Cloth rack

A cloth and fixing rack technology, applied in the field of cloth racks, can solve the problem of not being able to slide freely, only one cloth reel can be installed, strengthening and other problems, so as to ensure the placement temperature, improve the sensitivity, and prevent the temperature from being too high or too low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

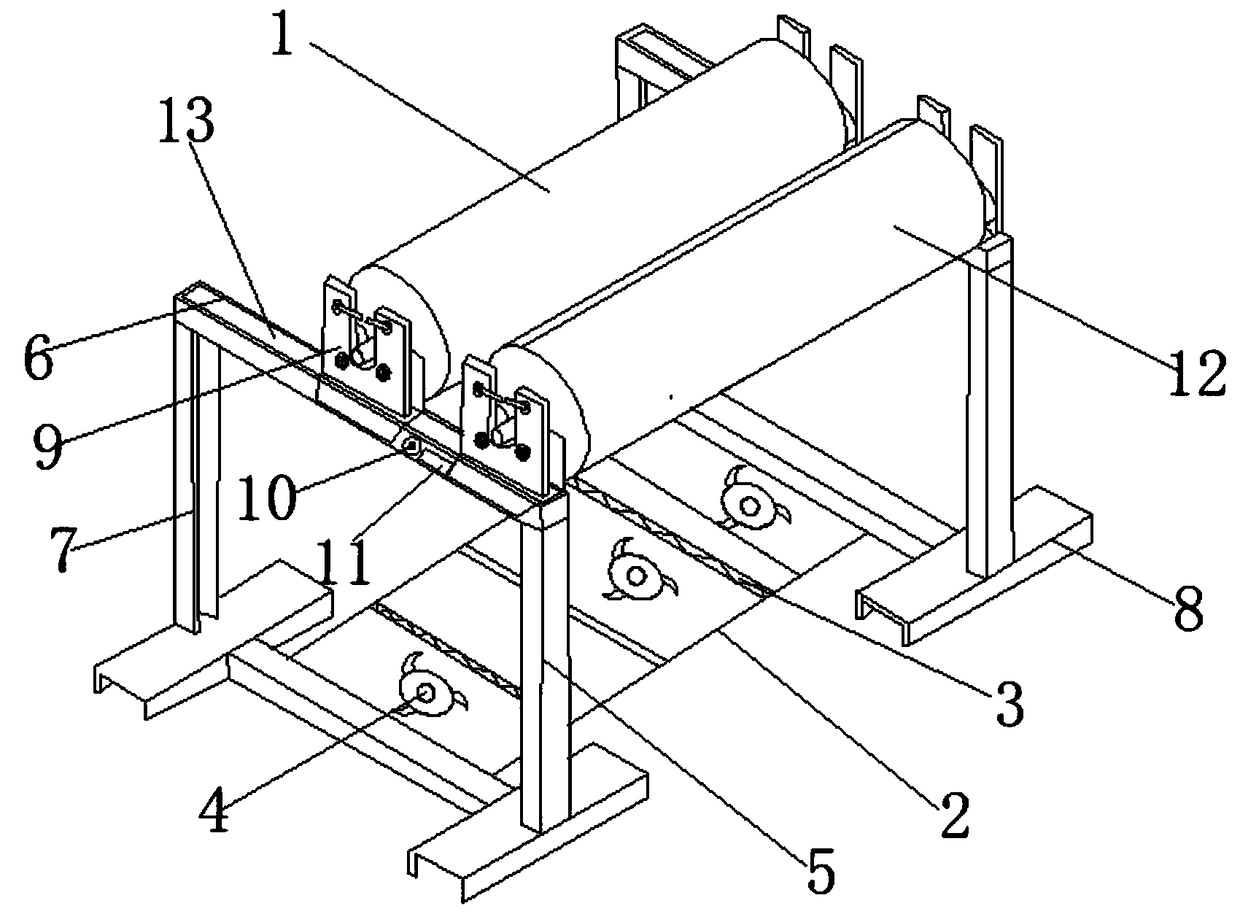

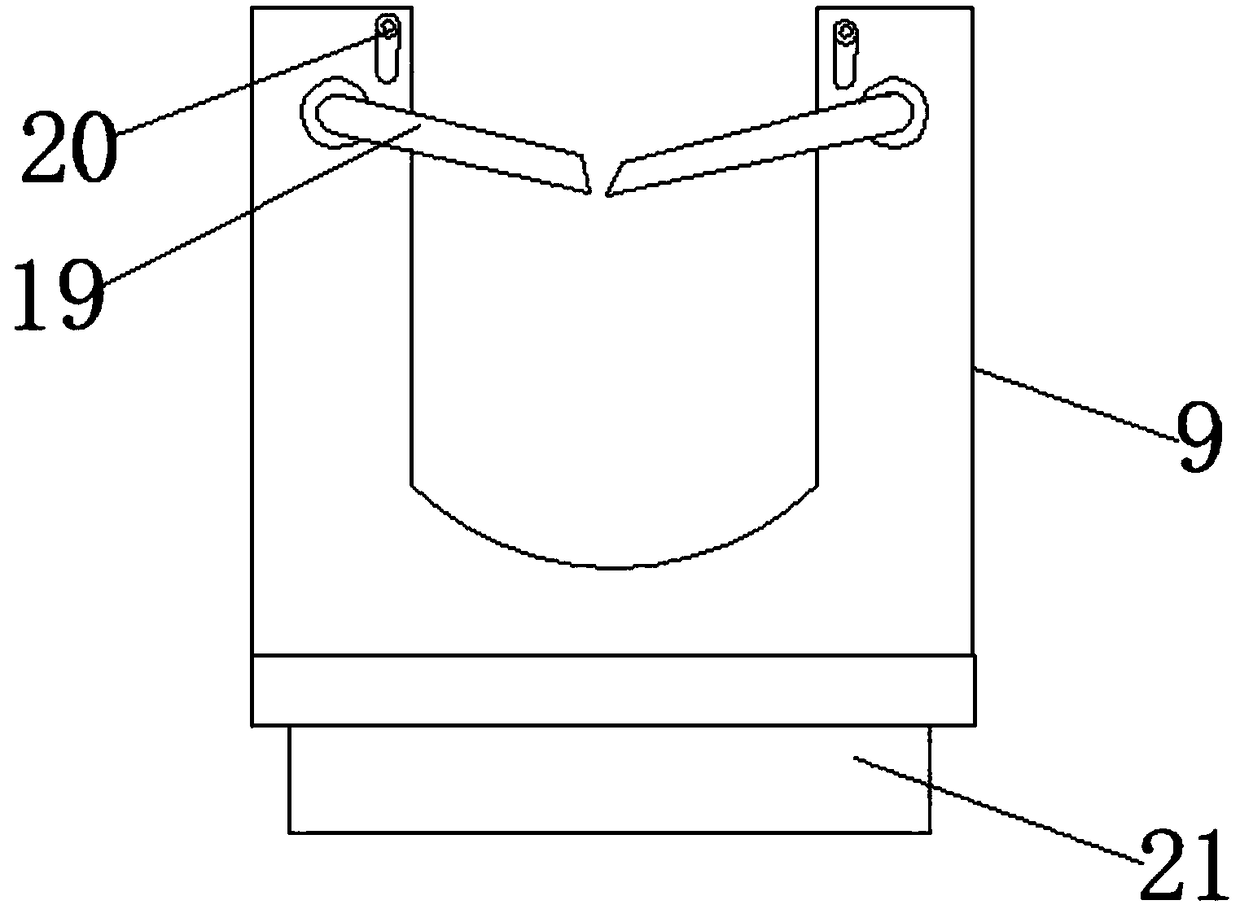

[0028] Such as Figure 1-4 As shown, a cloth rack includes a cloth rack main body 1, and the cloth rack main body 1 includes a base plate 2, a fan 4, a heating and cooling wire 3, a fixing frame 5 and a cloth reel 12, and two equidistant installations are arranged on the base plate 2 The heat radiation wire 3 is fixedly installed with a fan 4 on both sides of the heat radiation wire 3, and the interlayer of the substrate 2 is filled with water. Fixed vertical bar 7 is welded on the two ends of fixed horizontal bar 6, and I-shaped steel 8 is welded on the lower end of fixed vertical bar 7, and the upper surface of described fixed horizontal bar 6 is laid with slide rail 13, and described slide rail 13 is installed with Connecting frame 9, described connecting frame 9 comprises gear rod 19, fixed rod 20 and slide block 21, and the middle of described connecting frame 9 leaves groove, and the upper end both sides of groove is movably installed with gear rod 19, and described gear...

