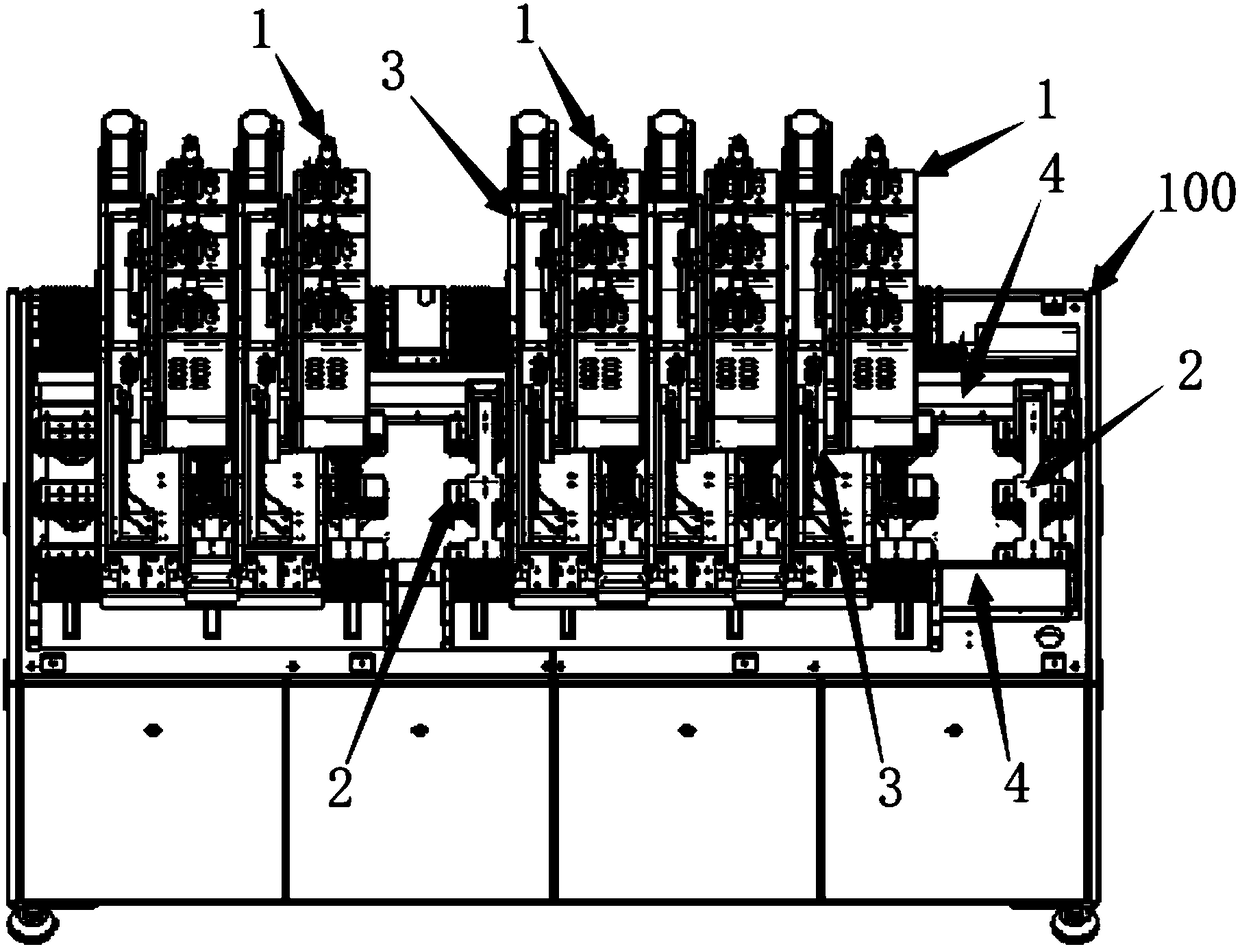

Polishing machine

The technology of a polishing machine and a polishing device, which is applied in the field of polishing machines, can solve problems such as the inability of polishing machines to polish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0056] Further, see Figure 5 to Figure 8 , as a specific embodiment of the jig device provided by the present invention, the water barrier assembly includes: a second sealing sleeve 26 , a second snap ring (not shown) and a second sealing ring 28 .

