Preparation method of micro-fracture rock core mode

A technology of core model and micro-fracture, which is applied in the field of preparation of micro-fracture core model, can solve the problem that the core cannot be completely simulated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

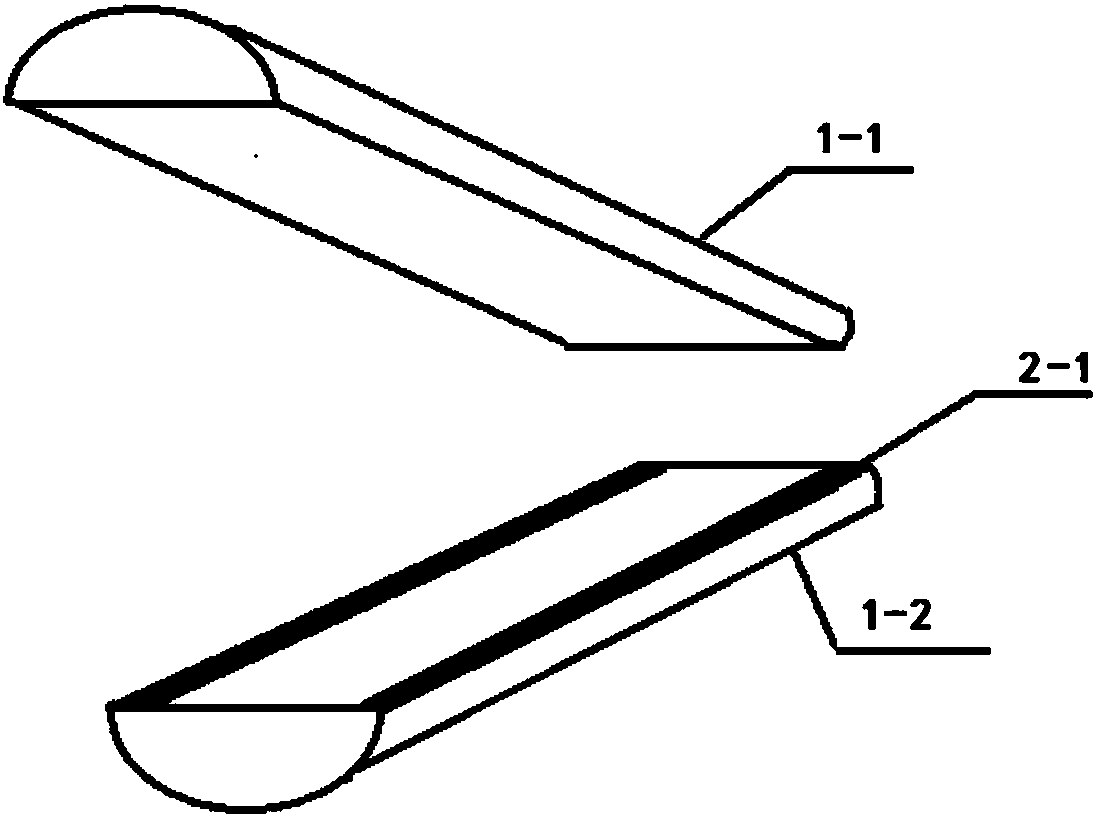

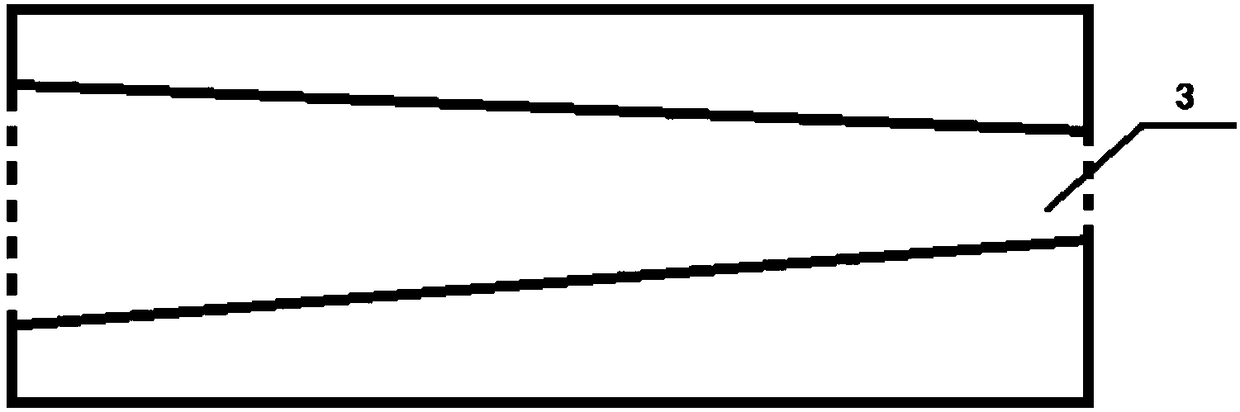

[0055] Select two compact natural core samples with a diameter of 2.5 cm and one dense artificial core sample with a diameter of 2.5 cm, split the cores along the axis, and press figure 1 The arrangement of the supports shown is to place the PET film. The length of the film is the same as that of the core sample, and the width is 0.5cm. The thickness of the film is 20 μm, 200 μm, 500 μm,

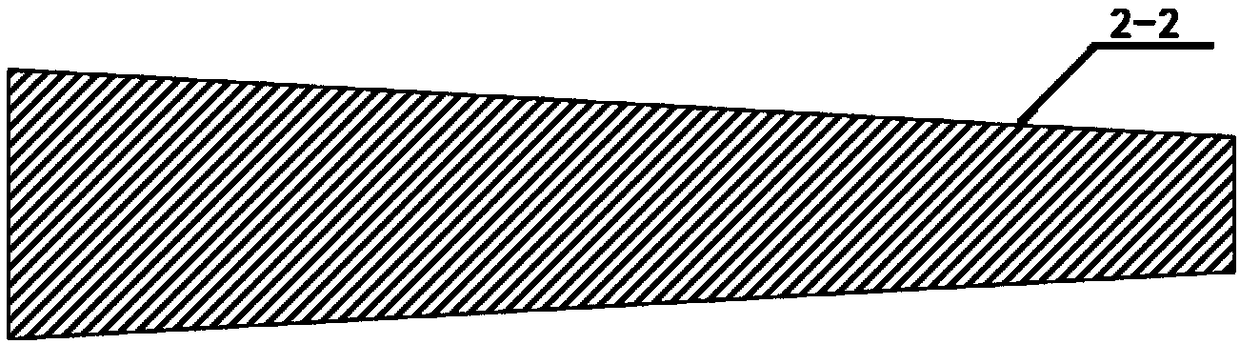

[0056] Select a dense artificial core sample with a diameter of 2.5 cm, select two wedge-shaped strips with a width of 0.5 cm, an inlet thickness of 300 μm, and an outlet thickness of 100 μm. The raw tape is fixed to form a micro-fracture core model.

[0057] The openings of the micro-fracture core models formed by the above method are 20 μm, 200 μm, 500 μm, and a wedge-shaped fracture.

[0058] Four iron cores with fracture openings of 400 μm and 500 μm were selected for comparison.

[0059] Plugging slurry formula: 2% bentonite slurry + 2% 100 mesh super calcium + 2% 400 mesh mica powder +...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com