Continuous drafter

A tractor and shuttle technology, applied in the field of transportation systems, can solve the problems of large wire rope pretension, large wire rope, and large floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

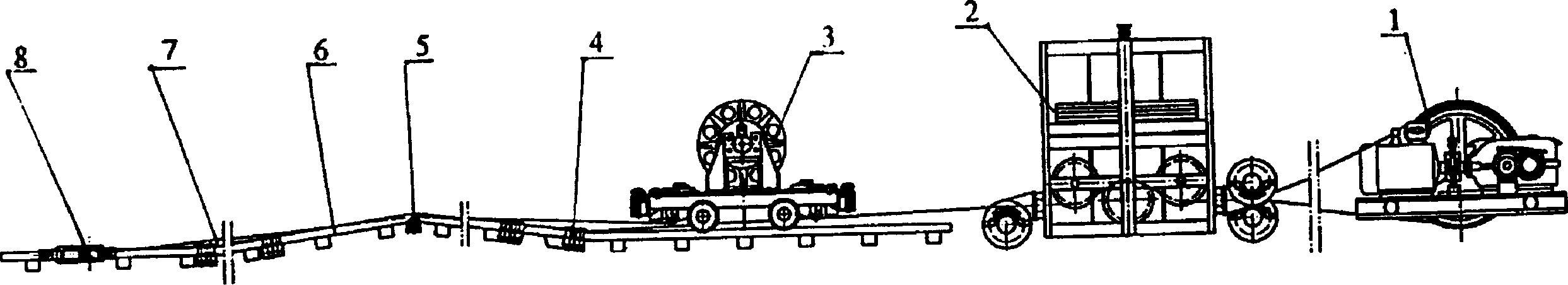

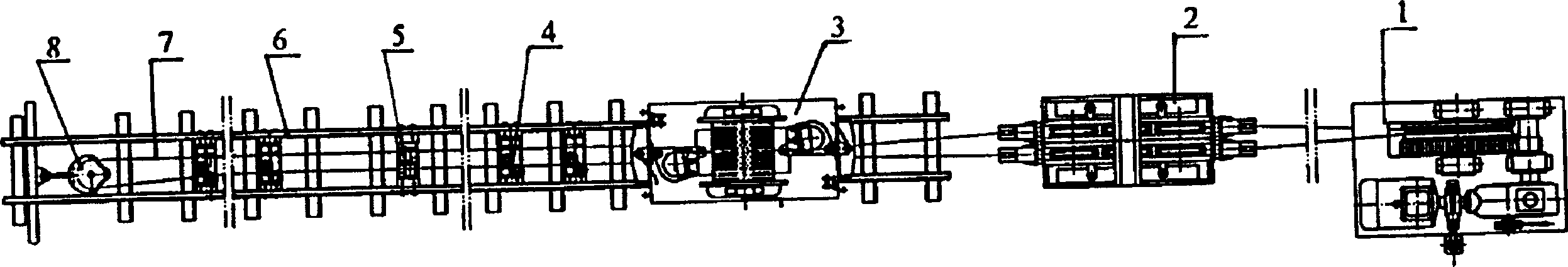

[0023] figure 1 versus figure 2 As shown, the present invention consists of an endless rope winch 1, a wire rope tensioning device 2, a shuttle car 3, a rope pressing device 4, a sheave 5, a rail 6, a wire rope 7, and a tail wheel 8. The wire rope tensioning device 2 is set on the endless rope In front of the rope winch 1, the tail wheel 8 is arranged at the end of the track 6, the rope pressing device 4 is arranged on the slope bottom track, the rope supporting device 5 is arranged on the slope top track, and the wire rope passes through the tensioning device 2.

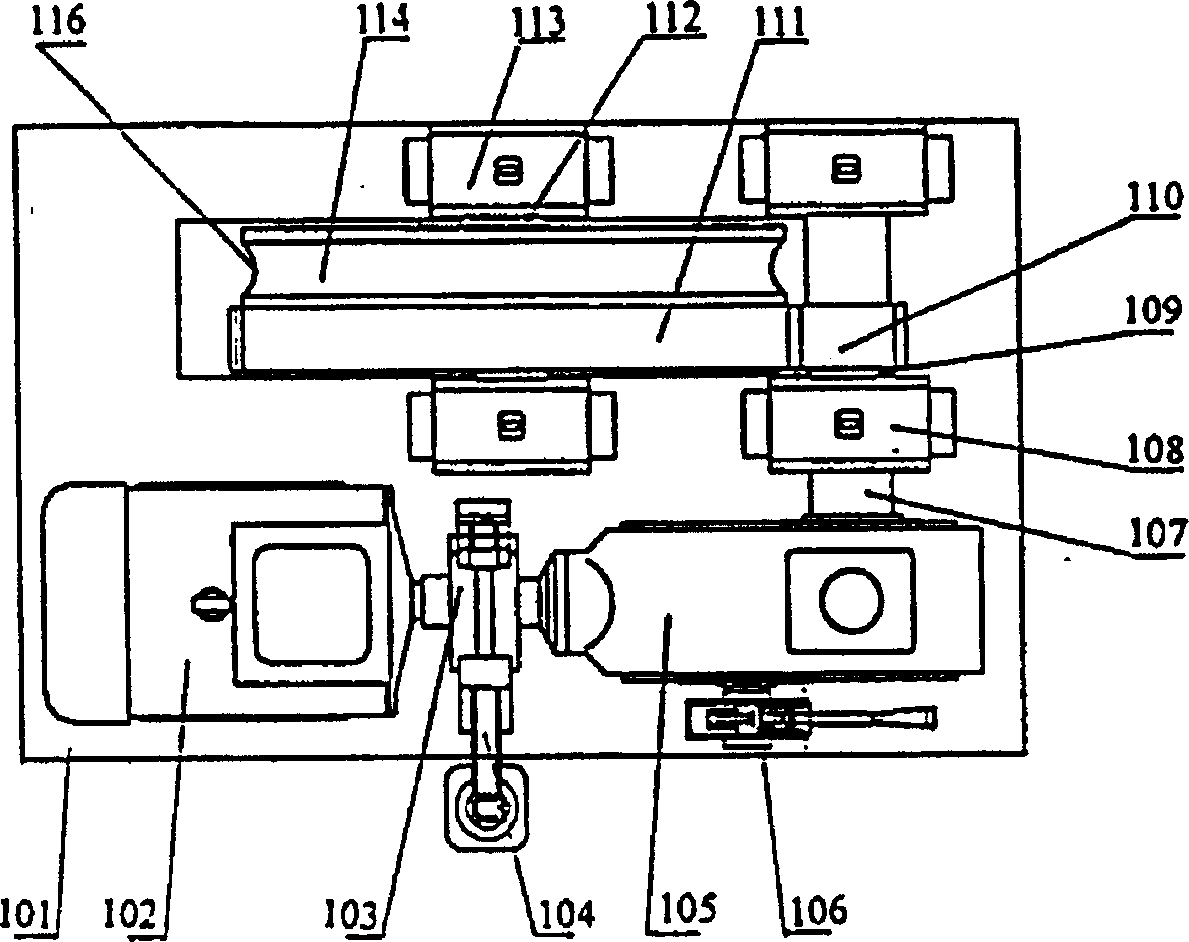

[0024] image 3 As shown, the endless rope winch 1 has a base 101 fixed on the ground. On one side of the base, an explosion-proof motor 102 and a reducer 105 are arranged along the length direction. An elastic pin coupling is used between the motor shaft and the input shaft of the reducer. 103 connection, that is, a connecting disc is fixed on each of the two shafts, and a number of nylon pins are used to connect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com