Sealing performance detection test bench for integrated fire hydrant water pressure monitoring instrument

A sealing detection and fire hydrant technology, which is applied in the direction of measuring the rate of increase and deceleration of the fluid, and using the liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of low work efficiency and affecting production efficiency, so as to improve efficiency and test The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

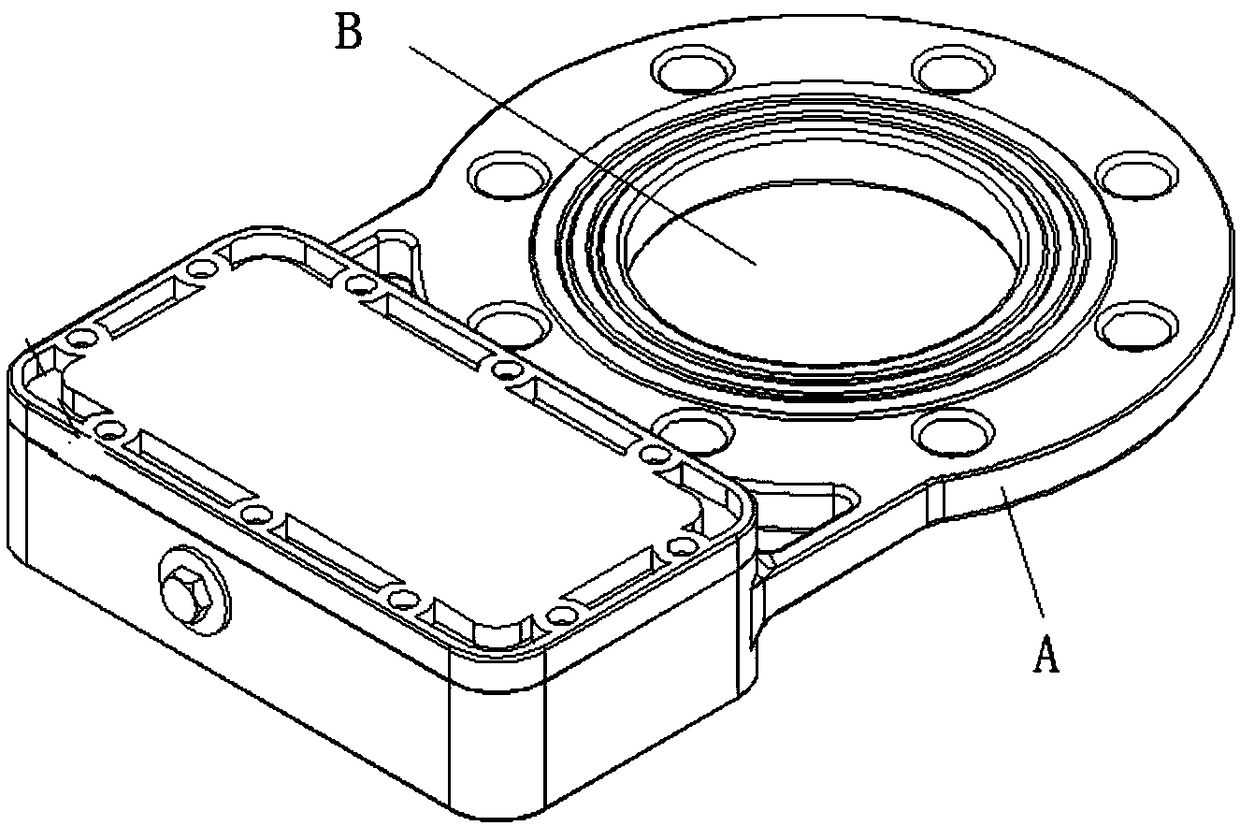

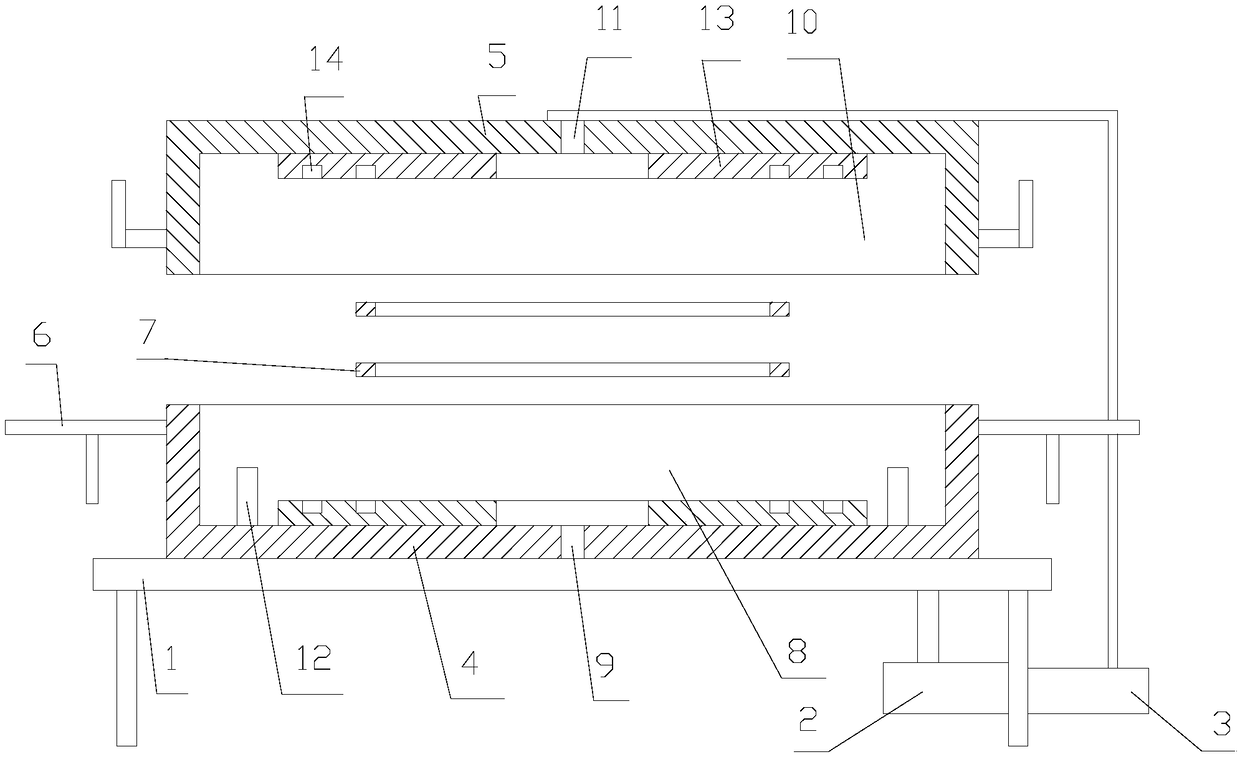

[0019] refer to figure 1 , a leak detection test bench for an integrated fire hydrant water pressure monitor proposed by the present invention, including a bracket 1, a water pump 2, a booster pump 3, a support 4, a cover plate 5, a fastener 6, and two sealing rings 7. The support member 4 is installed on the bracket 1, and the support member 4 is provided with a first accommodation tank 8 and a water outlet hole 9. The water outlet hole 9 communicates with the first accommodation tank 8, and the water outlet hole 9 communicates with the water pump 2; The pressure pump 3 is connected; the cover plate 5 is provided with a second storage tank 10 and a water inlet hole 11, and the second storage tank 10 is matched with the first storage tank 8; the water inlet hole 11 is connected with the second storage tank 10, and the water inlet The hole 11 communicates with the booster pump 3; the fastener 6 is used to connect the cover plate 5 and the support member 4; two sealing rings 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com