Intelligent husked rice separation machine

A paddy separator, intelligent technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of separation point fluctuation, increase of screening error, high maintenance cost, etc., and achieve reasonable structure design and mechanism design , Improve the effect of output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

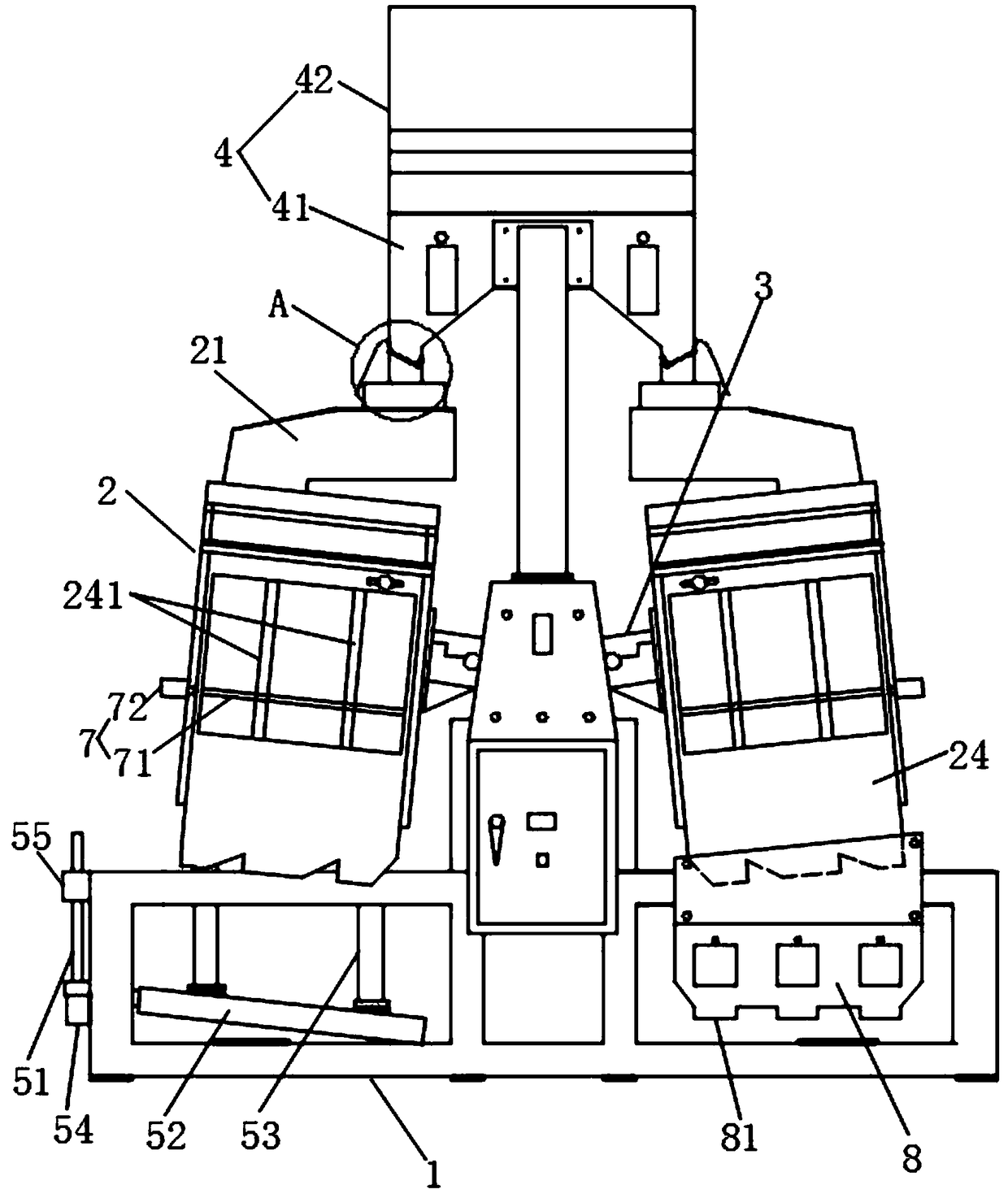

[0037] Embodiment one: if figure 1 , 3 As shown, the intelligent rice-rough separator of the present embodiment comprises a base 1, a vibration screening mechanism 2, a vibration mechanism 3, a feeding device 4, an angle adjustment mechanism 5 and a central processing unit;

[0038] The above-mentioned vibration screening mechanism 2 is arranged on the above-mentioned base 1, and its upper end is provided with a feed port, and its lower end is provided with a discharge port, and the above-mentioned feed device 4 is connected with the above-mentioned feed port;

[0039] The above-mentioned vibrating mechanism 3 is fixed on the above-mentioned base 1, and is connected with the above-mentioned vibrating screening mechanism 2 to drive the above-mentioned vibrating screening mechanism 2 to vibrate;

[0040]The above-mentioned vibration screening mechanism 2 has multiple layers of screening plates 25 arranged at intervals up and down, and one side of the above-mentioned screening p...

