Planetary row hybrid power driving system and vehicle using the system thereof

A drive system and hybrid technology, which is applied to the arrangement of multiple different prime movers of hybrid vehicles, general power plants, and motor vehicles, etc., can solve problems such as obvious vibration and noise, reduce the number of torque transmission gear chains, avoid The effect of gear vibration and vibration noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] vehicle embodiment

[0041] This embodiment provides a vehicle, and the power system of the vehicle is a planetary row hybrid drive system. Since other components of the vehicle are not the focus of this application, the following will focus on the detailed description of the planetary row hybrid drive system.

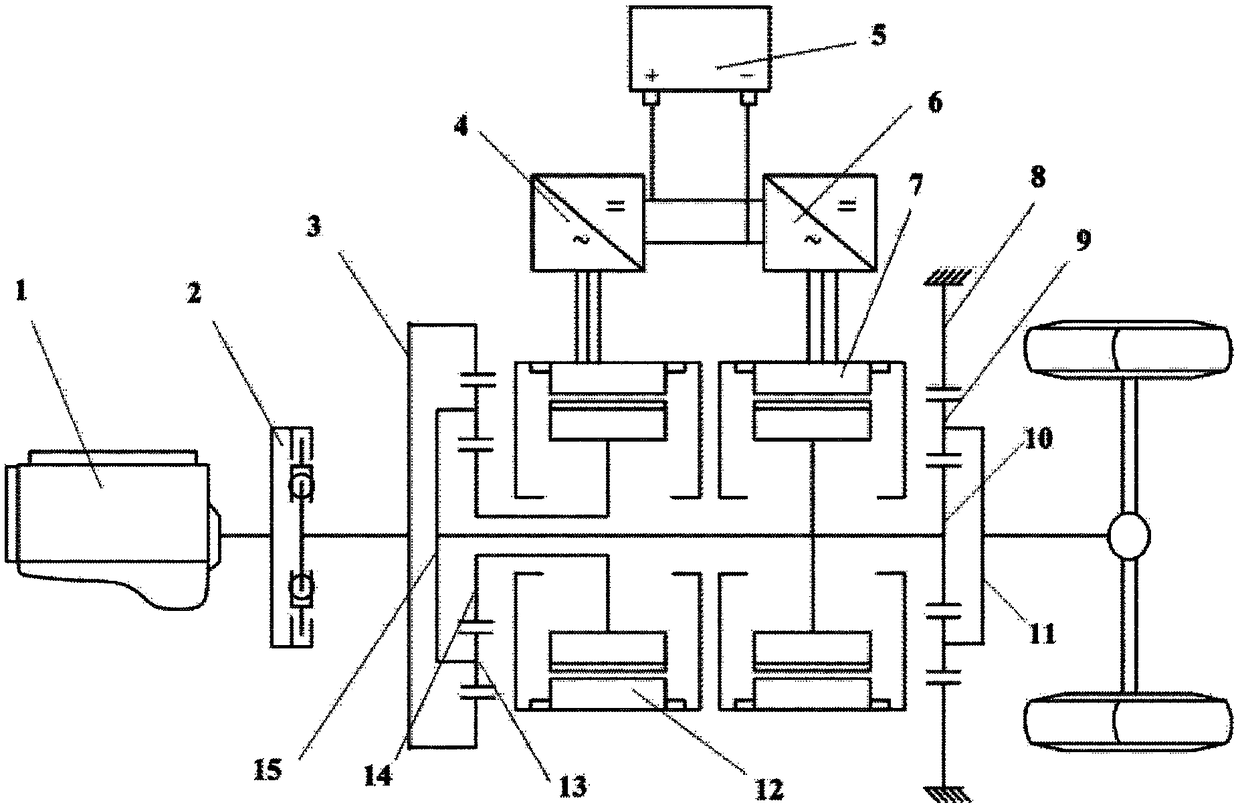

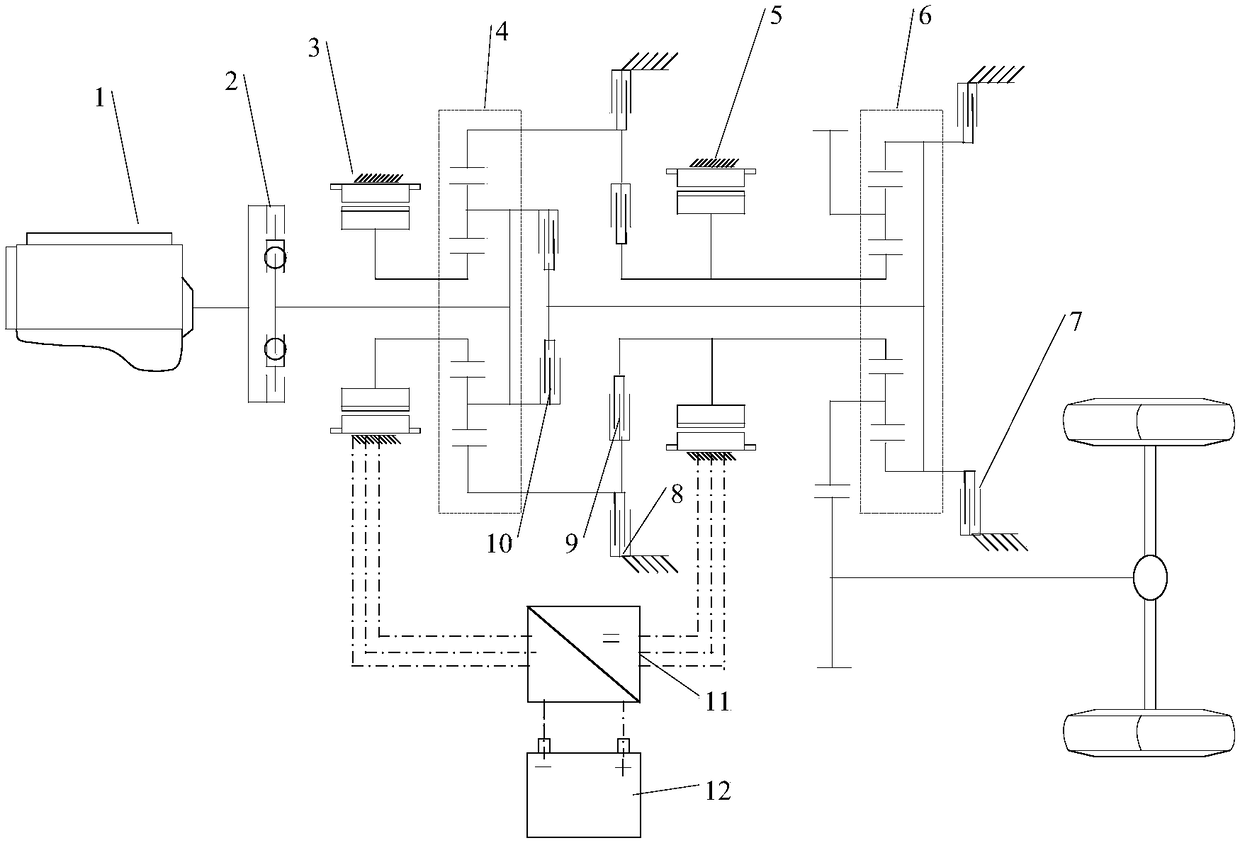

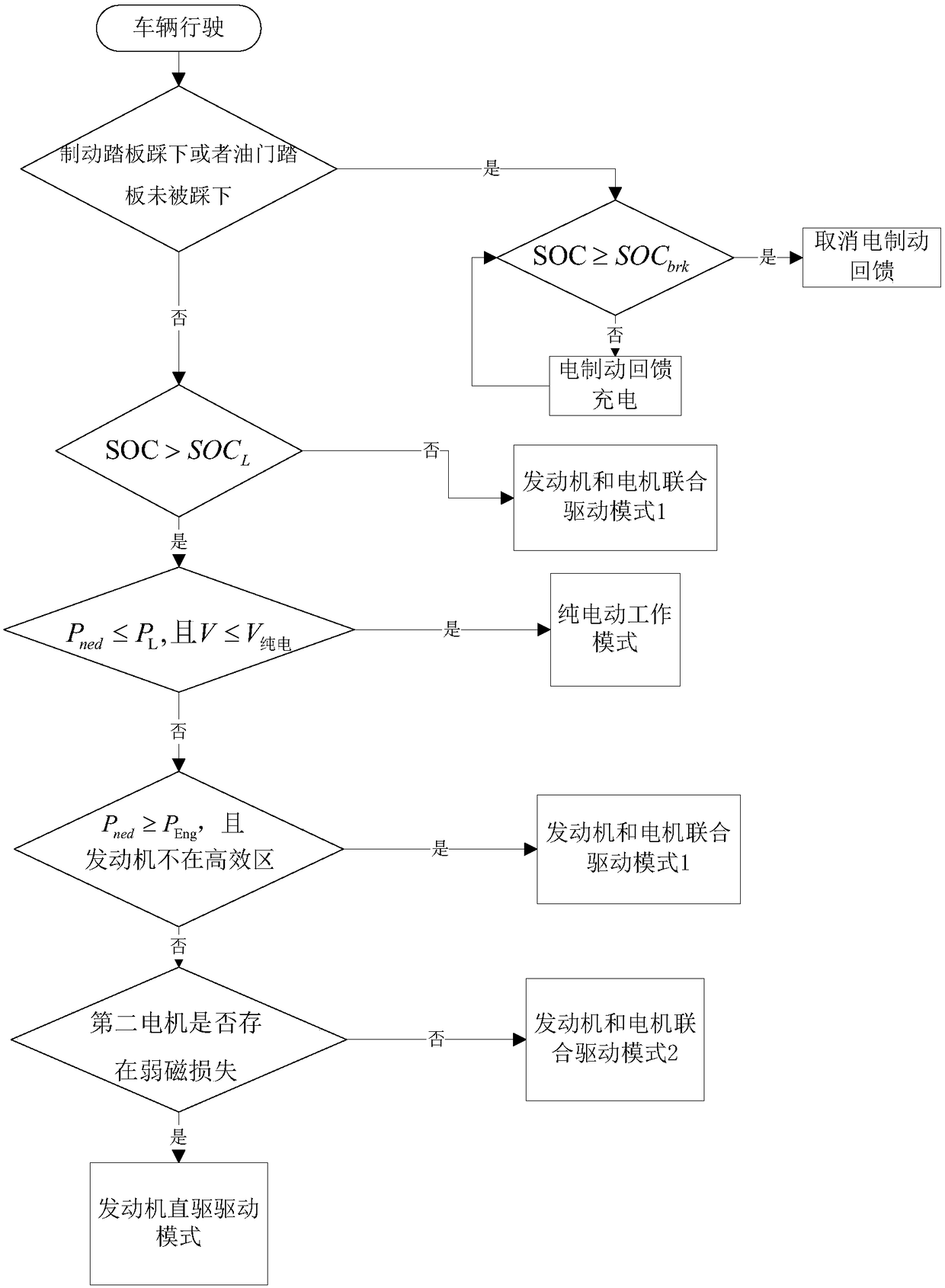

[0042] The planetary row hybrid drive system as a whole includes two parts, the front power structure and the rear power structure, such as figure 2 As shown, the front power structure includes the engine 1, the front planetary row 4 and the first motor 3, and the rear power structure includes the rear planetary row 6 and the system output shaft.

[0043] The front planetary row 4 includes three ends, which are respectively called the front first end, the front second end and the front third end. Since the three ends of the front planetary row 4 are the front sun gear, the front planetary carrier and the front ring gear respectively, Therefore, the front first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com