Composite fiber, composite board and method for preparing composite board

A composite fiber and composite board technology, applied in chemical instruments and methods, protective equipment, synthetic resin layered products, etc., can solve problems such as limited strength and inability to provide protection, and achieve good structural strength and good impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following figures and preferred embodiments of the present invention further illustrate the technical means adopted by the present invention to achieve the intended purpose of the invention.

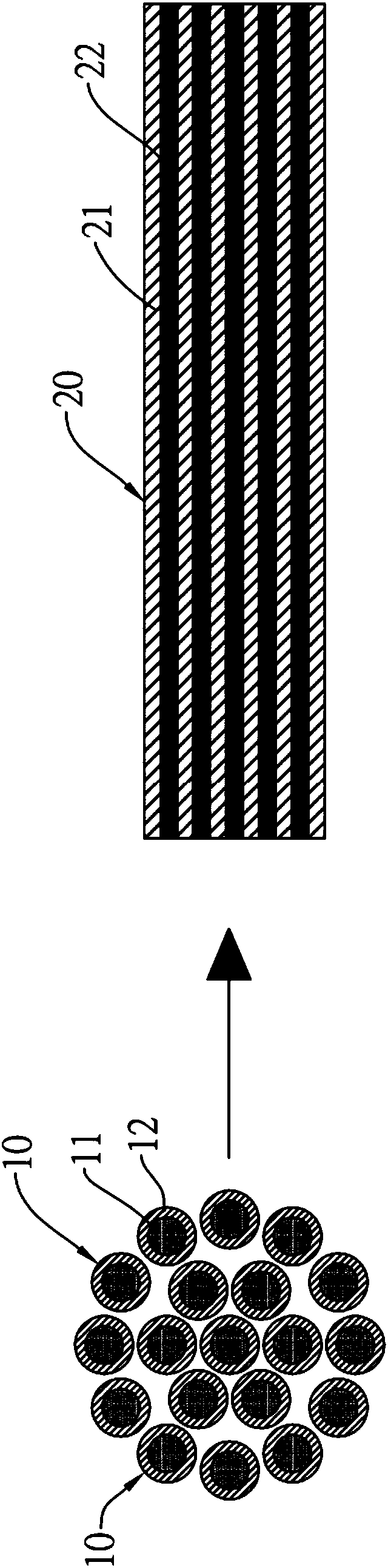

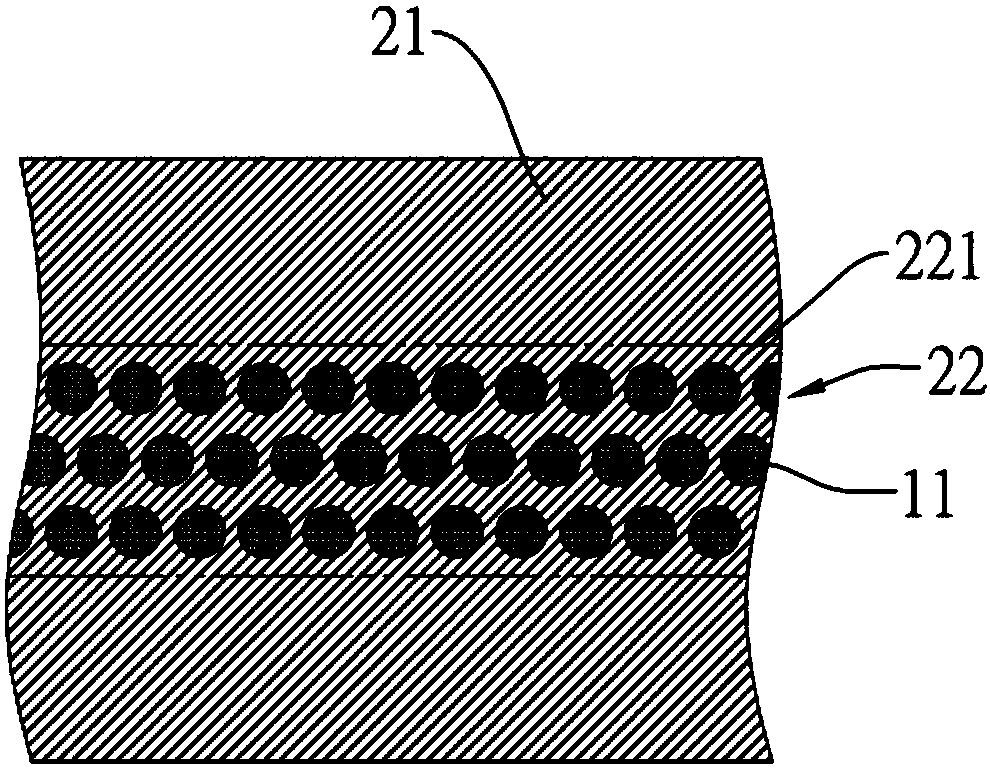

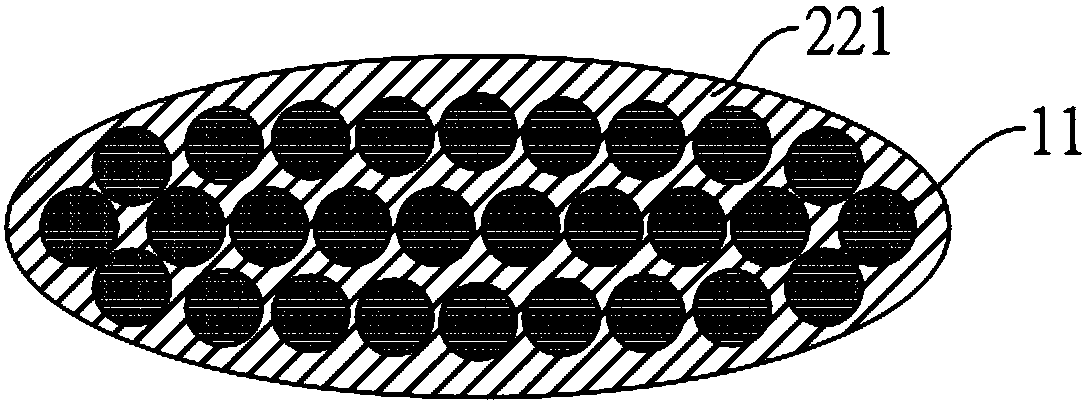

[0027] See figure 1 As shown, the composite fiber 10 of the present invention is composed of a core material 11 and a shell 12, the core material 11 is in the shape of a circular elongated strip, the shell 12 is formed around the core material 11, and the shell 12 The melting temperature is lower than the melting temperature of the core material 11, the strength of the outer shell 12 is higher than the strength of the core 11, and the outer shell 12 of each composite fiber 10 is closely connected with the outer shell 12 of an adjacent composite fiber 10. In addition, the composite fiber 10 is roughly in the shape of a round strip.

[0028] In a preferred embodiment, the core material 11 is made of polypropylene copolymer or polypropylene homopolymer, and the outer shell 12 is made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com