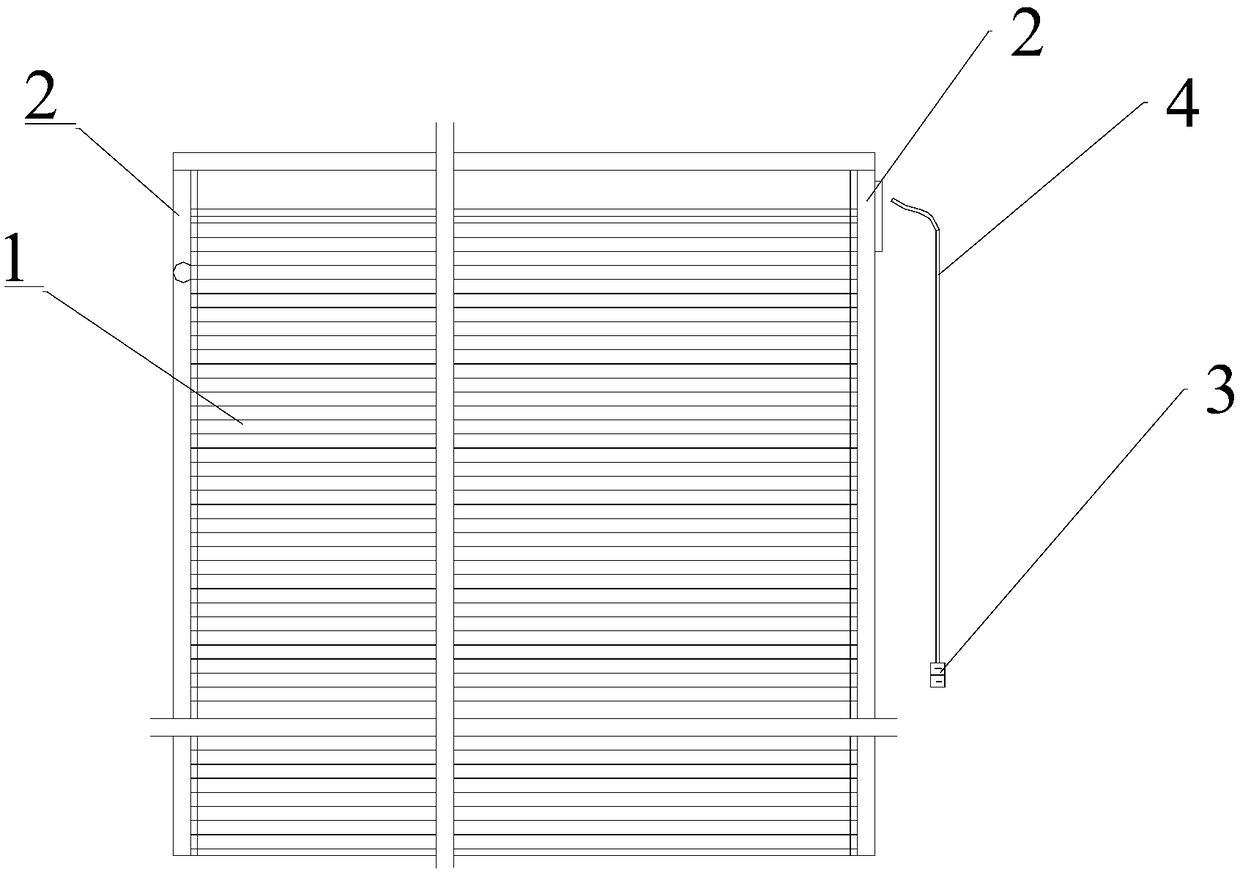

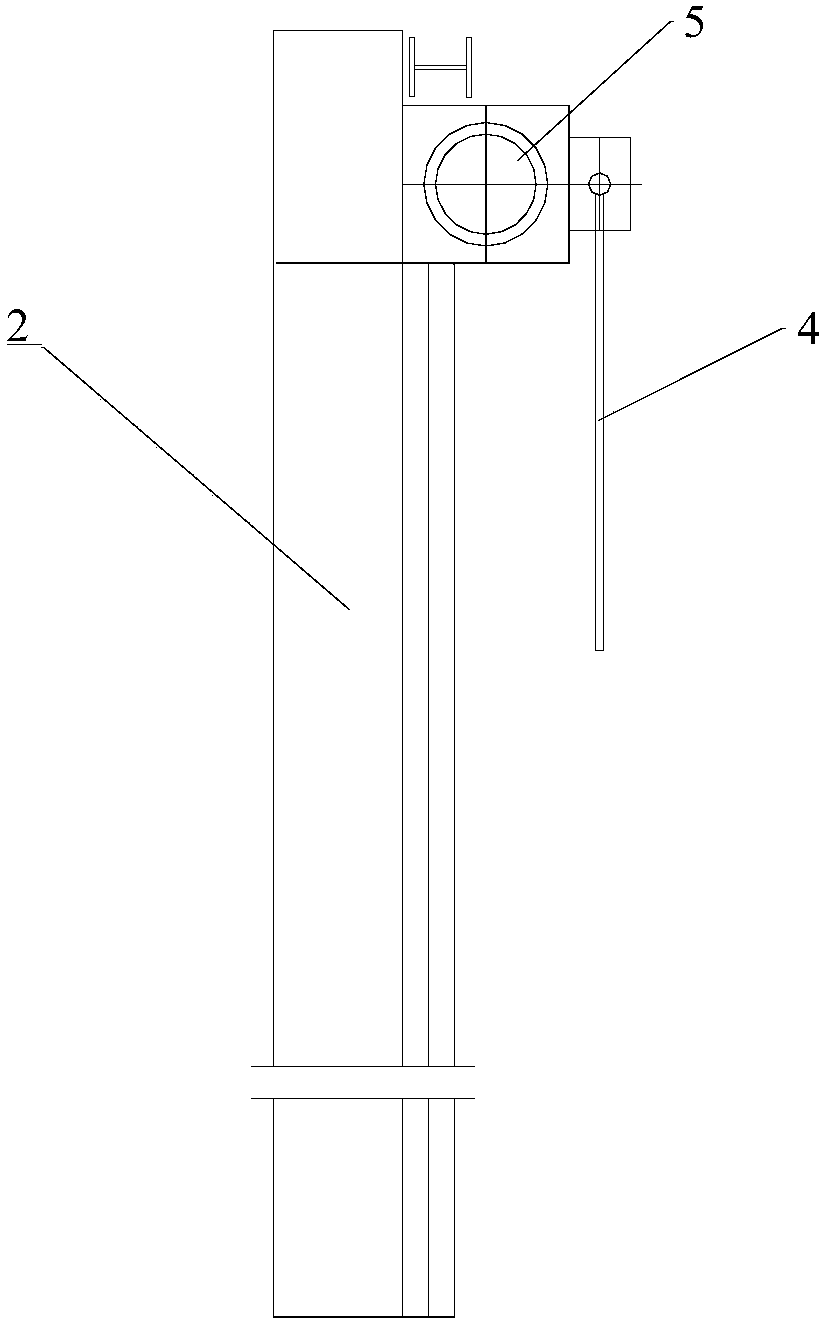

[0030] Such as Figure 1-7 As shown, the wet acetylene automatic unloading calcium carbide crushing explosion-proof dehumidification and dust-free dust removal system includes: rolling shutter door 1, door frame 2, control switch 3, wire 4, reel 5, gear 6, rack 7, electromagnetic coil 8, spring 9. Iron core 10, shell 11, power supply 12, wire 13, speed control switch 14, motor 15.

[0031] The edges on both sides of the rolling door 1 are slidably fitted in the guide grooves 201 of the door frame 2 on both sides. The rolling door 1 is wound on the outside of the reel 5 on the upper side of the door frame 2, and one end of the reel 5 is coaxially fixed. A gear 6 is connected, and the gear 6 is in transmission connection with the rack 7 on one side. The upper side of the door frame 2 is also provided with a rolling door control device. The rolling door control device includes a casing 11. An iron core 10 is slidably fitted, and one end of the iron core 10 elastically cooperates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com