A permanent magnet synchronous drive motor for electric vehicles

A drive motor and permanent magnet synchronization technology, which is applied to electric vehicles, synchronous machine parts, motors, etc., can solve problems such as excessive cogging torque, torque ripple, air gap flux density, unfavorable motor efficiency and stability, etc. Achieve the effect of improving stability and preventing magnetic flux leakage inside the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

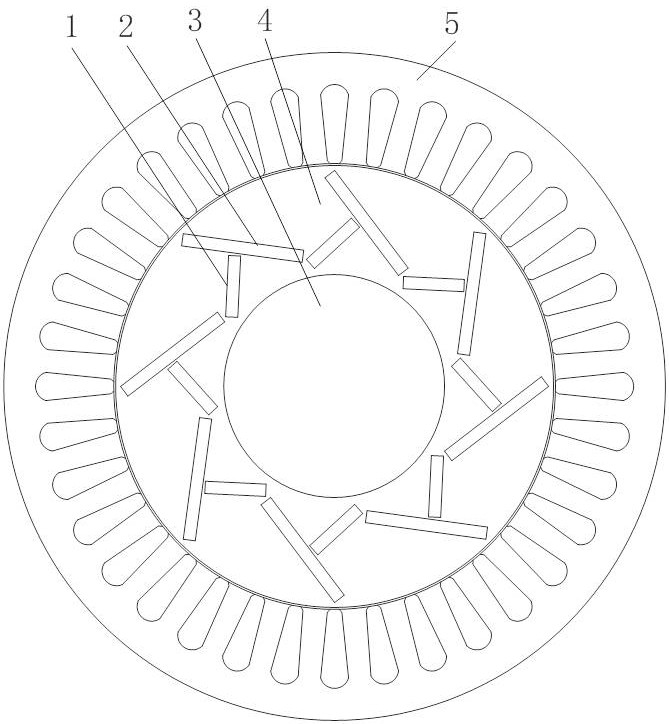

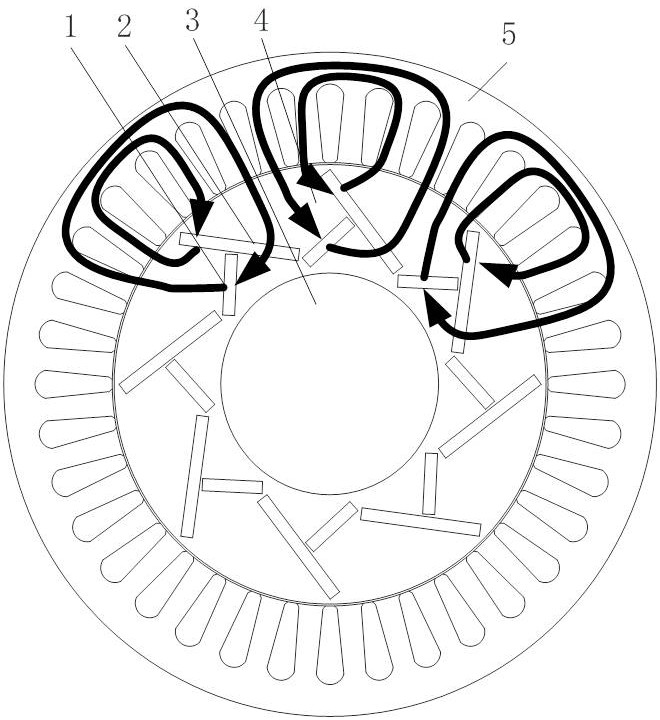

[0026] like figure 1 The shown diagram of a permanent magnet synchronous drive motor for an electric vehicle of the present invention, the shown motor includes a first permanent magnet, a second permanent magnet, a non-magnetic fixed core, a rotor core and a stator, and the drive motor is an inner rotor structure, The rotor core is internally fixed on a non-magnetically conductive fixed core.

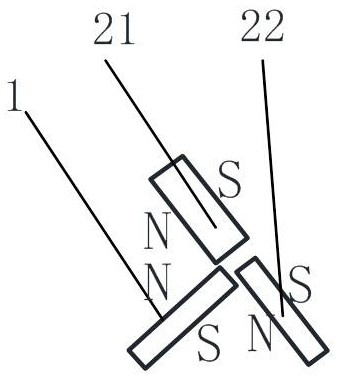

[0027] The number of the first permanent magnet and the second permanent magnet that are all planar magnets are the same and there are X, and X is an even number; the length of the first permanent magnet is greater than half of the second permanent magnet and less than 1 / 4 of the second permanent magnet three.

[0028] One end of the second permanent magnet is located outside the rotor core, and the other end is located inside the rotor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com