Coal mine winch rope arranging device

A winch, coal mine technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of the rope off, the mine car falling way, the wire rope is subjected to large force, etc., and achieves simple operation mode, safe and reliable operation mode, and manufacturing process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

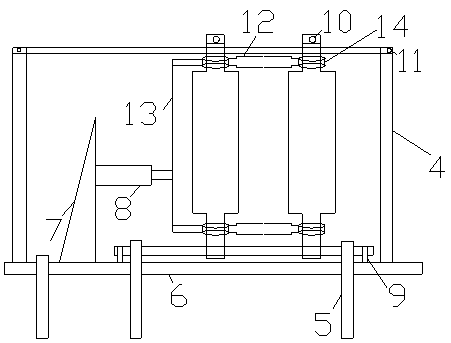

[0012] When in use, operate the hydraulic oil cylinder 8 to extend or contract, and drive the rectangular connecting plate 13 to move left and right, thereby pushing the two moving rollers 15 to move in the sliding groove 2 of the sliding groove steel plate 1, and the wire rope on the winch is located between the two moving rollers. Between the drums 15, during the movement of the two moving rollers 15, the wire ropes of the winch drums are arranged in an orderly manner, which effectively prevents the accumulation problem at one position of the winch drum, and the hydraulic cylinder 8 is telescopic.

[0013] Bottom plate 6 is the thick steel plate of 4cm, and length is 1m, and width is 0.5m, and two mobile roller diameters are all 0.5m, and height is 0.5m, and small roller diameter is 0.3m, and long 0.15m, and ground anchor is long 2m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com