Surface defect detecting device for smooth long shaft member

A defect detection, long-axis technology, applied in the direction of material magnetic variables, etc., can solve the problems of rising product cost, missed inspection, fatigue and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments involved in the present invention will be described in further detail below in conjunction with the accompanying drawings.

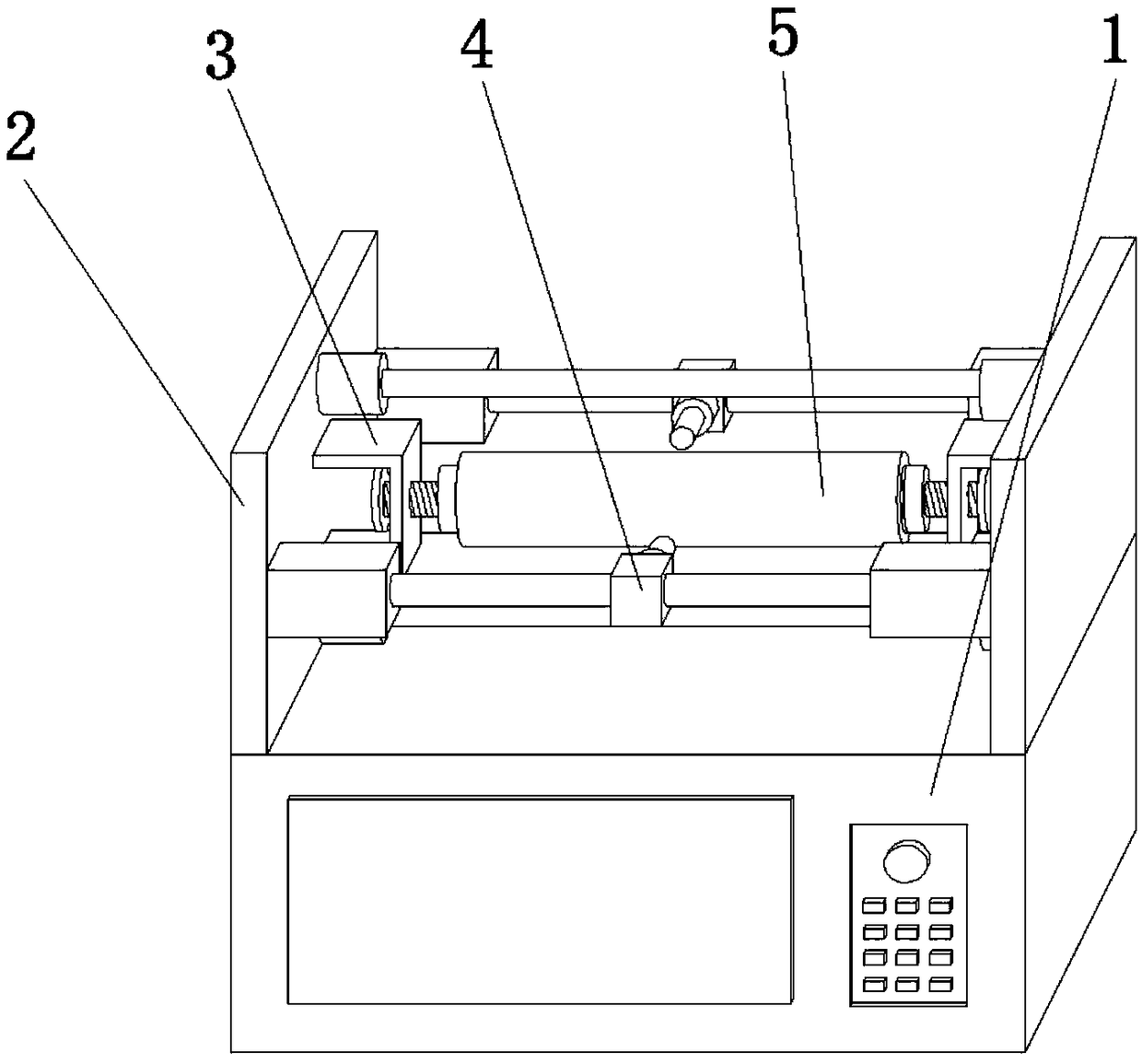

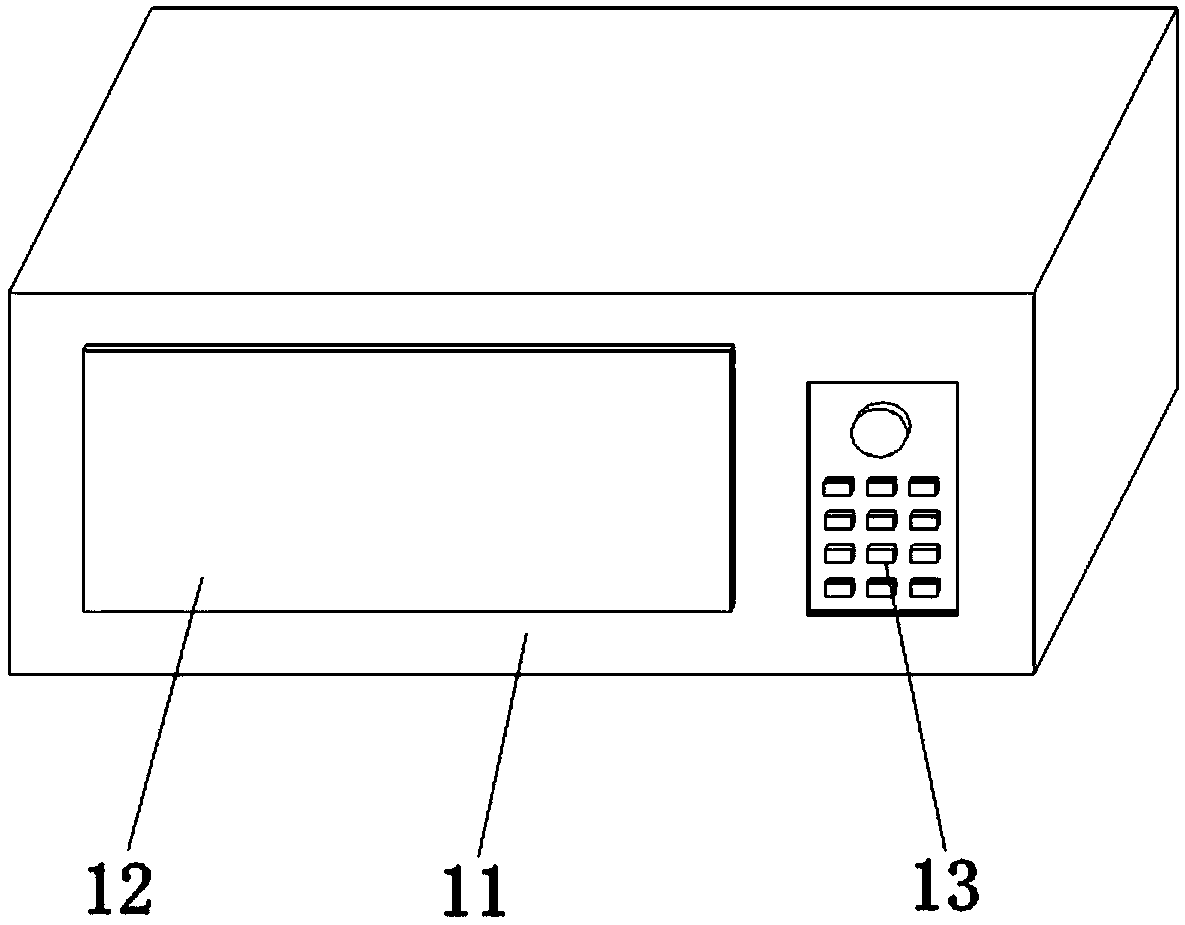

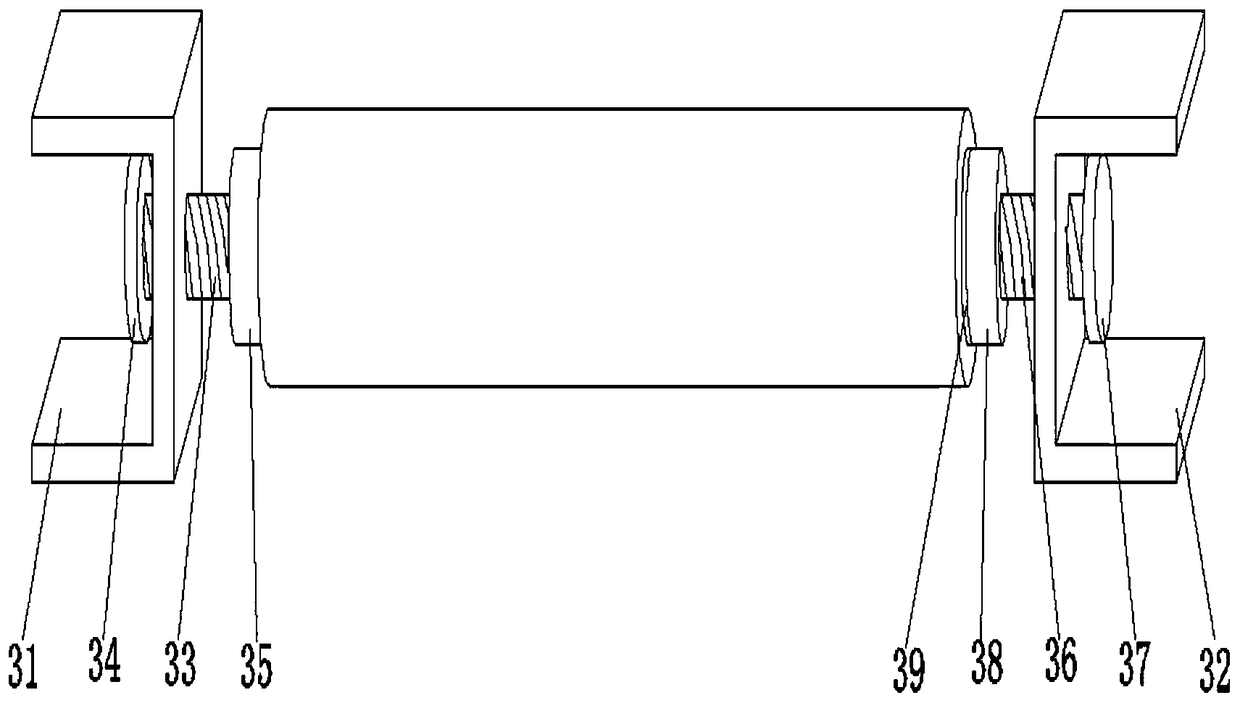

[0024] to combine Figure 1 to Figure 5 , a surface defect detection device for smooth long shaft parts, including a device body, the device body includes a control box 1, a support plate 2, a fixing mechanism 3 and a detection mechanism 4, a pair of support plates 2 are located on both sides of the top of the control box 1, fixed Both the mechanism 3 and the detection mechanism 4 are located above the control box 1, the fixing mechanism 3 is centrally located between a pair of support plates 2, and the detection mechanism 4 is also located between a pair of support plates 2; the control box 1 includes a box body 11, a liquid crystal Display screen 12, control panel 13 and controller, liquid crystal display screen 12 and control panel 13 are positioned at the front of box body 11, controller is positioned at the inside of box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com