[0057] The second sealing sleeve 26 is sleeved on the outside of the connection between the base 25 and the first sealing sleeve 22 , and the inner wall of the second sealing sleeve 26 is formed with a second locking groove 261 and a second locking groove 261 ringed on the outside of the first sealing sleeve 22 . The flange 262 , the second locking groove 261 and the second flange 262 respectively extend along the circumferential direction of the second sealing sleeve 26 ;

[0058] The second snap ring is set in the second slot 261; and

[0059] The second sealing ring 28 is disposed between the first sealing sleeve 22 and the second sealing sleeve 26 , and the end surfaces of the second sealing ring 28 abut against the second f...

Embodiment approach

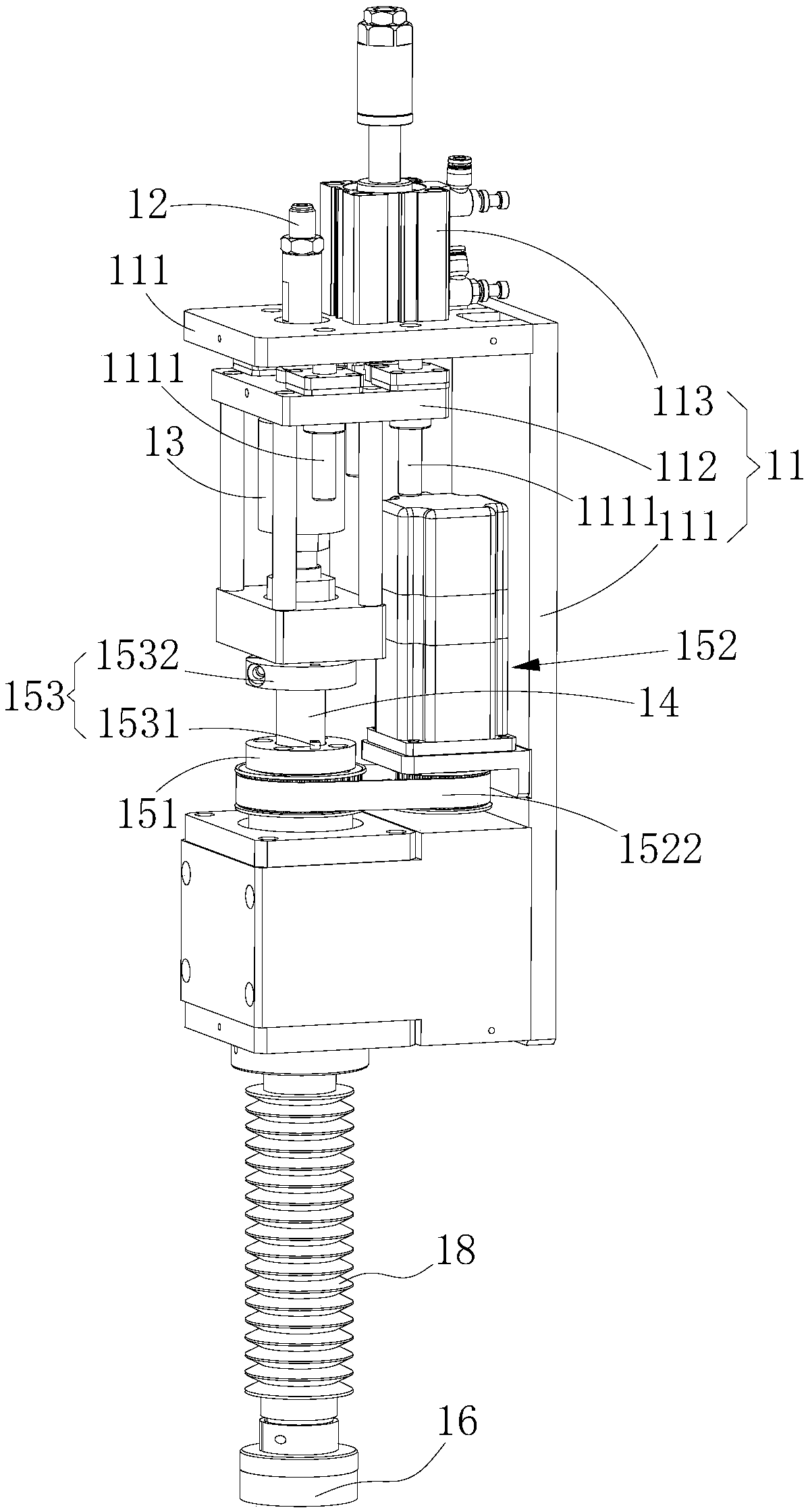

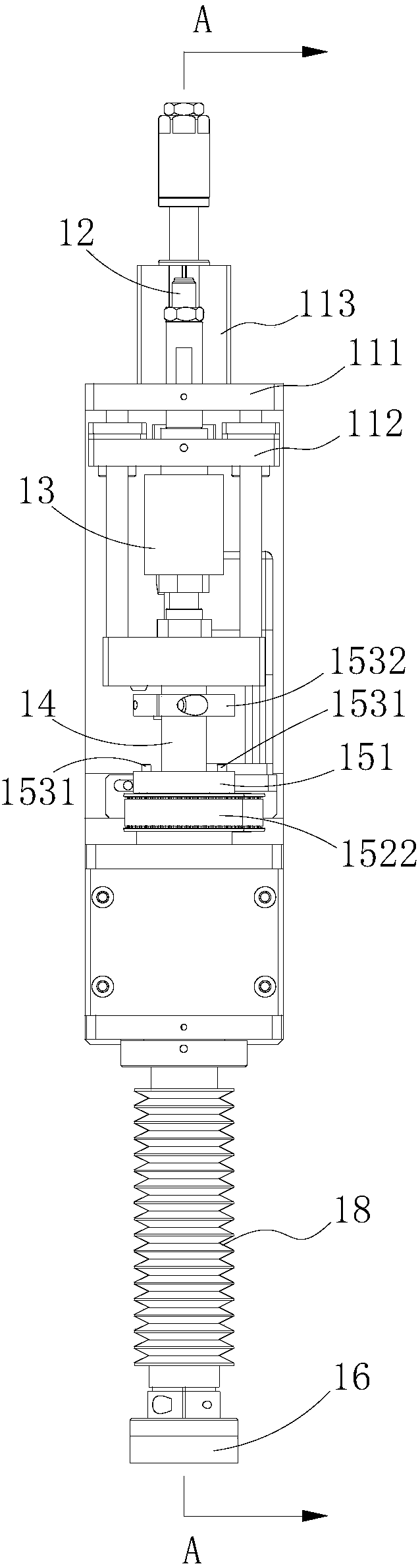

[0144] Further, see Figure 10 to Figure 12 As a specific embodiment of the angle adjustment lifting device 3 provided by the present invention, the connecting structure includes a roller 3311 arranged on the connecting rod 331 and a guide provided on the traction member 3323 for accommodating the roller 3311 and allowing the roller 3311 to slide The groove 33231 and the guide groove 33231 extend in directions perpendicular to the rotating shaft 3341 and the guide rail 3321 respectively.

[0145] In this embodiment, the connecting rod 331 is provided with a roller 3311, and the traction member 3323 is provided with a guide groove 33231. The guide groove 33231 is used to accommodate the roller 3311 and allow the roller 3311 to move in a direction perpendicular to the rotating shaft 3341 and the guide rail 3321 respectively. move. In this way, when the connecting rod 331 is moving, the connecting rod 331 will approach or move away from the guide rail 3321 in directions perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com