An ultrasonic-based air foil bearing air film thickness measurement system and method

A foil bearing and thickness measurement technology, which is applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problem of not being able to obtain the value of the gas film thickness, and achieve the effect of improving application capabilities and measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the present invention, such as the structure of each part involved, the mutual position and assembly relationship between each part, the function and specific working principle of each part, etc., will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. However, it can be understood that the following specific embodiments are only preferred technical solutions of the present invention, and should not be construed as limiting the present invention.

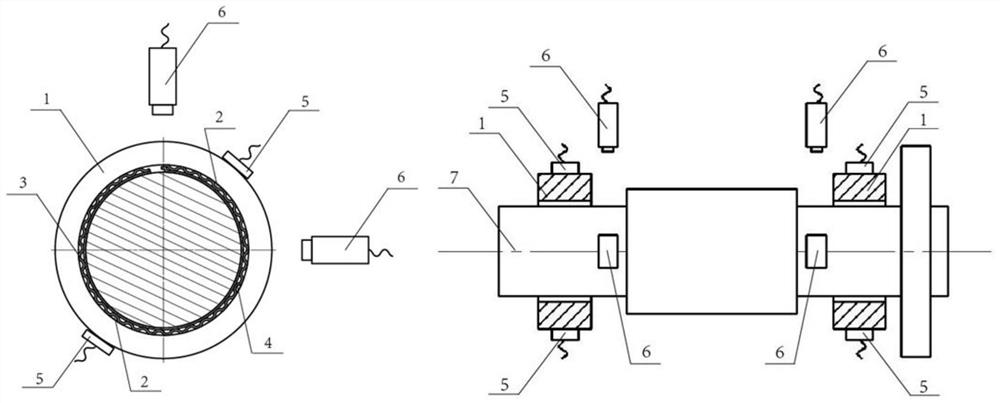

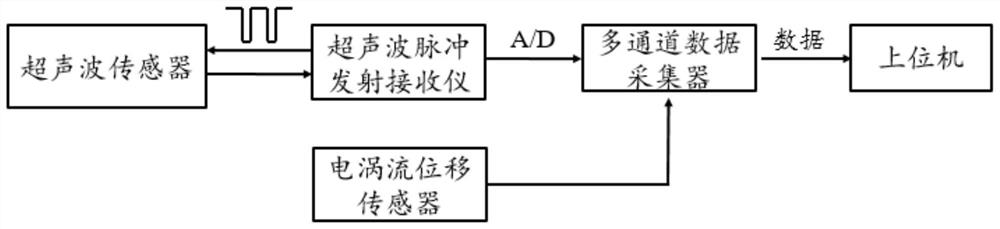

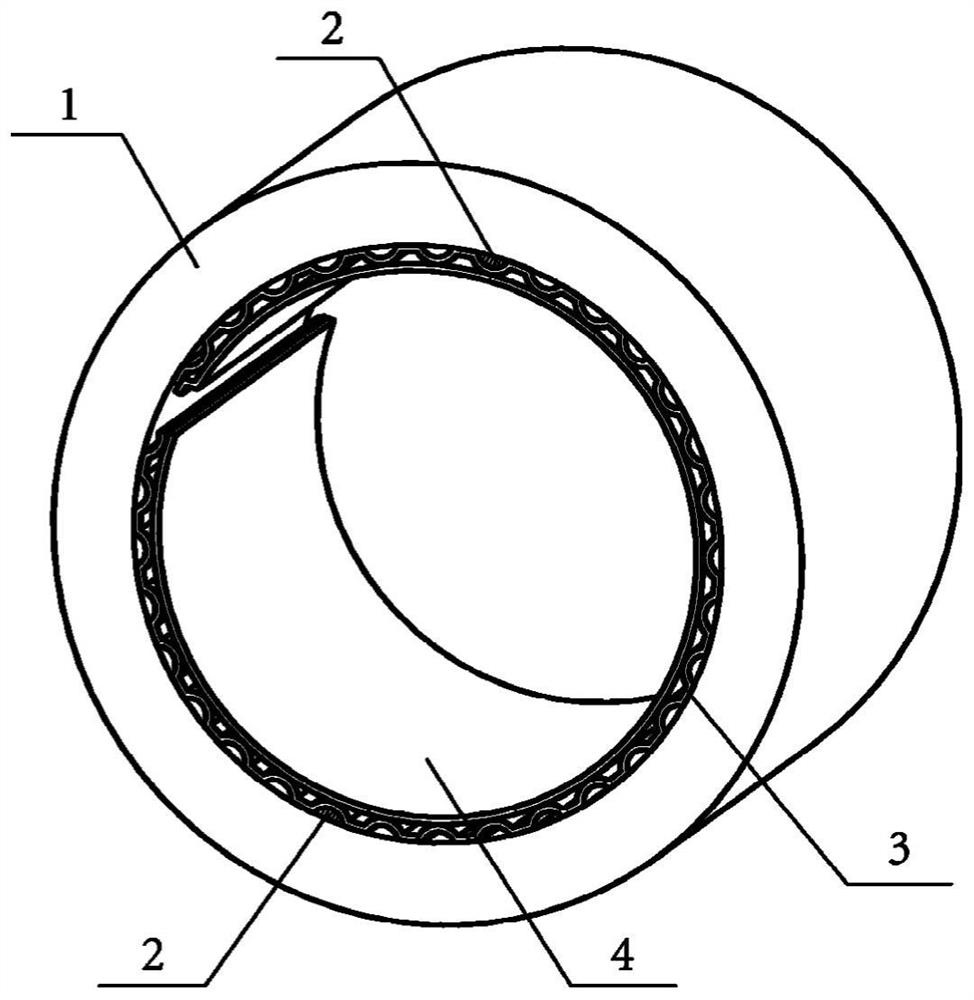

[0029] Such as Figure 1-2 As shown, a system and method for measuring the air film thickness of an air foil bearing based on ultrasonic waves, specifically including a bearing sleeve 1, a hydrogel layer 2, a corrugated foil 3, a top foil 4, an ultrasonic sensor 5, and two eddy current sensors 6 , Rotor 7, ultrasonic pulse transmitting and receiving instrument, multi-channel data acquisition instrument, upper computer.

[0030] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com