Embodiment 2

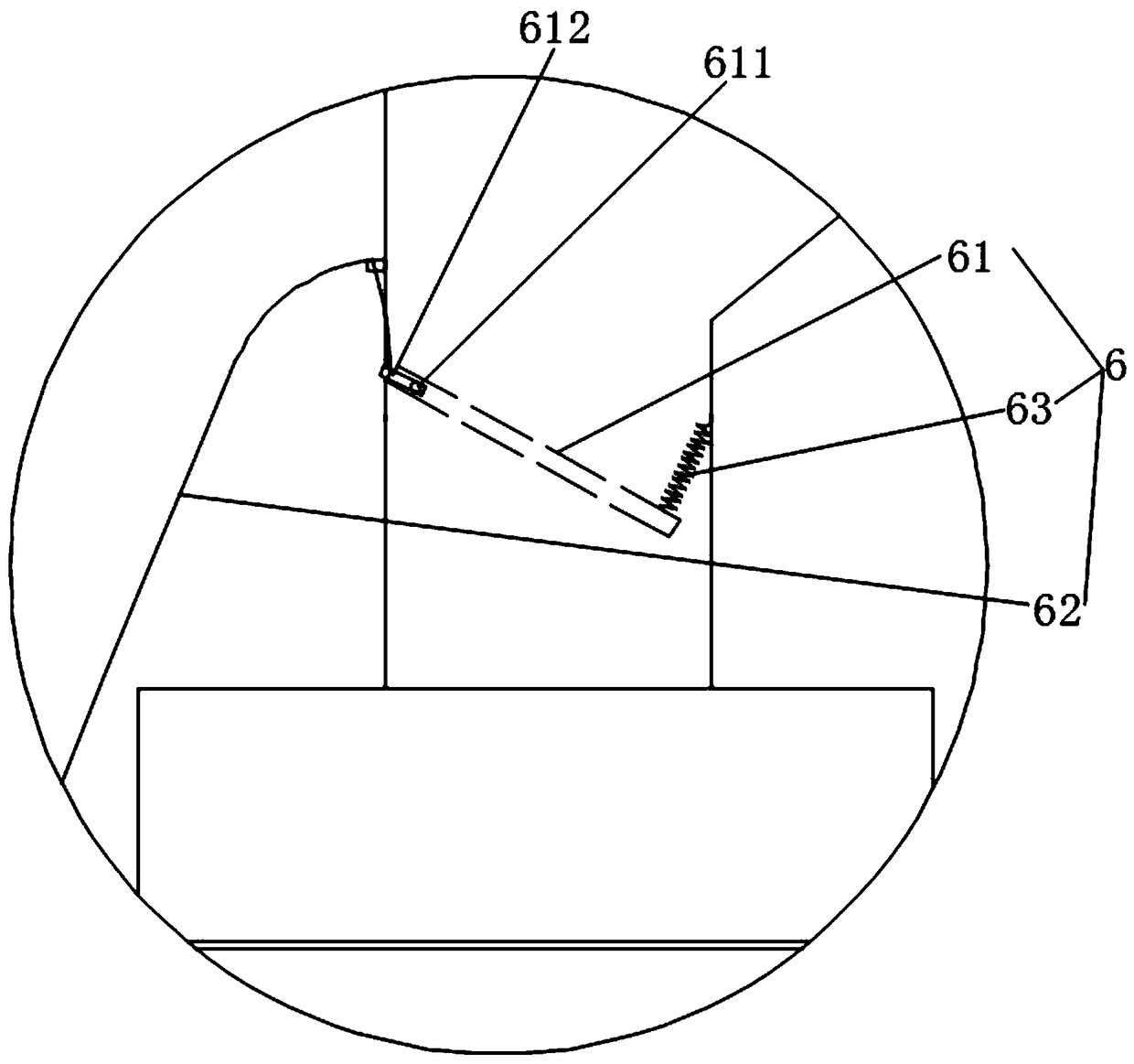

[0048] Embodiment two, such as figure 1 , 2 As shown, it also includes two flow regulating mechanisms 6, the two above-mentioned flow regulating mechanisms 6 correspond to the two above-mentioned feed bins 41 respectively, and are used to control the feeding amount of the corresponding above-mentioned feed bins 41 respectively, through The flow regulating mechanism 6 can adjust the grain entering each vibrating screening mechanism 2 according to the actual processing conditions, that is, adjust the distribution state and layer thickness of the grain on each layer of screening plate 25, so as to ensure that the equipment achieves high output and high quality screening When starting up, the flow regulating mechanism 6 is used to gradually increase the feeding amount. The camera monitors whether the material on the upper screening plate 25 can be covered with the screen surface. The program automatically drives the angle adjustment mechanism 5 to adjust the angle of the vibratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com