A method for evaluating the the overall roughness of the surface of three-dimensional irregular particles

A particle surface, irregular technology, applied in image analysis, instrumentation, calculation, etc., can solve problems such as the inability to evaluate the overall roughness of the entire particle, and the inability to consider the influence of the three-dimensional irregular particle geometry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

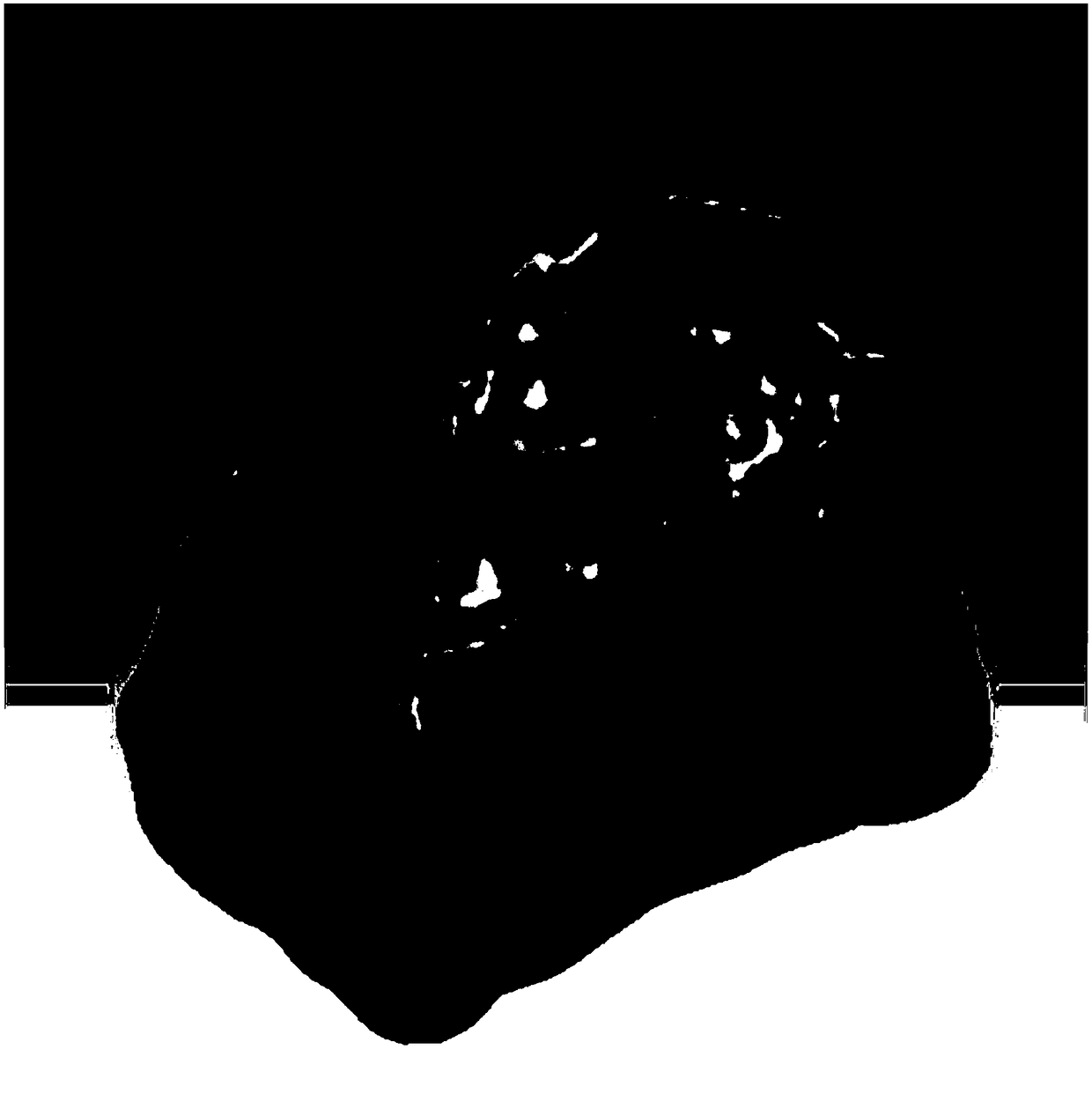

[0051] like Figure 1 to Figure 4 As shown, the present invention relates to a method for evaluating the overall surface roughness of three-dimensional irregular particles, which is used for scientific, objective and rapid evaluation of the overall surface roughness of irregular three-dimensional particles.

