Device for preventing crystallization blockage of ammonia desulfurization tower

An ammonia desulfurization and desulfurization tower technology, applied in the field of ammonia desulfurization towers, can solve the problems of increased system resistance, unbalanced circulating liquid water, incomplete precipitation and crystallization, etc., and achieves the effect of reducing reuse and reducing discharge pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

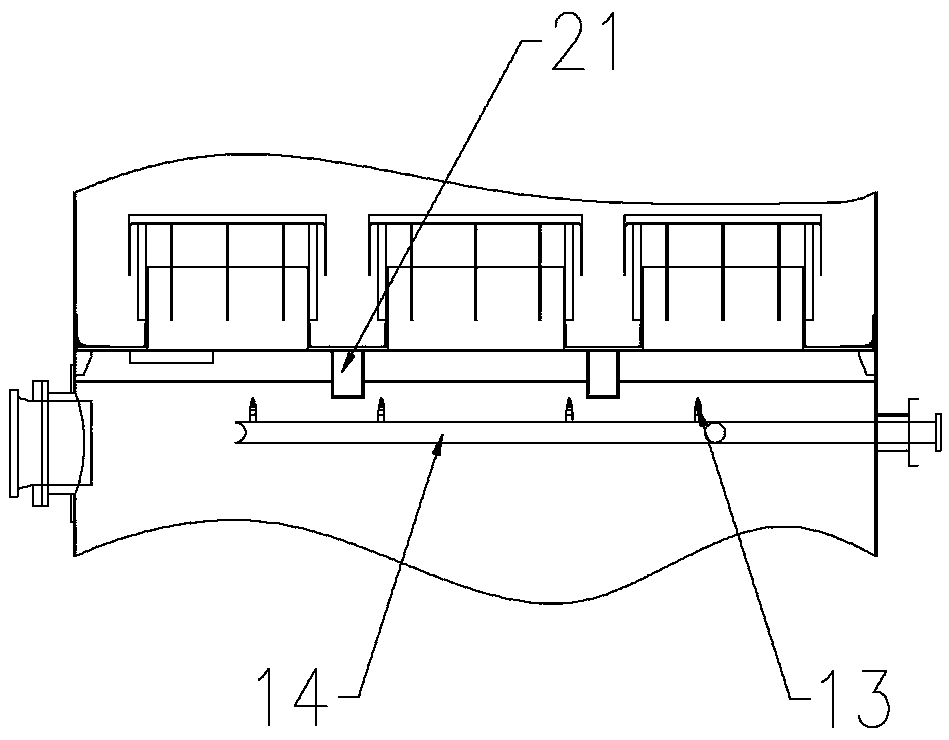

[0034] Such as figure 1 , figure 2 Shown, a kind of device that prevents the crystallization blockage of ammonia method desulfurization tower, the bottom of this desulfurization tower 1 is absorption liquid section 15, and the top of absorption liquid section 15 is concentration section 16, and the top of concentration section 16 is absorption section 17, absorbs The upper part of the section 17 is the water washing demister section 27, and the upper part of the water washing demist section 27 is the demister section 25, and a closed tower inner baffle 11 is arranged between the absorption liquid section 15 and the concentration section 16, and the tower inner baffle 11 It is the separation plate between the absorption liquid section 15 and the concentration section 16, and the concentration lifter 10 is arranged between the concentration section 16 and the absorption section 17, and the concentration lifter 10 belongs to the separation plate between the concentration section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com