Compressor stepless energy adjusting device and adjusting method and refrigerating system

An energy regulation and compressor technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems that the stepless capacity regulation technology cannot accurately match the changes, and the regulation response is not fast, so as to increase the processing difficulty and cost, Responsive, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

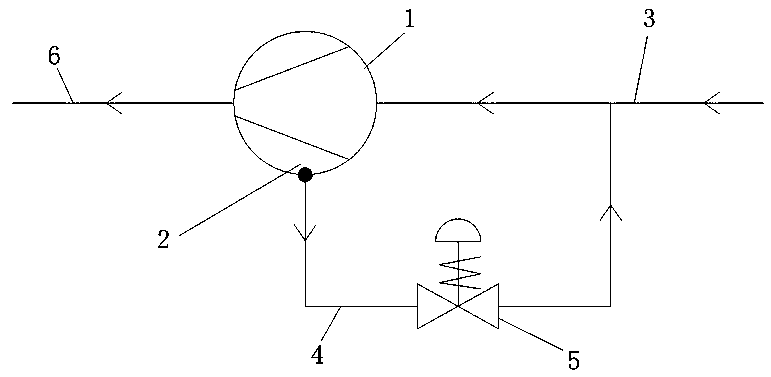

[0022] Such as figure 1 As shown, the present invention proposes an embodiment of a stepless energy adjustment device for a compressor, which includes: a screw compressor 1, a suction pipe 3 communicated with the suction port of the screw compressor, and a screw compressor exhaust Exhaust pipe 6 communicating with the mouth; bypass pipe 4 communicating the primary compression chamber 2 of the screw compressor 1 with the suction pipe 3 of the screw compressor, and a flow regulating valve 5 arranged on the bypass pipe 4 . In this embodiment, the flow regulating valve 5 adopts an ordinary electronic expansion valve; and the first compression chamber 2 of the screw compressor 1 is the closed space of the screw tooth groove where the first suction of the compressor ends. The stepless energy adjustment device also includes:

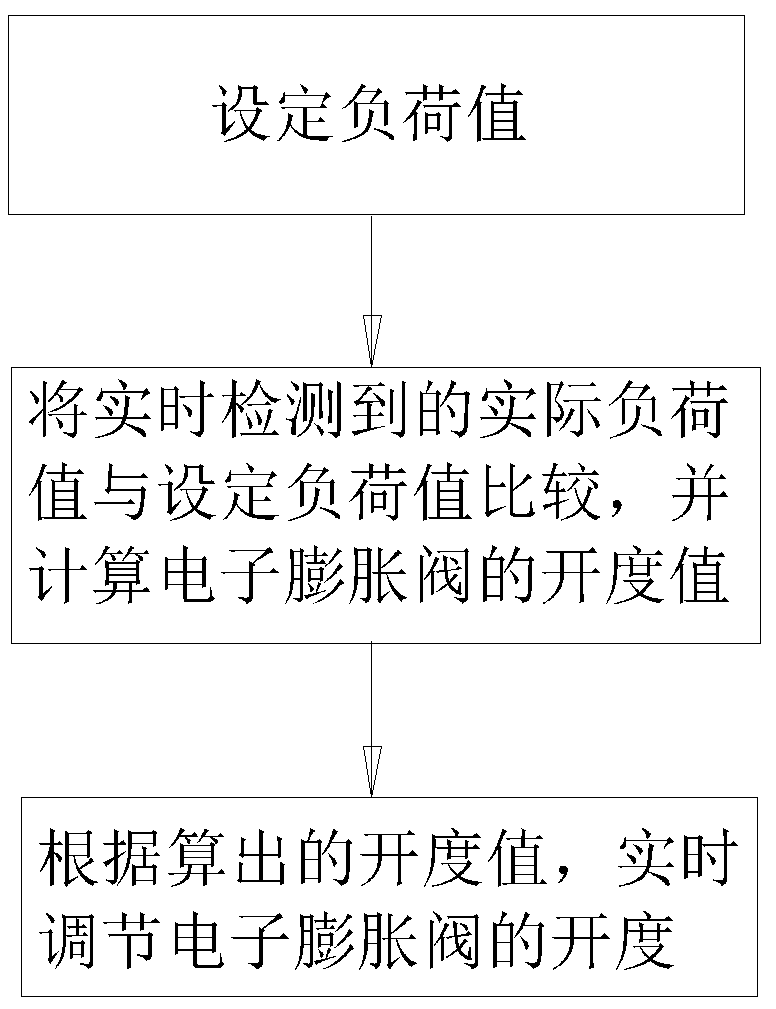

[0023] The sensor that collects the actual load value data of the refrigeration system, compares the actual load value with the load set value and calculates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com