Polylactic acid fiber vertical cotton material and preparation method thereof

A technology of polylactic acid fiber and polylactic acid, which is applied in the field of nonwoven materials, can solve the problems such as the absence of polylactic acid fiber upright cotton products and the inability to produce polylactic acid fiber upright cotton materials, and achieve the effect of increasing elasticity and upgrading performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

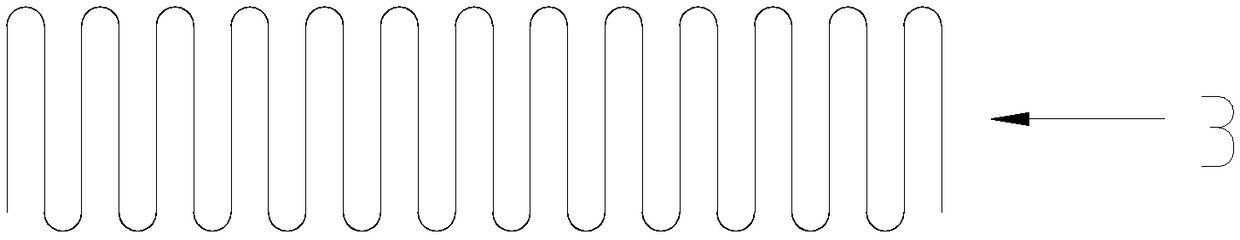

[0031] see figure 1 , a kind of polylactic acid fiber upright cotton material of the present embodiment, it is made by the polylactic acid fiber material of 100%, and the grammage of the upright cotton material of 1cm thickness is 40-60g / m 2 .

[0032] The polylactic acid fiber erecting cotton material of this embodiment includes an erecting cotton layer 3 in the middle, and the material of the erecting cotton layer 3 is polylactic acid fiber.

