Production line of precast concrete members

A technology for producing assembly line and precast concrete, applied in the field of construction, can solve the problems of difficult to achieve efficient and convenient assembly line construction, difficult to vibrate concrete slabs, complex production equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

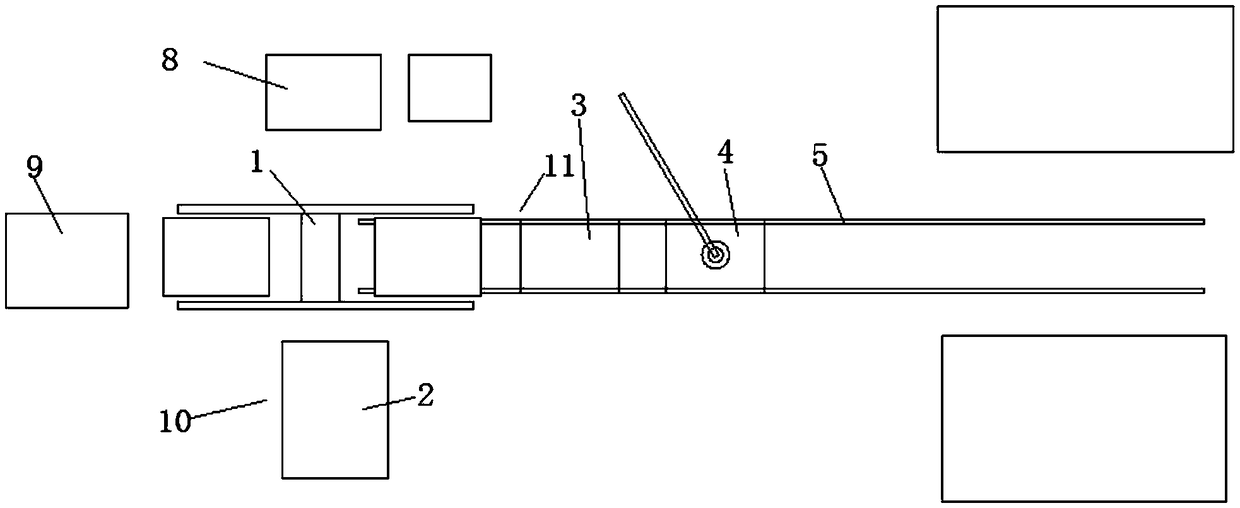

[0054] A production line for prefabricated concrete components, comprising a reversible concrete component pouring mold table 1, a liftable vibration table 2, a liftable temporary support device 3, a track 5, and a horizontally rotating cantilever crane 4;

[0055] Reversible concrete component pouring mold table 1 is provided with formwork preparation area 8, concrete feeding area 9, component vibration area 10, demoulding area 11, formwork preparation area 8, concrete feeding area 9, and component vibration area 10. , The demoulding area 11 is distributed in the counterclockwise direction around the reversible concrete component pouring mold table 1;

