Longitudinal coaxial gear-shiftable electrically driven bridge reduction gearbox assembly

An electric drive, coaxial technology, applied in the transmission box, axle, transmission device, etc., can solve the problems of low efficiency and high cost of the power transmission system, and achieve the effect of reducing system cost, low cost and high technology maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

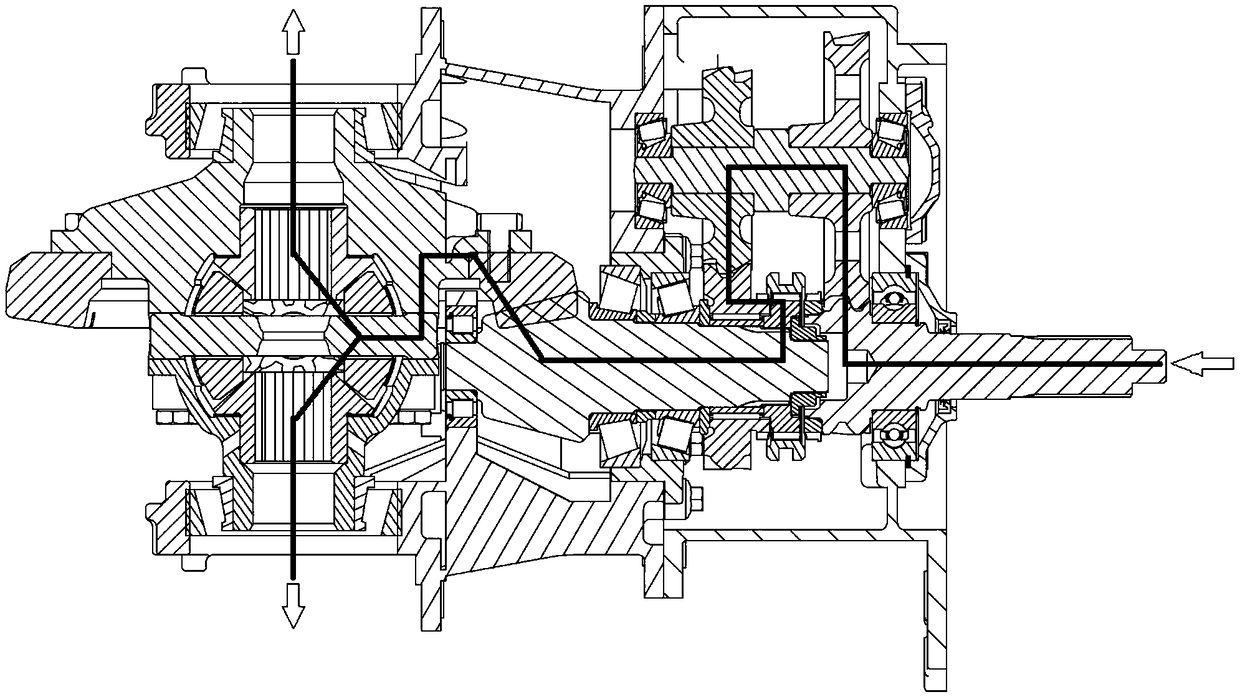

[0015] see Figure 1 to Figure 3 , a vertical coaxial shiftable electric drive axle gearbox assembly, including a motor, a shaft assembly 1, an intermediate shaft assembly 2, a main cone shaft assembly 3 and a differential assembly 4. The countershaft assembly 2 includes a countershaft 15, a countershaft constant mesh gear 12 and a countershaft low speed gear 13; On the shaft 15, namely the inner hole of the countershaft constant meshing gear 12 and the inner hole of the countershaft low speed gear 13 are interference fit with the countershaft 15. The main bevel shaft assembly 3 includes a driving bevel gear 10, a main bevel shaft low gear 14 and a fixed tooth seat 9, and the main bevel low gear 14 is connected with the driving bevel gear 10 through a needle bearing, so The above-mentioned fixed gear seat 9 is fixed on the driving b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com