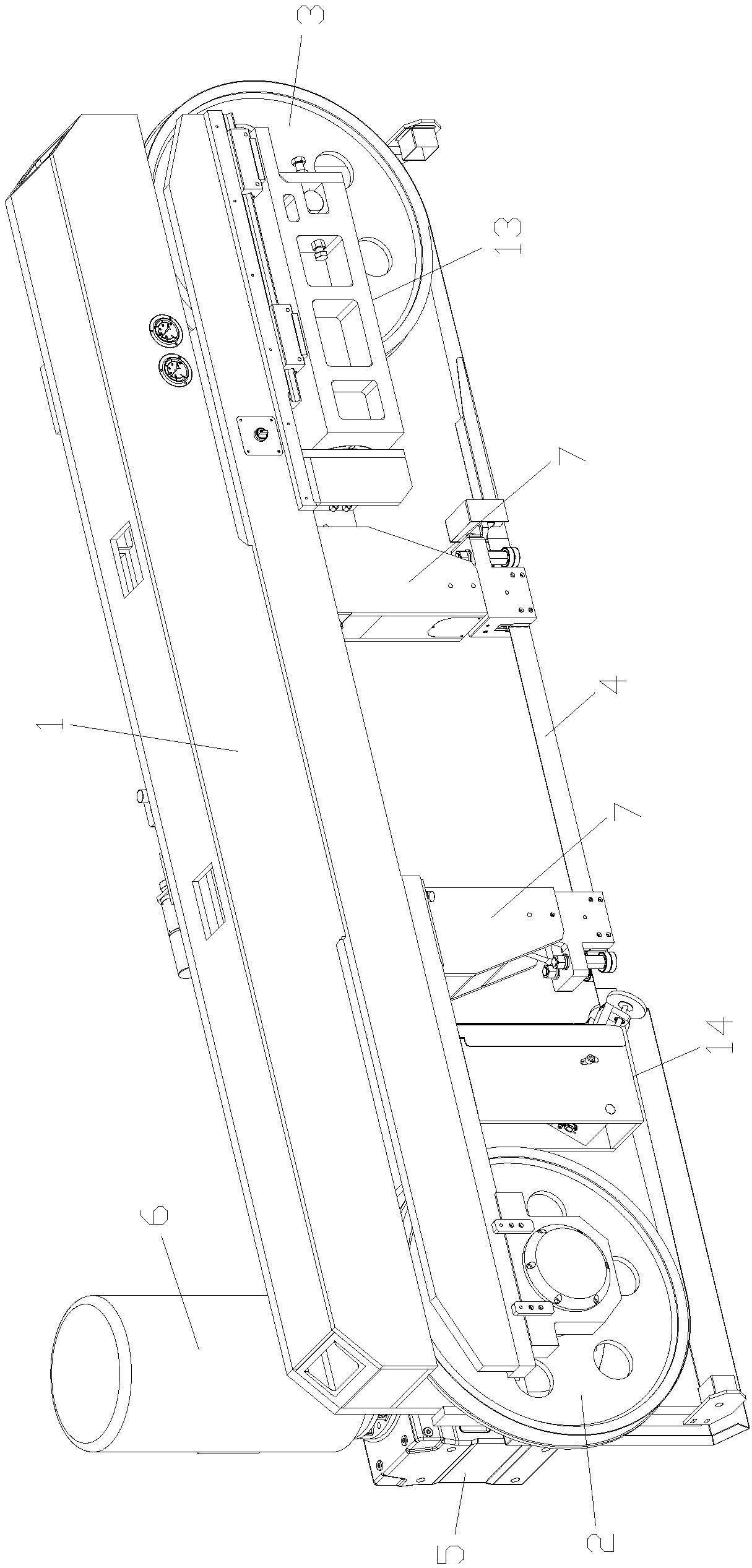

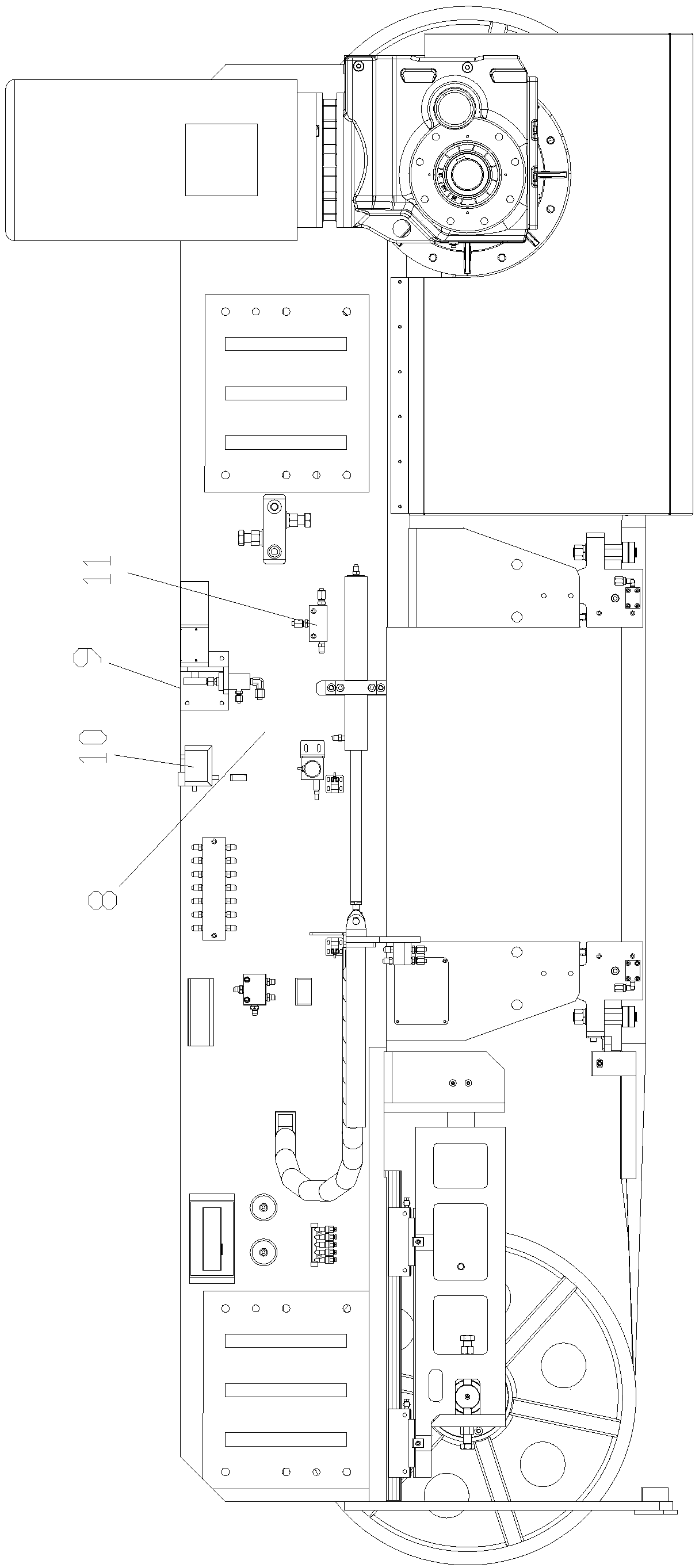

Impulse control saw cutting saw frame

A technology of pulse control and saw frame, which is applied in the direction of metal sawing equipment, sawing machine devices, manufacturing tools, etc., can solve problems such as difficult to achieve fast sawing, achieve improved sawing effect, good use effect, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

