Speed-recognition-based automatic fixture for robot

A voice recognition and robot technology, applied in chucks, manipulators, manufacturing tools, etc., can solve problems such as safety accidents and affecting the use of fixtures, and achieve the effects of protecting workpieces, facilitating processing and use, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

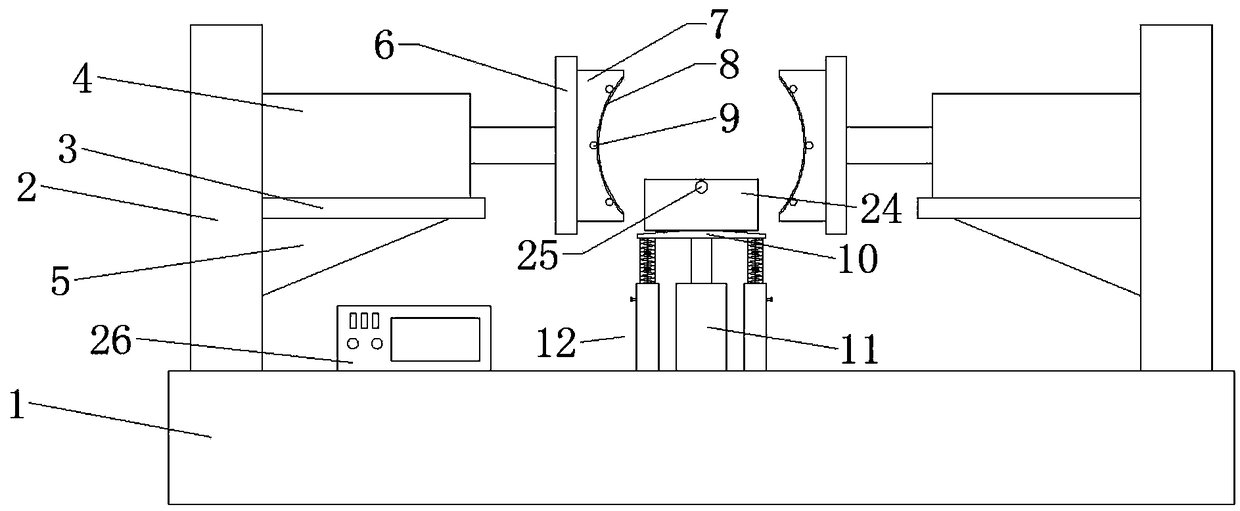

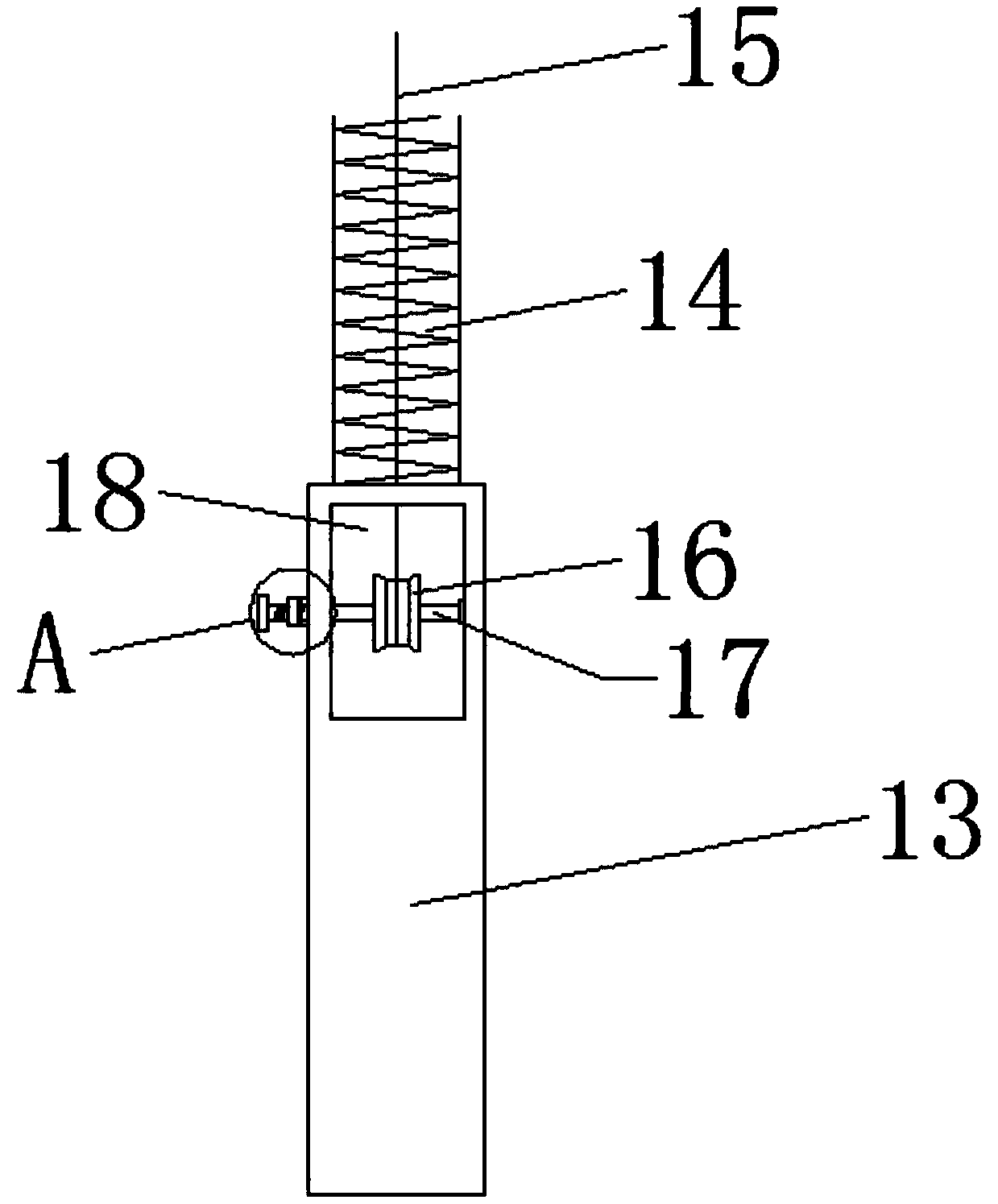

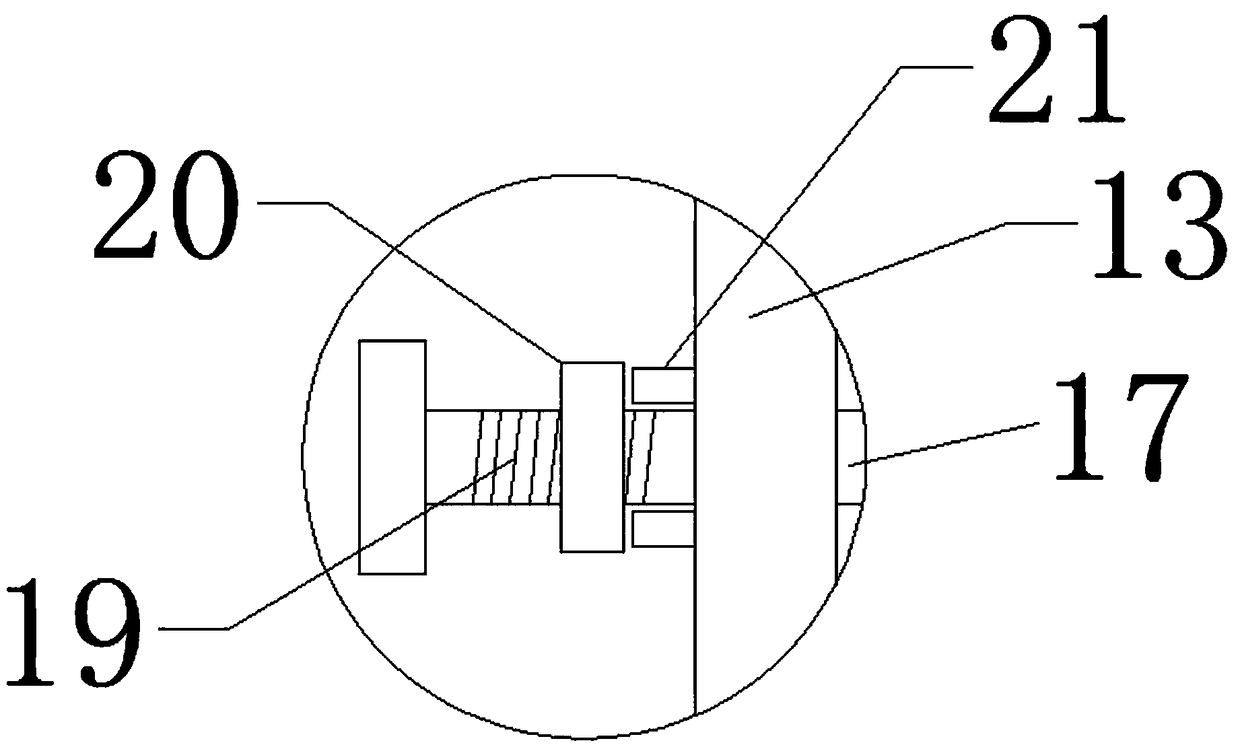

[0021] Please refer to the figure, in the embodiment of the present invention, a robot automatic fixture based on speech recognition includes a base 1, a side support 2, a cylinder seat 3, a clamping cylinder 4, a rib 5 and a splint 6; the base 1 Both ends are fixed with vertical side brackets 2, and the cylinder block 3 is horizontally fixed in the middle of the side bracket 2, and is fixedly welded by reinforcing ribs 5 to enhance the strength of the cylinder block 3, and the cylinder blocks 3 on both sides are on the same horizontal plane. The clamping cylinder 4 is horizontally installed on the cylinder base 3, and a vertical splint 6 is fixed on the end of the output shaft of the clamping cylinder 4 on both sides. Move so that the splints 6 on both sides apply pressure to the workpiece.

[0022] The same clamping blocks 7 are fixedly installed on the splints 6 on both sides, and the two clamping blocks 7 are arranged opposite to each other. The opposite side walls of the ...

Embodiment 2

[0026]A plurality of first pressure sensors 9 are installed on the clamping block 7, a second pressure sensor 23 is installed on the top of the placement plate 10, a speech recognition module 25 is installed on the baffle plate 24, and a controller is installed on the base 1 26. The clamping cylinder 4, the first pressure sensor 9, the lifting cylinder 11, the second pressure sensor 23, and the voice recognition module 25 are all connected to the controller 26, and the first pressure sensor 9, the second pressure sensor 23 , the voice recognition module 25 is connected to the input end of the controller 26, and the clamping cylinder 4 and the lifting cylinder 11 are connected to the output end of the controller 26, and the first pressure sensor 9, the second pressure sensor 23, and the voice recognition module 25 will monitor the The signal is transmitted to the controller 26, and the action of the clamping cylinder 4 and the lifting cylinder 11 is controlled according to the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com