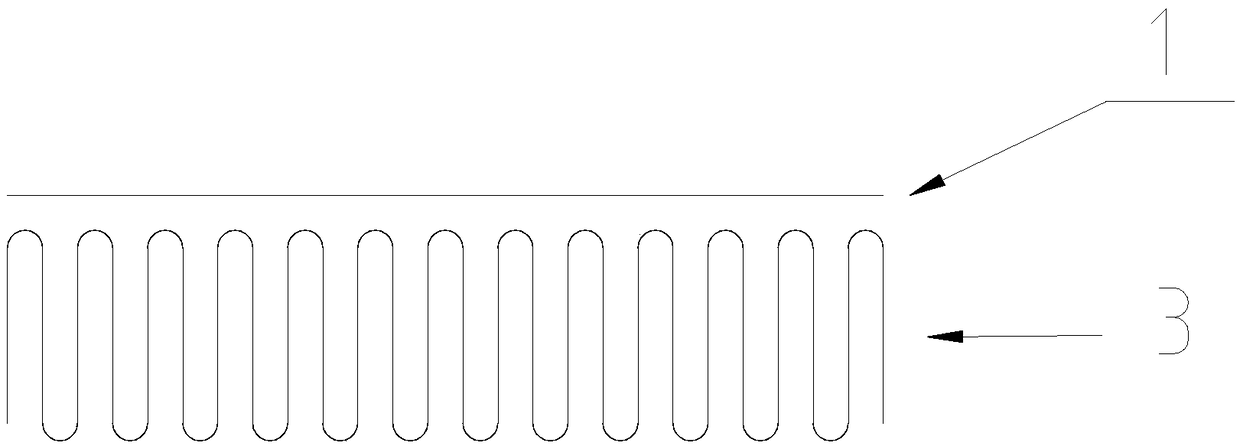

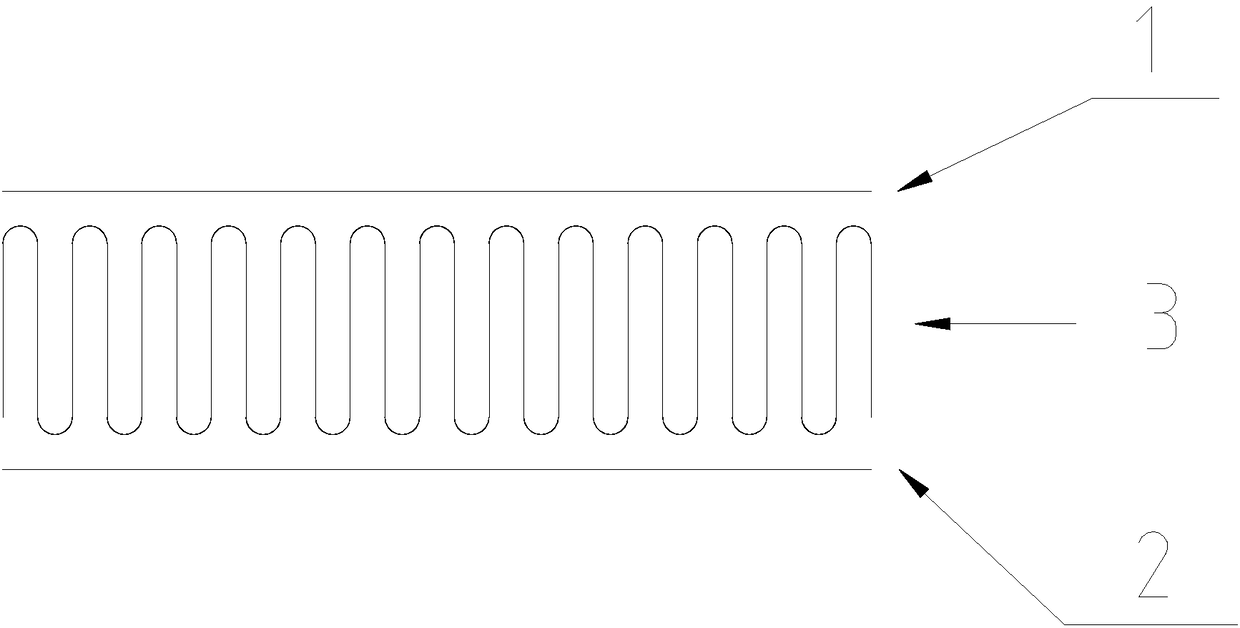

[0033] In some other embodiments, the upright cotton material also includes a first flat layer 1 above the upright cotton layer 3 and / or a second flat layer 2 below the upright cotton layer 3, such as figure 2 and image 3 . The material of the first flat layer 1 and the second flat layer 2 is also polylactic acid fiber.

[0034] Every 100g of polylactic acid fiber includes 20g-100g of two-component polylactic acid fiber, no more than 80g of single-component polylactic acid fiber and no more than 80g of three-dimensional polylacti...

Embodiment 2

[0058] The polylactic acid fiber erecting cotton material and its preparation method in this embodiment are basically the same as in the first embodiment, the difference is that all the polylactic acid erecting cotton materials in this embodiment are prepared from two-component polylactic acid fibers.

[0059] The two-component polylactic acid fiber in this embodiment: fineness 3.25dtex, average length 56mm.

Embodiment 3

[0061] The polylactic acid fiber upright cotton material and its preparation method in this embodiment are basically the same as in Example 1, the difference is that the polylactic acid upright cotton material in this embodiment consists of 20% by mass of two-component polylactic acid fibers and 80 The three-dimensional polylactic acid fibers of % mass parts are prepared, that is, 100g of polylactic acid upright cotton materials include 20g of two-component polylactic acid fibers and 80g of three-dimensional polylactic acid fibers.

[0062] Two-component polylactic acid fiber in this example: fineness 2.53dtex, average length 62mm, number of crimps 12 / 25mm; polylactic acid three-dimensional fiber: fineness 3.33dtex, average length 64mm, number of crimps 12 / 25mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com