Embodiment 2

[0031] Such as Figure 1-4 As shown, a cloth rack includes a cloth rack main body 1, and the cloth rack main body 1 includes a base plate 2, a fan 4, a heating and cooling wire 3, a fixing frame 5 and a cloth reel 12, and two equidistant installations are arranged on the base plate 2 Heating the heat dissipation wire 3, and fans 4 are fixedly installed on both sides of the heating heat dissipation wire 3, and the interlayer of the substrate 2 is filled with water,

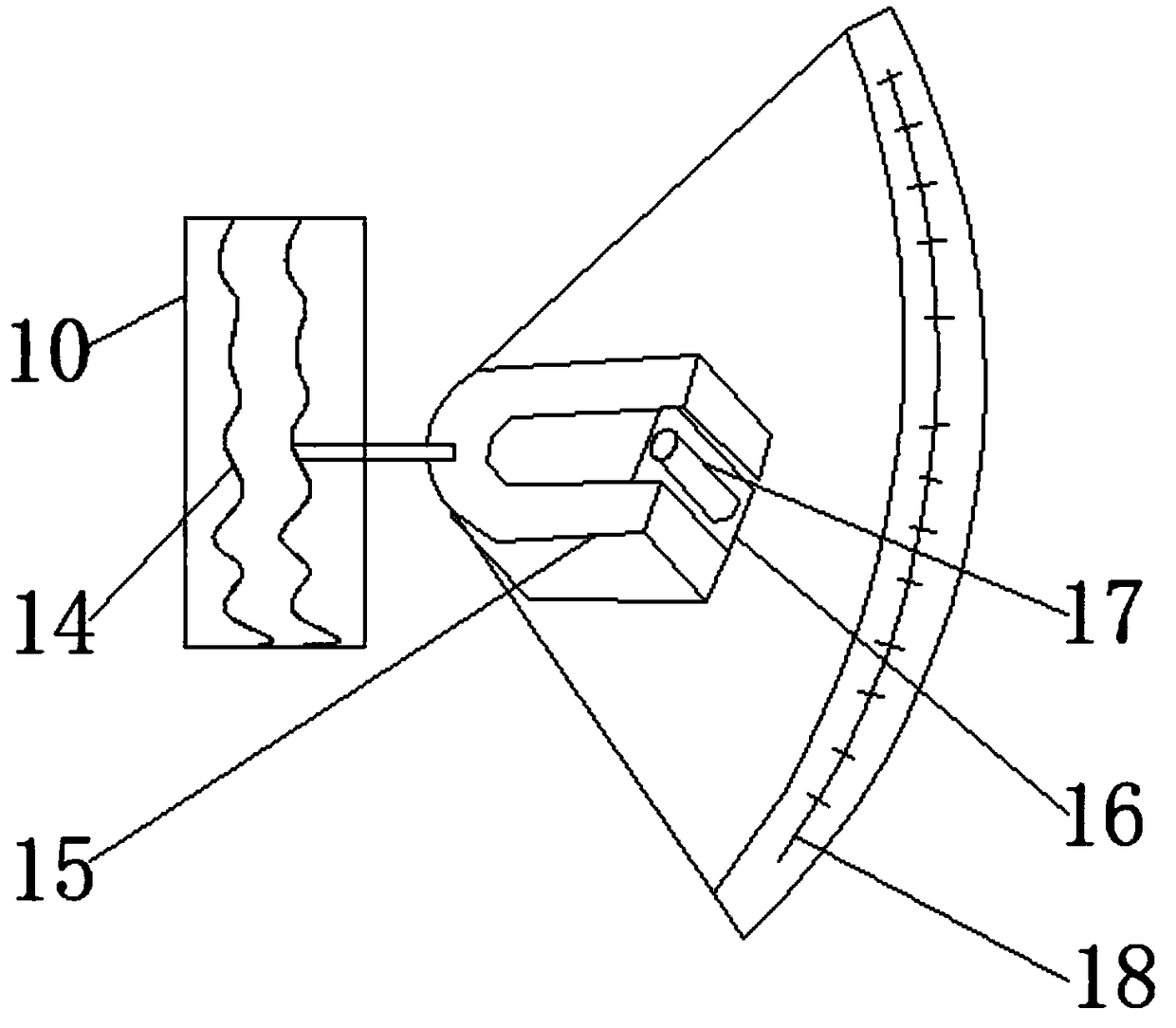

[0032] One side of the fixed frame 5 is fixed with a sensitive thermometer 10 at the middle position of the fixed crossbar 6, and one side of the sensitive thermometer 10 is fixedly equipped with a humidity sensor 11. By setting the sensitive thermometer 10, the temperature detection of the cloth rack can be improved. Sensitivity prevents the temperature of the cloth from being too high or too low, and more accurately guarantees the placement temperature of the cloth. The inside of the sensitive thermometer 10 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com