Preparation method for synthesizing metal organic framework UiO-66 adsorbents by aid of mixed ligands

A technology of metal-organic frameworks and mixed ligands, applied in chemical instruments and methods, and other chemical processes, can solve the problems of not reaching the ideal hydrogen adsorption capacity, achieve good application prospects, simple preparation process and equipment, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

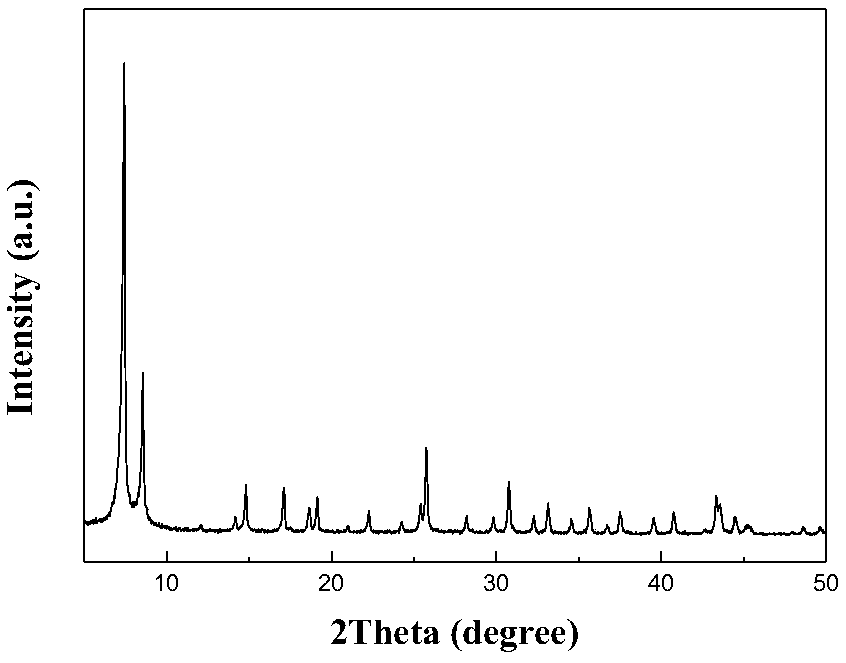

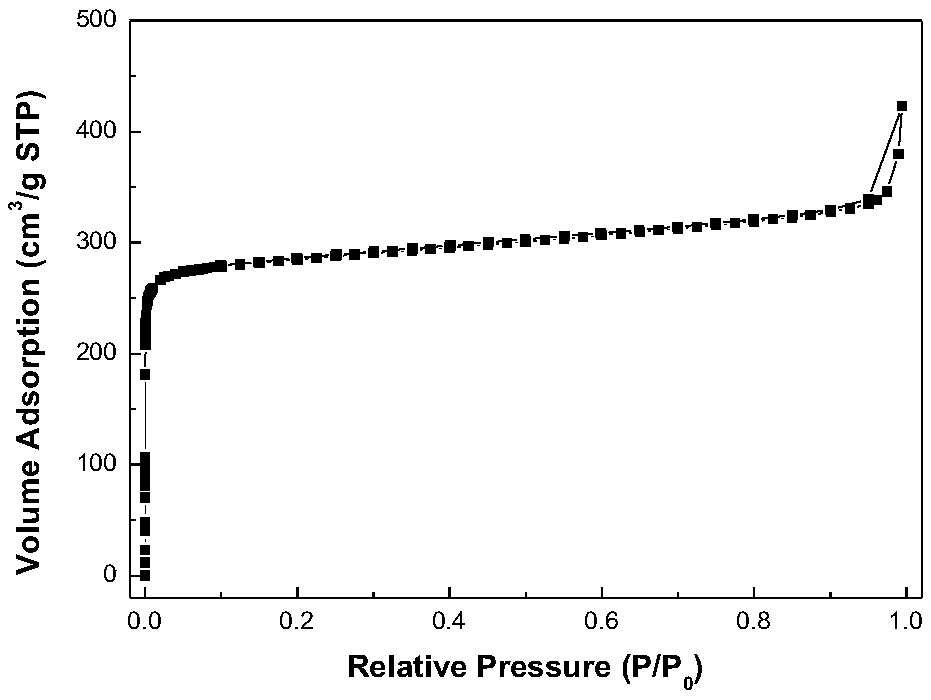

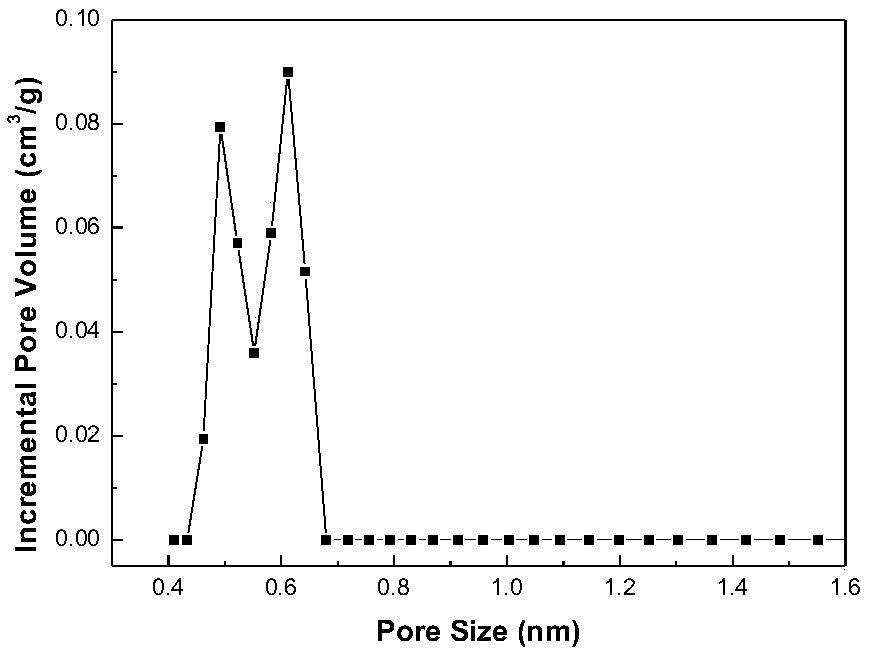

[0030] Weigh 0.35g of zirconium chloride and 2.70mL of acetic acid, and dissolve them completely in 27.30mL of N,N-dimethylformamide solvent to form solution A; weigh 0.30g of terephthalic acid, Diformic acid / terephthalic acid molar ratio is 4:6 Weigh a certain amount of 2-aminoterephthalic acid to make it completely dissolved in 30mL N,N-dimethylformamide to form solution B; put solution B in In a constant-speed water bath at room temperature, add solution A drop by drop at a constant speed to mix the two solutions evenly to obtain solution C. Transfer solution C to a stainless steel reaction kettle lined with polytetrafluoroethylene and crystallize at 150°C. 21 hours; the obtained product was washed, centrifuged, dried, and vacuum activated at 150° C. for 12 hours to obtain a mixed ligand UiO-66 adsorbent. The XRD of the adsorbent, N 2 Adsorption-desorption, pore size distribution, SEM, TGA analysis results are as follows: figure 1 , 2 , 3, 4, and 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com