Wide-particle-grade coal slime flotation method

A coal slime flotation and coal slime technology, applied in flotation, solid separation, etc., can solve the problems of easy desorption of coarse particles, high ash content of clean coal, complex system, etc., and achieve significant economic benefits, equipment investment and power consumption Small, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

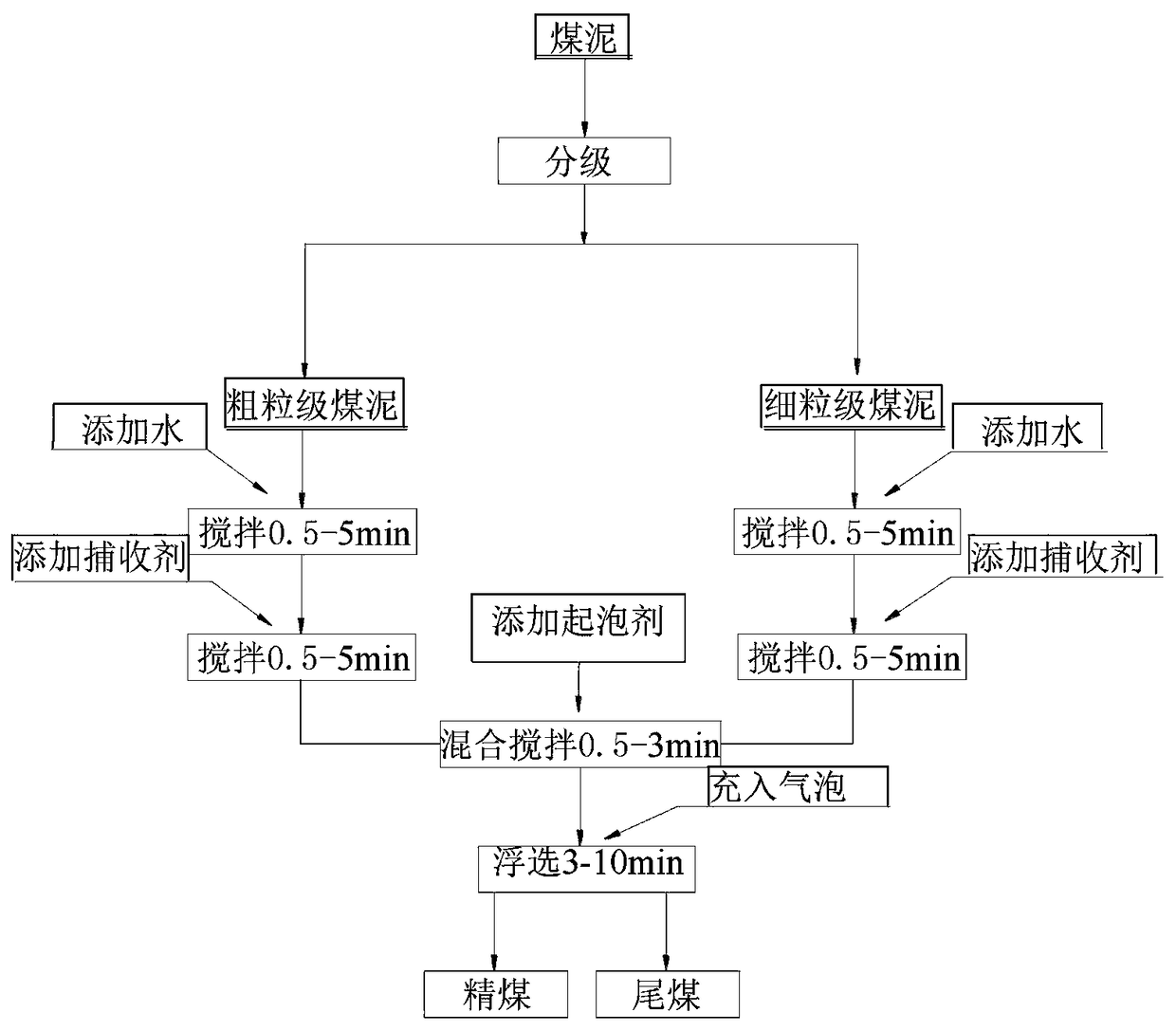

[0024] a. The coal slime was sieved into two grades: +0.25mm coarse grade slime and -0.25mm fine grade slime. In this embodiment, the coal slime can also be classified by other means, such as cyclone classification, etc., and there is no substantial difference to the method of the present invention.

[0025] b. Add tap water to coarse-grained coal slime and fine-grained coal slime respectively, and stir for 0.5-5min to prepare coarse-grained ore pulp and fine-grained ore pulp respectively. 10%. In the method of the present invention, the stirring time is a non-quantitative technical requirement, and the length of the stirring time can be adjusted according to the actual situation (the same reasoning follows).

[0026] c. Add collectors to the coarse-grained pulp and fine-grained pulp respectively. The collector is kerosene, and the dosage is 6kg / (dried coal slime t). Stir for 0.5-5min.

[0027] d. Transfer the two pulps treated in step c to a flotation tank for mixing, ...

Embodiment 2

[0031] It is basically the same as the embodiment, except that the solid mass percentage concentrations of the coarse-grained pulp and the fine-grained pulp are both 20%. The collector is diesel oil, the dosage is 0-10kg / (dried coal slime t), the dosage of coarse-grained pulp collector is 10kg / (dried coal slime t), and the dosage of fine-grained pulp collector is 1kg / (dry coal slime slime t). The foaming agent is ethanol, and the dosage is 2 kg / (dried coal slime t).

Embodiment 3

[0033] Basically the same as Example 1, the difference is: the solid mass percent concentration of the coarse-grained pulp and fine-grained pulp is 5%, and the collector is selected from dodecane, and the consumption is 0-10kg / (dry Coal slime t), the amount of coarse-grained pulp collector is 2kg / (dried coal slime t), the dosage of fine-grained pulp collector is 1kg / (dried coal slime t), the foaming agent is fusel alcohol, and the dosage is 0.05kg / (dry slime t).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com