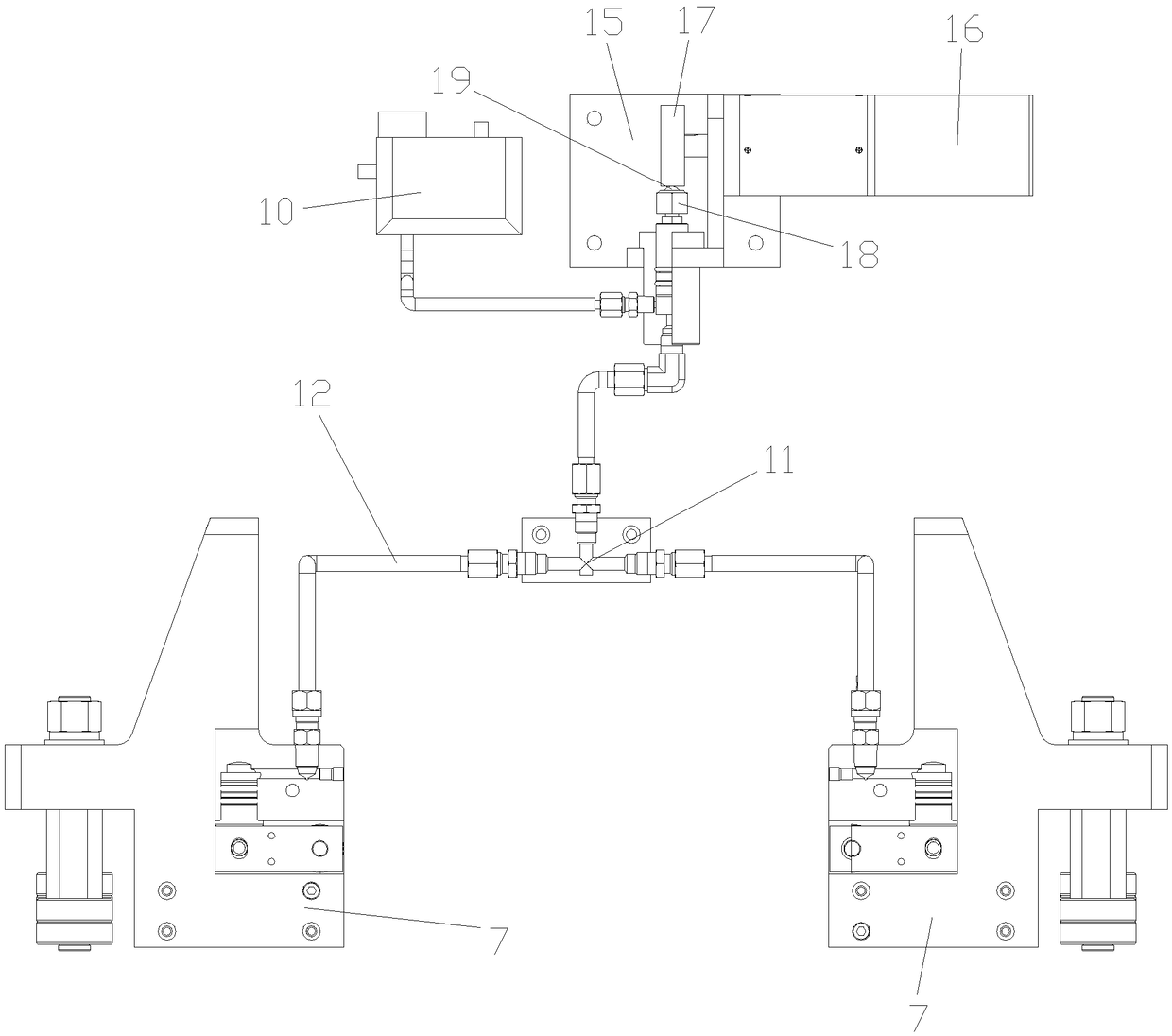

[0033] The band saw blade guide unit 13 is provided with a saw arm 20 installed on the lower end of the saw frame 1. A guide seat 21 is installed at the lower end of the saw arm 20. A through groove 21-1 for the band saw blade 4 to be placed inside the guide seat 21 is provided. A pair of guide head pressing blocks 22 distributed front and back are installed at the upper end of 21-1, and a pair of first deep groove ball bearings 23 are rotationally connected between the two guide head pressing blocks 22, wherein the outer peripheral surface of the first deep groove ball bearings 23 Attached to the upper end surface of the band saw blade 4, a pair of guide blades 24 placed on the front and back of the band saw blade 4 are installed at the lower end of the through groove 21-1; The long guide head shaft column 26 placed at the front and back of the band saw blade 4, the lower end of the long guide head shaft column 26 is rotatably connected with a second deep groove ball bearing 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com