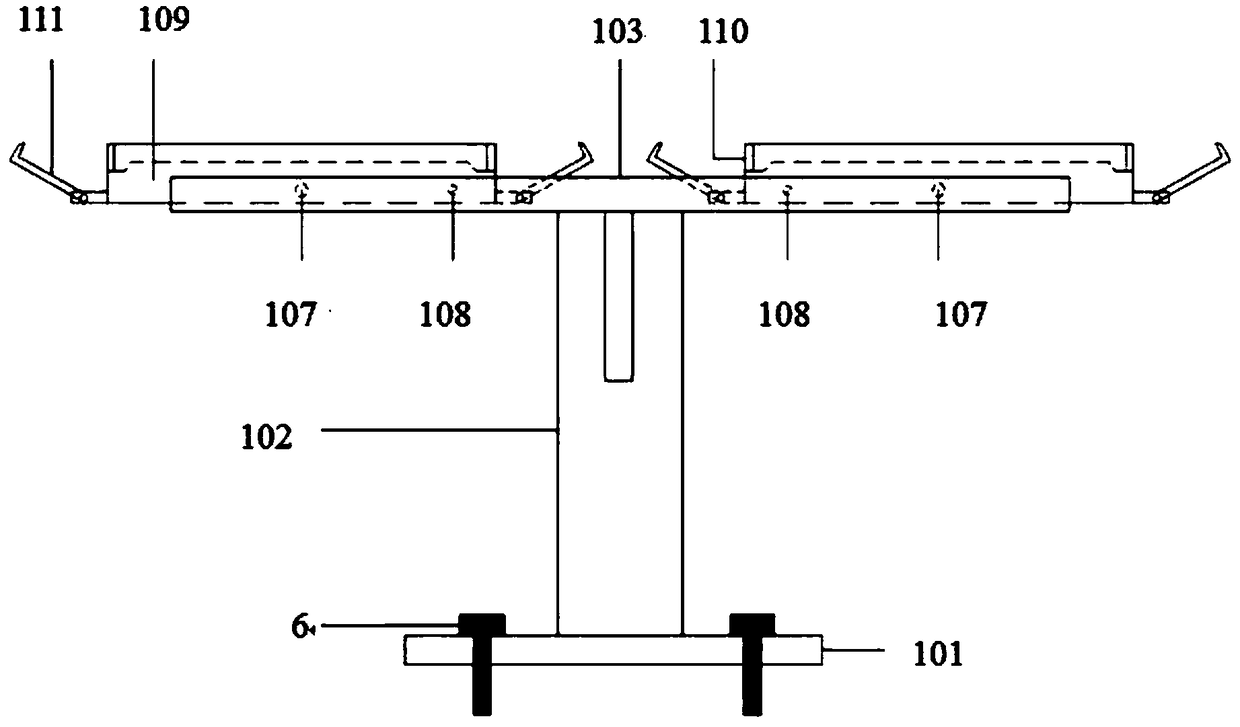

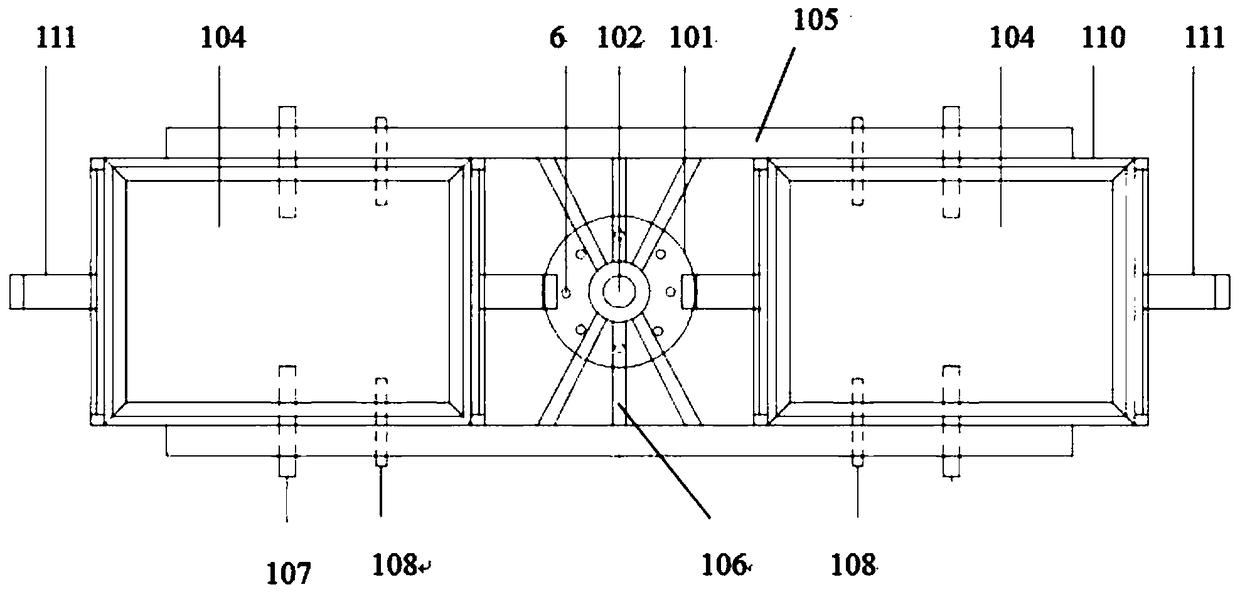

[0056] The reversible concrete component pouring formwork 1 includes the pouring formwork bottom plate 101, the vertical rotating shaft 102, the formwork rotating steel frame 103, and the rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com