[0052] The main steps of a method for evaluating the overall surface roughness of three-dimensional irregular particles proposed by the present invention are as follows:

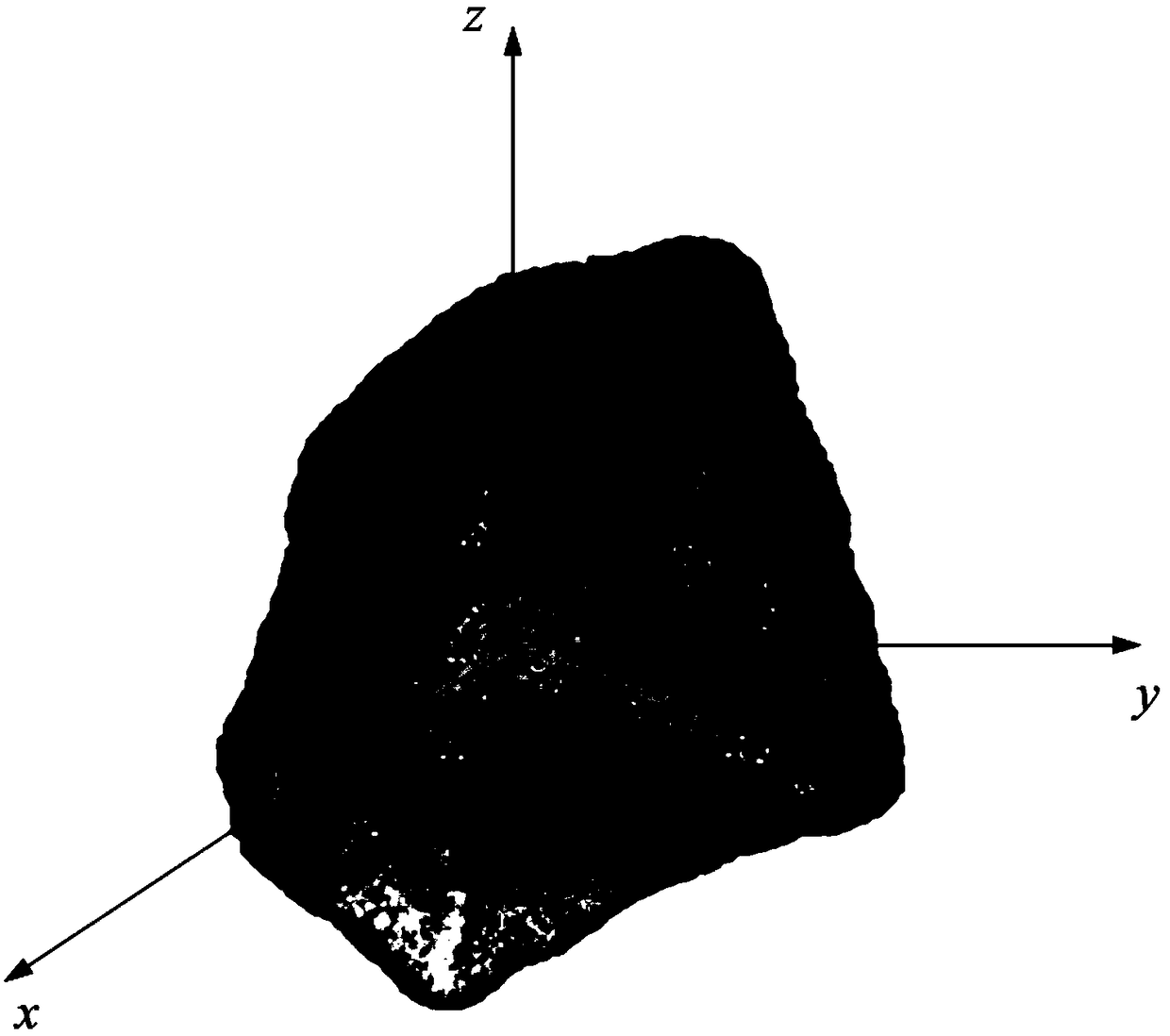

[0053] (1) Use a high-resolution 3D scanner to scan 3D irregular particles to obtain point cloud data on the surface of the particles (not less than 100,000 points per particle), such as figure 1 shown;

[0054] (2) The current roughness evaluation method can only measure and analyze the roughness of the local surface of the particle, but cannot evaluate the over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com