Handlebar

A technology of handlebars and handlebars, applied in the field of handlebars, can solve problems such as insufficient friction, inconvenient operation, hidden safety hazards, etc., and achieve the effects of convenient installation and disassembly, convenient opening and fastening, and flexible and diverse shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

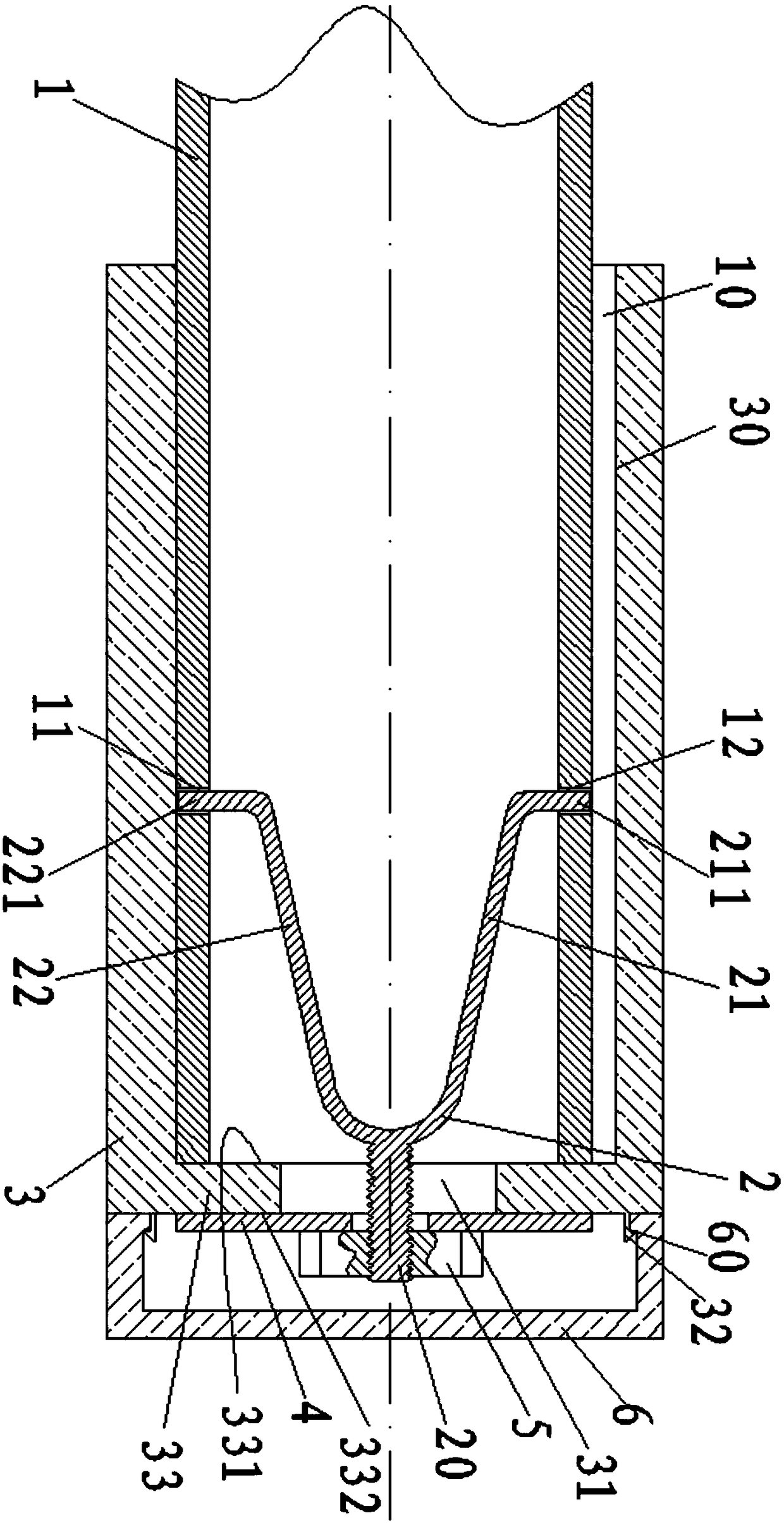

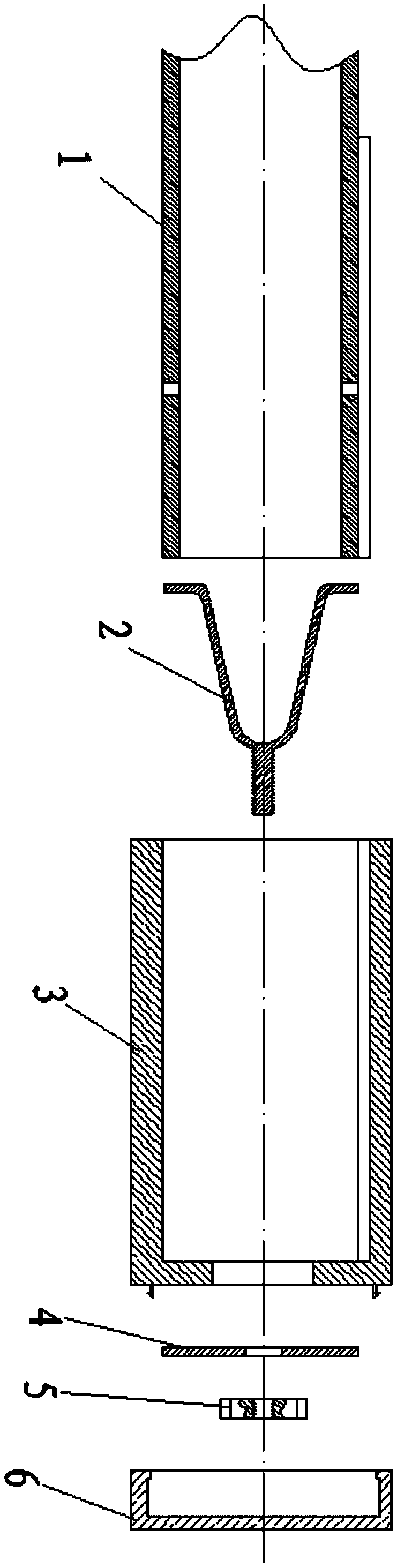

[0027] The technical solution of the handlebar of the present invention will be further described in detail below in conjunction with the embodiments shown in the accompanying drawings.

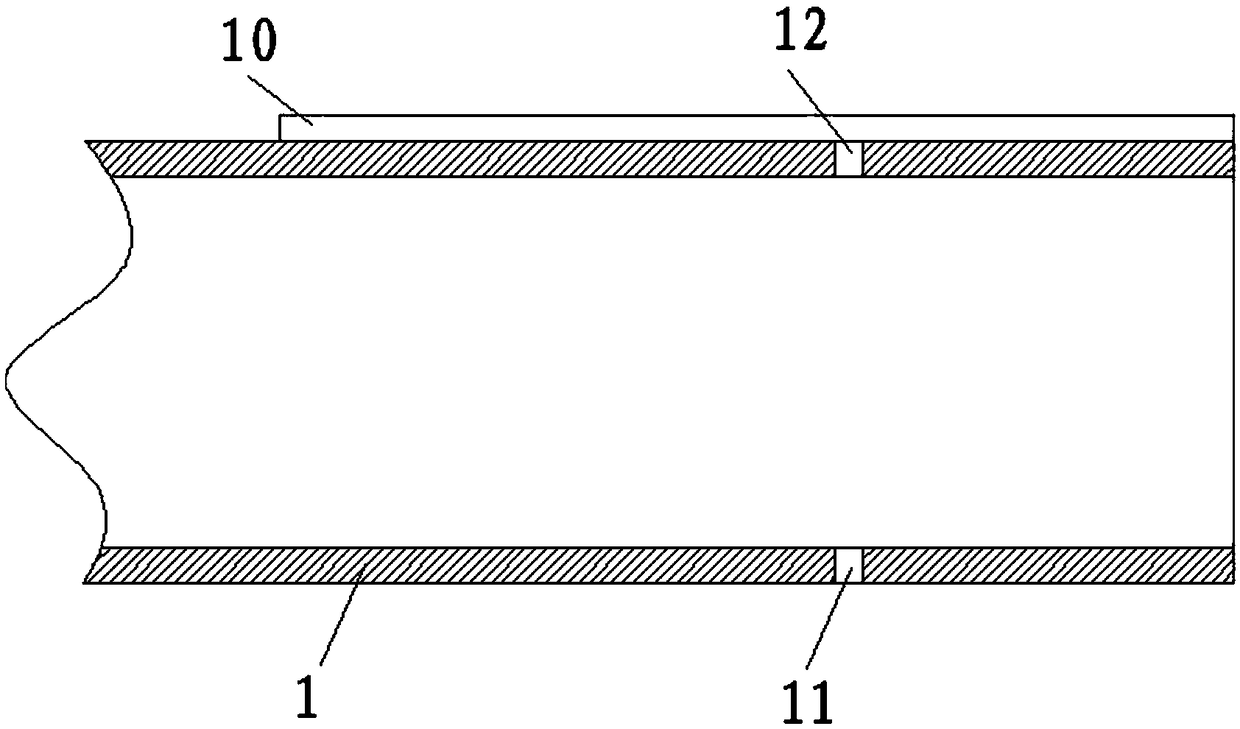

[0028] as attached figure 1 to attach Figure 8 As shown, a handlebar includes a handlebar metal pipe 1 and a handle cover 3, the handle cover 3 includes a first port 34 and a second port 35, and the handle cover 3 is sleeved on the vehicle through its first port 34. On the outer wall of the metal pipe 1, the handle cover 3 is the part that the operator holds with his hands, and the first through hole 11 and the second through hole 12 are set on the pipe wall of the handlebar metal pipe 1. A Y-shaped connector 2 is arranged in the metal pipe 1, and the Y-shaped connector 2 includes a bolt 20, a first connecting arm 21 and a second connecting arm 22, and the first connecting arm 21 and the second connecting arm 22 are extended from one end of the bolt 20. Two connection arms 22, the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com