A DC vacuum circuit breaker

A vacuum circuit breaker and branch circuit technology, which is applied to high-voltage air circuit breakers, circuits, high-voltage/high-current switches, etc. Contact effective area and other issues, to achieve the effect of stable and lasting longitudinal magnetic field strength, reducing loss, and improving high current breaking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

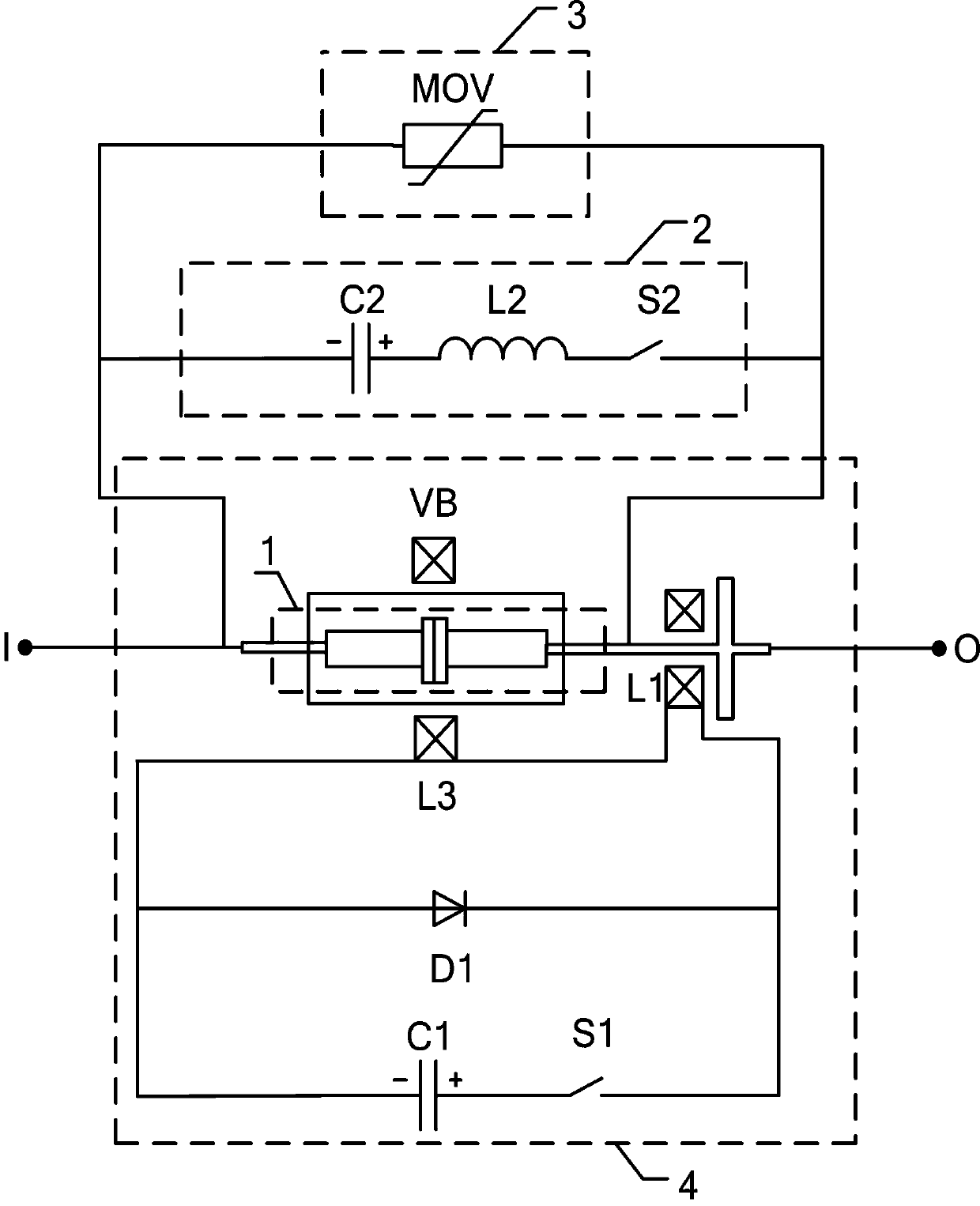

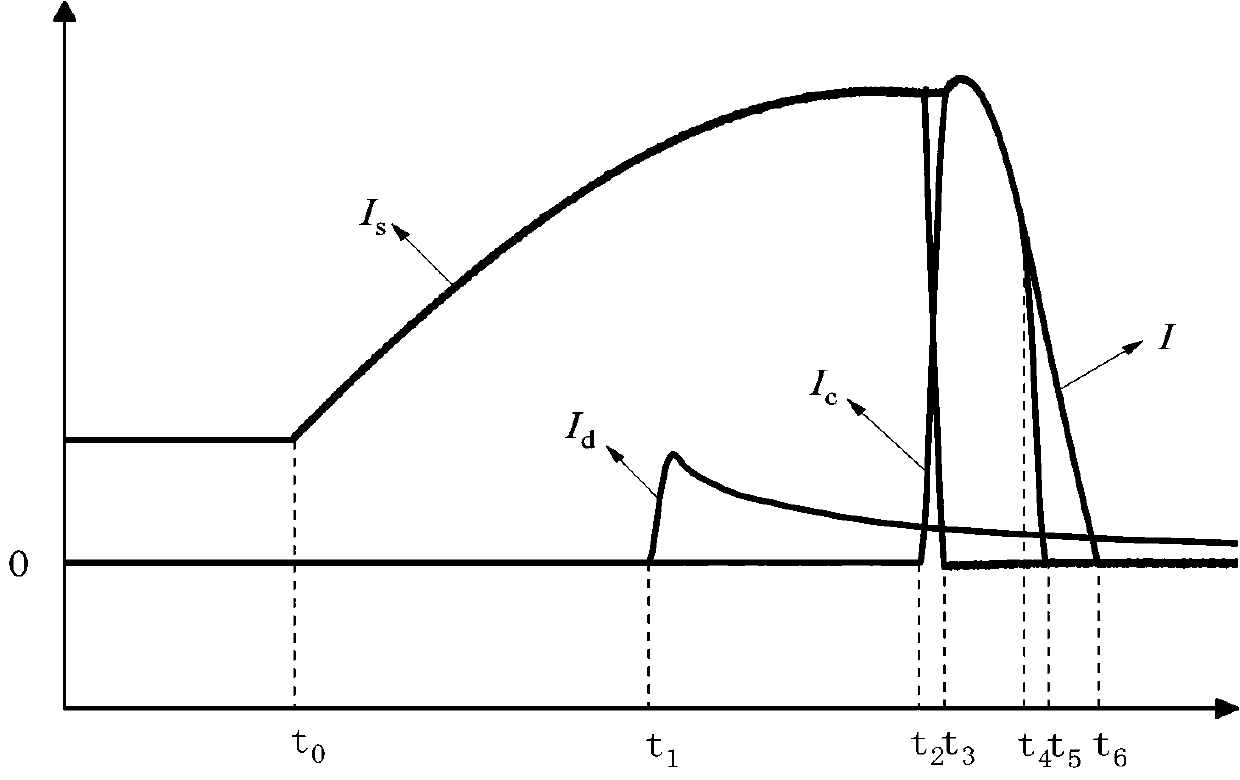

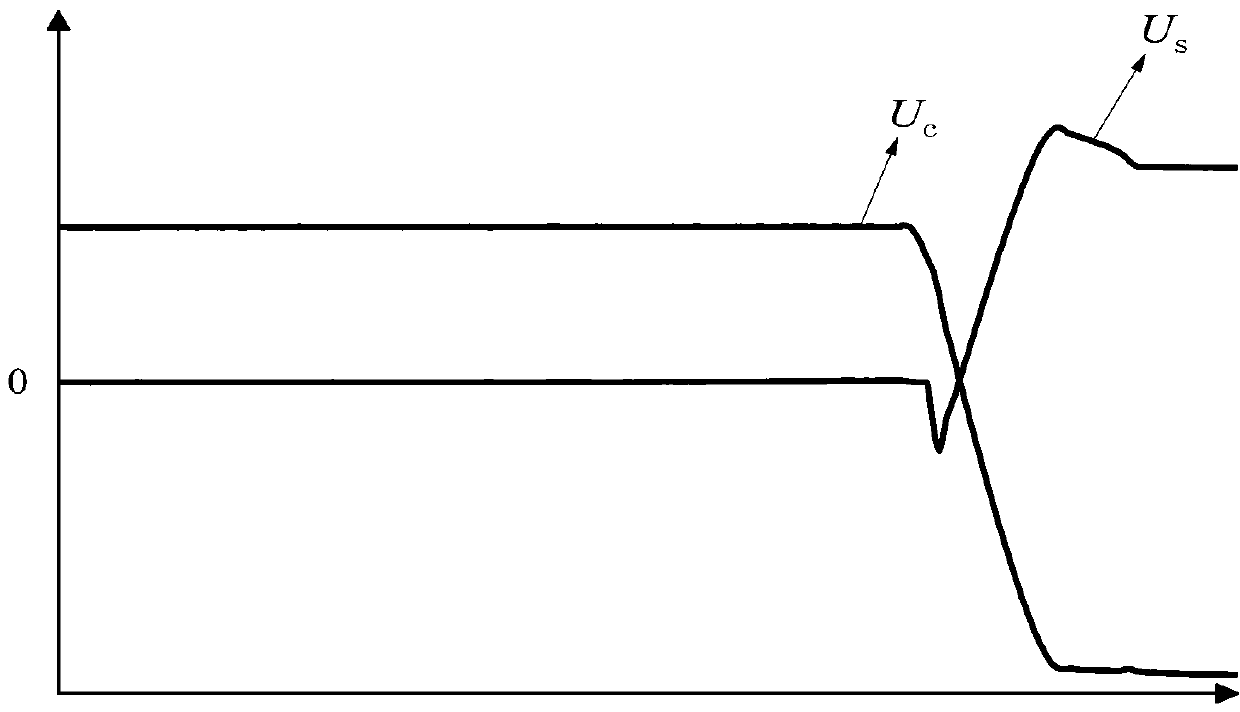

[0025] The invention discloses a DC vacuum circuit breaker. The opening mechanism adopts an electromagnetic repulsion mechanism based on a repulsion disk and a repulsion coil, and includes a normal flow branch 1, a commutation branch 2, an energy absorption branch 3 and a magnetic field generation branch. 4. The normal flow branch 1, the commutation branch 2, and the energy absorption branch 3 are connected in parallel; when the normal flow branch 1 is working normally, the fast vacuum switch VB in the arc extinguishing chamber is closed gate through the system load current. In the normal working state of the DC power system, the fast vacuum switch VB in the normal flow branch 1 is in the closed state, and the load current is borne by the fast vacuum switch VB.

[0026] The commutation branch 2 is composed of a commutation capacitor C2, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com