Combined type blade profile probe measuring method for inlet airflow parameters of adjustable stationary blade

An airflow parameter and probe measurement technology, which is applied in non-variable pumps, pump control, machines/engines, etc., can solve the problem that the vane-shaped probe on the stator blade cannot adapt to the measurement of airflow parameters in all working conditions, and achieve high Promote the application value, easy to implement, and improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

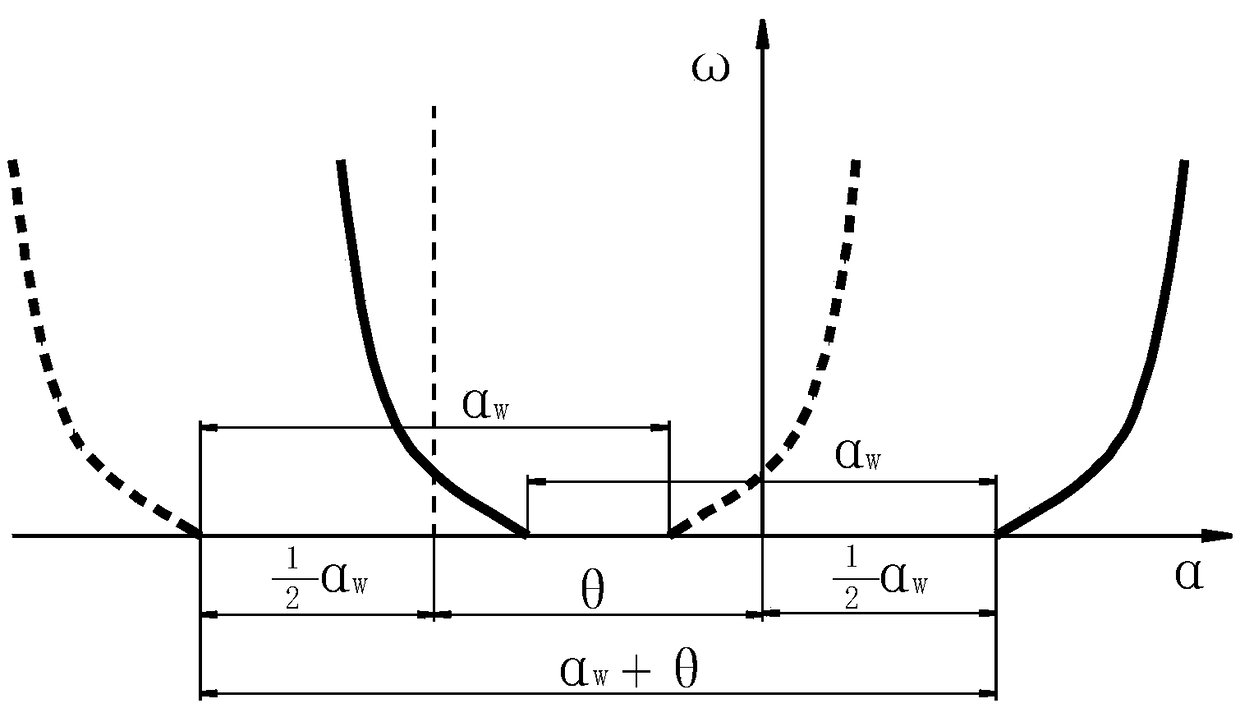

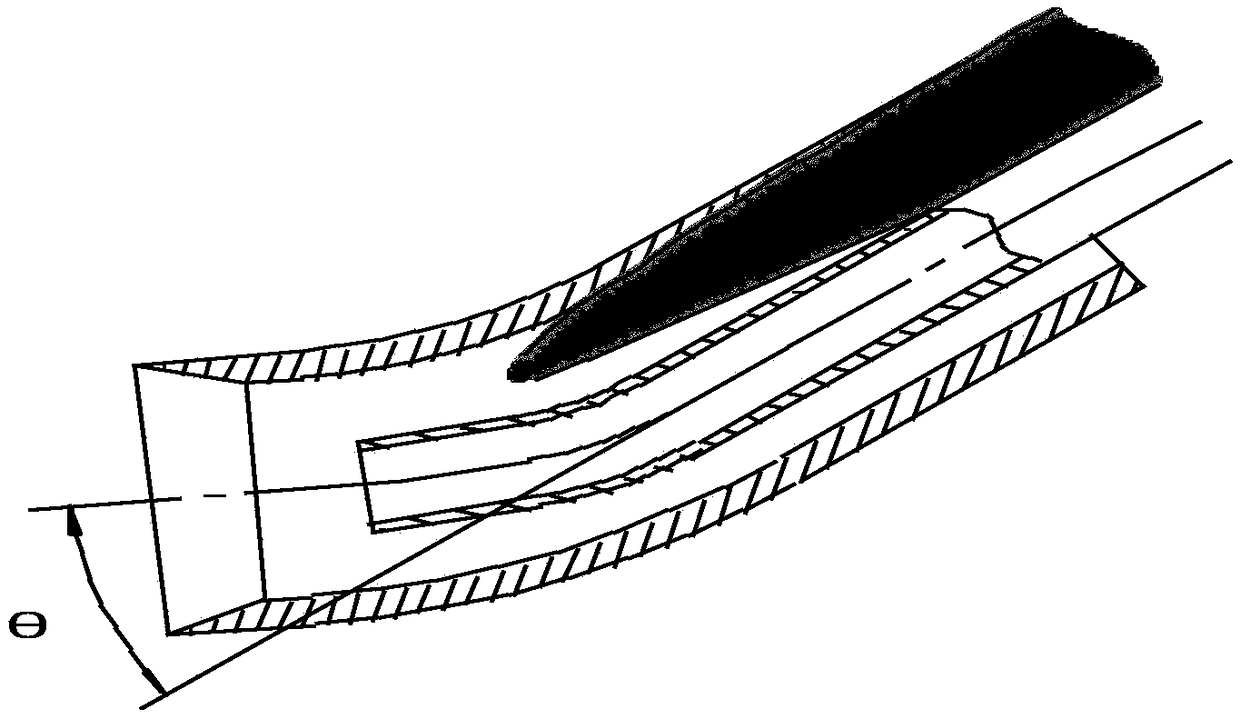

[0016] Retain conventional airfoil probes as high-speed airfoil probes for the measurement of airflow parameters between compressor stages with a relative conversion speed of more than 90%, and deflected airfoil probes as low-speed airfoil probes for relatively Convert the airflow parameter measurement between compressor stages at and below the speed of 85%, so as to increase the total insensitive angle range of the blade probe, so that the airflow parameters of the adjustable vane inlet of the compressor can meet the measurement requirements in the entire performance recording speed range Accuracy requirements. The radial position and the number of measuring points of the conventional airfoil probe and the deflected airfoil probe are exactly the same, that is, there are two measuring points of the airfoil probe with different circumferential positions at the same radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com